Construction of the new Storstroem Bridge

| Information on the new Storstroem Bridge |

| Construction price: appx. 4.1 billion DKK |

| Construction started: 2018 |

| Construction finished: 2022/2023 |

| Lenght of the Bridge: appx. 4 km |

| Clearance below: avg. 26 meters |

| Max speed cars: 80 km/h |

| Max speed trains: 200 km/h |

| Carrys: 2 train tracks, 2 road lanes, bicycle path & sidewalk |

| Main stakeholder: Ministry of Transportation and Housing, |

| BaneDanmark, and The Danish Road Directorate |

Created by: Johan Kjærsgaard Knudsen s164316, Kristoffer Sundberg Ipsen s164293, Sebastian Skaarup Lind s164299, Jonathan Friis Schouenborg s162692, Narwan Kabir Noori s164019, and Casper Solvang Andersen s164279

The Danish Road Directorate is currently the builder of the new Storstroem Bridge, also known as Storstrømsbroen. The construction of a new bridge and demolition of the old bridge is due to the construction of the tunnel across Feharnbelt which will result in an increased amount of mainly cargo trains using the railroad from Ringsted to Germany. The construction of the new Storstroem Bridge is only a part of the renovation of the aforementioned railroads done by BaneDanmark. The choice of building a new bridge instead of renovation the old bridge is due to lower socio-economic expenses that would otherwise have resulted in a shutdown of traffic on the bridge in serval years.

Contents |

Collection of Tools

Critical Chain Project Management (CCPM)

Critical Chain Project Management (CCPM) is a method of planning, execution and managing projects. CCPM depends on three core principles: relative global urgency, clear stable priorities, and relay race culture. Using these core principles, also found in the critical chain approach, and focusing on the resources and not the different tasks CCPM should be able to speed up projects by 30% and increase the predictability up to around 90%. To conclude the main principle with CCPM is to remove the risk of delays, speed up projects and improve the predictability and instead have a time buffer that can be used. [1]

Change Orders (CO)

Change orders (CO) [2] are a general change from the original plan, e.g. in the project plan and the planned design, which are a common issue within the construction industry and usually result in delays and increased expenditures in the execution of the project. It is normal to see a 10-15% increase in the budget when COs not are included in the original budget. Thus, it is desirable to reduce the total amount of COs within a project. CO will always be cheaper when ordering it early in the project compared to late in the project due to neglection of redoing things.

Common Parameters Causing CO

- Bad Soil

- Material change

- Collision of structures

- Wrongly estimation of budget

- Quality does not live up to the expectations stated in the contract

- Bad communication and confusion

Reduce the Amount of CO

Building Information Modelling (BIM) can be a thing to reduce the amount of CO since it uses 3D drawing models (for instance with Solibri), that can compare structural models with the architect’s model. This will remove the uncertainty regarding the collision of structures within the project. Subsequently, this also gives a better cost estimation due to all component’s inclusion in the original plan. As a matter of integrating virtual reality, the property developer can visualize the building beforehand. Hence, the quality that does not live up to the expectation will be reduced. Another to reduce the amount of CO is to include the end-users through questionnaires or focus groups.

Ways to Manage CO

Two types of CO exist namely, a required and an elective. The required is a compulsory change that has to be made due to law requirements and that safety standards are not meet. The elective one is mandatory and is only due to the improvement of the existing project. When one of the above COs is to be executed, this should be included in the contracts with respect to the cost, which can be done in three ways. First, the unit price, which was already agreed upon in the beginning, second the lump sum, which is a detailed described of the new work scop and thereby a fixed cost and last the time & materials, which reflect the cost associated with the actual cost and material overrun for each day. The last solution is usually used, when the lump sum is hard to define. Subsequently, one of the following forms can be used between contractor and owner:

Deviation form: when extra work is added to the original scope from the contractor, which can be rejected or accepted by the owner.

Initiator change order request: Forecasted extra work to do the change.

Change order technical justification: Document of reliability which states the extra work needed.

