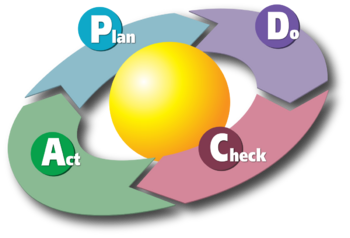

PDCA cycle

"It [The PDCA cycle] is a flow diagram for learning and for improvement of a product or of a process." [1] W. Edwards Deming

The PDCA (Plan-Do-Check-Act) cycle, also known as the Deming cycle or the Shewhart cycle, is a project management method used to continuously improve the quality of a process or a product. This cycle is based on the four following phases: Plan, Do, Check, and Act.[2]

- In the Plan phase, the problem to tackle is identified, and an action plan is set up.

- In the Do phase, the plan is put into action by the project team.

- In the Check phase, the differences between the results and the expectations are evaluated.

- In the Act phase, corrective actions are taken in order to improve the evaluated situation.

By breaking down a complex problem into these four phases, the organization obtains a clear overview of the situation and is forced to systematically identify areas of improvement, take actions about it, compare the results and the expectations, and make the necessary adjustments.

The PDCA cycle is an iterative method, which means that at the end of the fourth phase, it is recommended to implement again the method on the new situation to continue the improvement of the product or the process. This iterative approach results in an increase of efficiency and effectiveness inside the organization.

Developed by Eric Vincent Vong

Contents |