Kanban framework

From DTU ProjectLab

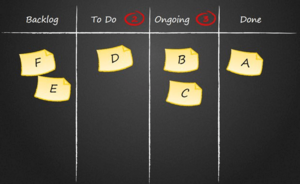

Figure 1: Example of a simple Kanban board [1]

Contents |

Abstract

Kanban can be referred to as either a method within process improvement and management or in Lean manufacturing, following article will be focusing on its uses in process improvement and management.

Kanban is a japanese word meaning signboard, and is used as a methodology to improve processes.

Historical State of the Art

Description of how Kanban first originated and in which context is was developed. Furthermore how the Kanban method has been adopted into system development.

Kanban in Project Management

- Start with what you do know

- Agree to pursue incremental, evolutionary change

- Initially, respect current roles, responsibilities and job titles

Use ref: Managing Successful Projects with PRINCE2 2017 Edition

Features of the Kanban framework

Visualize

Describe kanban cards and boards

Limit work in progress

Manage flow

Make process policies explicit

Implement feedback loops

Improve collaboratively, evovle experimentally

Limitations of the Kanban framework

Describe what limitations there has been found when working with the Kanban framework

Annotated Biography

References

Other notable references not yet used: Books:

- Learning Agile: Understanding Scrum, XP, Lean and Kanban. By Andrew Stellman & Jennifer Greene

- Kanban: Successful evolutionary change for your technology business. By David J. Anderson

- The Lean Toolbox: A handbook for lean transformation. By John Bicheno & Matthias Holweg

Websites:

Articles:

- Identification of criteria affecting software project monitoring task of Agile Kanban method. By Hamzah Alaidaros, Mazni Omar and Rohaida Romli

- https://aip-scitation-org.proxy.findit.cvt.dk/doi/pdf/10.1063/1.5055423

- Collaborative Work Management with a Highly-Available Kanban Board. By Annette Bieniusa, Peter Zeller, and Shraddha Barke

- file:///Users/JakobWeber/Downloads/5bd0583fd9001d01d4104a4f.pdf