Changes Within the Project

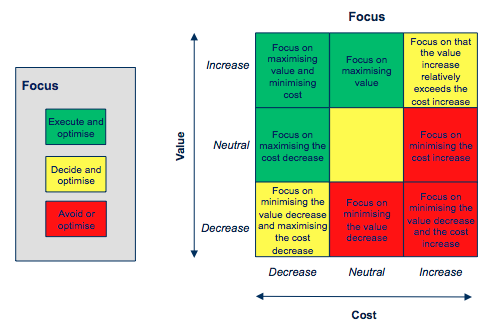

Changes within a project happen often and it is important for the project manager to learn how to deal with these changes. The change matrix to the right is a tool that provides a helpful overview of different changes within the project and how to deal with these changes. On the y-axis is the value of the project and on the x-axis is the cost of the change to the project. The optimal location to be for a project in the upper left corner (green). This is due to the fact that you increase the value of the project with the lowest possible cost/cost increase of the project. As a project manager, you should try to execute and optimize this field as much as you can. On the other hand, it is the lower right corner of the matrix. Here the change initiative will decrease the value of the project and increase the cost of the project. As a project manager, you should try to avoid or try to optimize the change in a way that will provide a better outcome of the project. The yellow areas of the matrix are areas that you as a project manager should watch and optimize. Here you should simply figure out how to reduce the cost and still maintain your high value of the project or make sure that the cost does not increase but that the value of the project will increase.

Triple Constraint Theory

There are multiple constraints associated with doing projects, but overall the constraints can be divided into three overall categories: Scope, Cost and Time. These categories form what is called the triple constraint theory or the iron triangle. Picture XXX to the right shows the triple constraint theory.

According to ISO standard 12500 states that a change in one of the constraints will affect the others. A general rule of thumb states that a project manager can only focus on two out of three constraints leaving the third to be determined based on your choices with the two constraints.

A limitation of the iron triangle is that you are likely to oversee the complexity of the project by making it simpler. This could potentially shift the focus from the origin of the project.

Management Reserves Vs. Contingency Reserves

When you are creating a project budget you often take three aspects into account: Cost estimate, Contingency reserve, and Management reserve. The cost estimate is as the word indicates an estimation of the cost of the project. The contingency reserve is a reserve that is used to be prepared for known unknown factors this could i.e. be significant changes in the scope of the project, unforeseen extreme weather conditions. The cost estimation and the contingency reserve represent the cost baseline of the project. In addition, the management reserve. It is only the project manager that is able to control this reserve. Management reserves is to control unknown unknowns and is determined by the organization. The three of these combined makes the project budget.

Cost Estimation Techniques for Projects

Before a project manager even starts a project is it vital to know an estimation on the total price of the project which always will be questioned by the stakeholders. In order to make a fast and accurate estimation of the total cost, a set of techniques and methods can be used by the project manager. These methods and techniques differ from each other in both time and resource consumption but may vary in accuracy. For project managers, all possible parameters have to be considered and the usage of all appropriate techniques for each specific project or a combination of techniques. [4]

PESTEL Analysis

A PESTEL analysis is an extended version of the PEST analysis and it contains political, economic, social, technological, environmental and legal aspects. The manager can apply this to analyze and monitor macro-environmental factors that may have an impact on the organization. A PESTEL analysis is often applied in combination with a SWOT analysis where you are looking at strengths, weaknesses, opportunities, and threats to a company or a special case of the company. The political factor is the degree to which the government intervenes with a specific industry. The initiatives could, for instance, be; tax increment/decrease, laws, and regulation (including laws to protect the environment). The economic factors include economic growth, interest rates, inflation, unemployment rates, and etc. The economic factor influences the purchasing power of a company. The social factors include norms and cultural aspects, the value of customers, demographics. The social factor includes factors like the growth rate of the population, income and the distribution hereof, health consciousness, and etc. The technological factor include the department of research and development (R&D), the degre of innovation, the technological awareness.

Bibliography

- ↑ http://wiki.doing-projects.org/index.php/Critical_chain_project_management_(CCPM) visited 03-03-2020

- ↑ http://wiki.doing-projects.org/index.php/Change_order visited 03-03-2020

- ↑ 3.0 3.1 http://wiki.doing-projects.org/index.php/Management_of_Project_Change visited 03-03-2020

- ↑ http://wiki.doing-projects.org/index.php/Cost_Estimation_Techniques_for_Projects visited 03-03-2020

- ↑ https://www.professionalacademy.com/blogs-and-advice/marketing-theories---pestel-analysis visited 03-03-2020