Risk

By Shakila Khan Malik s173780

Contents |

Abstract

Risk is associated with everything, even when we talk about projects. It is important to keep risk in mind when working on a project, program and portfolio and identify them, as risk can lead to large costs, losses and project failures. The purpose of the article is to identify potential risks and put them into perspectives using risk management tools.

In order to identify and prevent risks in a project, it is necessary to have risk management. Risk management is a process for identifying risks in a project. Multiple tools can be used to reduce and prevent risks and uncertainties during a process or project. The aim is to ensure successful projects without major risks and unexpected events leading to high costs.

One of the risk management tools is “Failure mode and effects analysis” (FMEA). The FMEA is a process that identifies how and where the project might fail and assesses the different failures to identify which parts are most in need of change [1]. In addition, another management tool, the “fishbone diagram” can be used to track the causes of deficiencies or failures in the project. Some other risk management tools are “Post-project review” (PPR) and “Potential problem analysis” (PPA). The PPR analysis identifies potential failures and successes in a project, where the PPA determines what may go wrong in a process or development phase.

Tools

As mentioned earlier, this wiki article contains several risk management tools, that can be used to manage a project. These tools can be adopted by the managers in any organization as the tools are guidance how to tackle and prevent risks and uncertainties in a project or program.

Failure Mode and Effects analysis (FMEA)

The FMEA was developed in 1940s when the U.S. military systems became too complex. The FMEA tool identifies where the project might fail, and which parts are most in need of change to prevent risks and uncertainties. The FMEA tool can solve several risks in a manageable way. The failures are prioritized by their consequences and frequency, starting with the highest priorities [2].

The FMEA consists of 7 steps:

- The first step identifies the failures that might fail in the project. The management team has to define the scope.

- The second step identifies the root causes of the failures in the project. All processes are divided into subsequent steps.

- The third step identifies the effects of the failures. Each failure is analysed separately to identify the largest failures.

- The fourth step critically identifies and prioritizes the failures, starting with the highest priority.

- The fifth step mitigate the failures and limits the failure modes.

- The sixth step is optimization and develops actions to prevent risks and uncertainties. The actions reduce the likelihood of failures and improve processes, products and services.

- The seventh step is the result, where the results of the FMEA are documented.

When and why should the tool be used

The FMEA tool is often used through a product, process and service design phase, before modifying an existing process in a different way and generally to analyse the failures of a project.

The benefits of using the tools are that the failures are identified in an early stage and prevent risks and uncertainties. Furthermore, the FMEA allows to a greater extent changes in the processes, products and services as it is possible to mitigate the risks. Moreover, it is cheaper solutions. [3]

Potential problem analysis (PPA)

Another risk management tool is “Potential Problem Analysis”. The PPA implement innovation and focus on what might happened during the developing phase and how to deal with it. The tool determines what could go wrong in a project or process. The causes are assessed as the probability of occurrence and the difficulty of the consequences. [4]

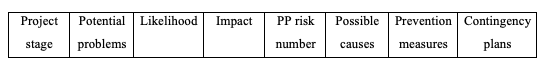

The PPA tool consists of 7 steps [5]

- The first step is to identify the objectives by producing a flowchart.

- The second step is to list the potential problems by making a brainstorm with the problems.

- The third step is to rate the potential problems in terms of likelihood.

- The fourth step is to determine the risk number of the problems by multiplying the two numbers.

- The fifth step is to search for possible causes of the problems using a fishbone diagram.

- The sixth step is to estimate the probability of occurrence and try to prevent them.

- The seventh step is to develop actions to prevent causes or minimizing their effects.

The tool is primary used when working on a large and complex project. Moreover, to meet deadlines without investing a lot of time and money on risk and changes, solving future problems and prevent uncertainties. The tool prioritizes which problems need to be addressed immediately, however is it hard to rate risks. [6].

Post-project review (PPR)

Post-project review is a management tool that gives the opportunity to learn from previous projects. The purpose of the tool PPR is to analyze potential failures and successes of a project or process. It simplifies what went well and what could be better in a project. It minimizes risks and uncertainties as it is possible to learn from previous experiences and failures to improve future projects.

Proc and Cons

There are both proc and cons associated with this tool. For structured frameworks, the tool is fantastic as it is possible to use it slavishly and thus save time as well as duplications. Furthermore, it can be seen what went well and what could be improved. On the other hand, some of the cons are that the previous projects are followed too much that the managers don’t think about improvements, changes or innovation. Another con is that project managers are often not prepared for unseen events in the project. [7].

When to use the tool

The PPR tool is useful for large projects especially within IT as IT companies usually need formalized innovation strategy. The tool avoids uncertainties and duplications as using the tool lead to decreasing in prework. Furthermore, it makes sure that failures from previous projects don’t appear again in future projects.

References

- ↑ http://www.innovation-portal.info/toolkits/fmea-failure-mode-effect-analysis/

- ↑ ASQ. (2020). Learn about quality. Retrieved from Failure mode and effect analysis (FMEA): https://asq.org/quality-resources/fmea

- ↑ Quality-One International - Discover the value. (2020). Quality-One International - Discover the value. Retrieved from Introduction to Failure Mode and Effects Analysis (FMEA): https://quality-one.com/fmea/

- ↑ http://www.innovation-portal.info/wp-content/uploads/Potential-problem-analysis.pdf

- ↑ https://hatrabbits.com/en/potential-problem-analysis/

- ↑ https://www.kepner-tregoe.com/lp/problem-solving-and-decision-making-workshop/

- ↑ http://www.innovation-portal.info/toolkits/post-project-reviews/