Earned Value Management (EVM) in construction projects

The Us federal government introduced Earned Value management(EVM) in 1967 as a part of the cost/schedule control systems criteria (C/SCSC) Earned Value management is a systematic process that is used to measure the performance of a project at different times throughout the life cycle of a project. EVM is useful to help project managers or people in general that are responsible for a project to determine whether a project is on schedule, or if the project is over or under budget. EVM can also be used to compare the actual work that has been performed to the work that was estimated and planned for the project at a certain time during the project, EVM can also be used to forecast projected performance. EVM is a technique that can be applied, to at least some degree, to the management of projects in any industry and using any contracting approach. http://onlinelibrary.wiley.com.proxy.findit.dtu.dk/doi/10.1002/pmj.20272/pdf

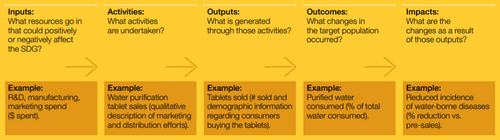

EVM measures project progress and performance by the integrated management of three fundamental elements of project management, cost, schedule and scope as can be seen in figure Xhttp://www.ambysoft.com/essays/brokenTriangle.html

Contents |

History

Concept overview

Implementation of the method

The following parameters are used to asses and compare in EVM

| Parameter | Description | Formula |

|---|---|---|

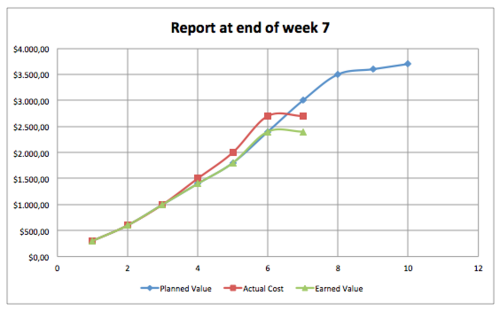

| Planned Value (PV) | Is a budget baseline that has been established for a project/work package/activity. It is a function of cost and time as can be seen in figure 1. PV baseline can be used to view the value to be earned at a certain time/phase in the project. PV is frequently referred to as the S curve simply because of the shape of the curve

| |

| Budget at completion (BAC) | BAC is the final point and the highest value of the cumulative Planned value curve. BAC represents the total budget for the project/work package/activity.

| |

| Actual Cost (AC) | Is the cumulative actual cost that has been spent on a project/work package/activity

| |

| Earned value (EV) | is the cumulative value that has been earned for the work completed at a certain point in time. | Earned value(EV)=total budget for activity*completed proportion |

| Earned Value Variances | Description | Formula | BLAA |

|---|---|---|---|

| Cost Variance (CV) | o | = Earned Value (EV) - Actual Cost (AC) | > 0 means under budget

< 0 means over budget |

| Schedule Variance (SV) | o | = Earned Value (EV) - Planned Value (PV) | > 0 means ahead of schedule

< 0 means behind schedule |

| Earned Value Indices | Description | Formula | BLAA |

|---|---|---|---|

| Cost Performance Index (CPI) | o | = EV/AC | > 1 means better progress for the money spent

< 1 means less progress for the money spent |

| Schedule Performance Index (SPI) | o | = EV/PV | > 1 means more work performed than had been scheduled

< 1 means less work performed than had been scheduled |

| Project Percent Complete | o | = (EV/BAC) * 100 | Percent of project work complete at a given time.

Remember BAC = Budget at Completion |

| To Complete Performance Index (TCPI) | o | =(BAC-EV)/(BAC-AC) | The cost performance index required to complete the project on the predetermined budget. |

| Earned Value Forecast | Description | Formula | BLAA |

|---|---|---|---|

| Estimate at completion (EAC) | o | = BAC/CPI | The estimated total cost at project completion. |

| Variance at completion (VAC) | o | = BAC-EAC | The estimated variance between actual total cost(EAC) and planned total cost(BAC) at project completion. |

Terminology

Example

In this section there will be an short simplified example of EVM in a project that has five tasks A,B,C,D,E. Figure 1. Step 1 For each of the tasks the duration has been estimated, the cost of each task per week and finally the total cost of each task. These cost are called Planned value(PV) in EVM. In more detailed examples and projects a Work Breakdown schedule"(WBS) can be very useful if used in the right ways.

| Task | Predecessor | Duration(Weeks) | Cost/Week | Total Cost |

|---|---|---|---|---|

| A | 2 | 300 | 600 | |

| B | A | 3 | 400 | 1200 |

| C | B | 3 | 400 | 1200 |

| D | B | 2 | 200 | 400 |

| E | D | 3 | 100 | 300 |

| 3700 |

To keep track of the status of each of the projects a Gantt Chartt has proven to be very useful since it provides much needed clarity, helps with coordination and last but not least time management, helping teams understand the overall impact of project delays which is an vital part of the EVM method. In this Gantt chart there can be seen the planned schedule and the actual performance of the project up until week 7 when the project manager decided to take a closer look at the progression of the project.

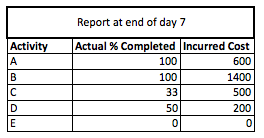

His report at the end of week 7 can be seen in table 2. Using the data from that table to fill up the GANTT Chart. According to the report and from the GANT Chart it can be concluded that task C and D are behind schedule.

| Task | Planned completion | Actual completion |

|---|---|---|

| C | 66% | 33% |

| D | 100% | 50% |

Now it is time from the project manager to analyze the situation and take a closer look at the Earned Value Variances(, Earned Value Indices and Earned Value Forecast

The project manager made some calculations which can be seen in table 3.

| Task | Schedule Variance (SV) | Cost Variance(CV) | Schedule Performance Index(SPI) | Cost Performance Index(CPI) |

|---|---|---|---|---|

| A | Exactly on schedule | Exactly On budget | Exact amount of work performed that has been scheduled | Exact amount of progress for the money spent |

| B | Exactly on schedule | Over budget | Exact amount of work performed that has been scheduled | Less progress for the money spent |

| C | Behind on schedule | Over budget | 50% of work performed that has been scheduled | Less progress for the money spent |

| D | Behind on schedule | Exactly on budget | 50% of work performed that has been scheduled | Exact amount of progress for the money spent |

| E | - | - | - | - |

Advantages

The use of EVM to make progress payments on construction projects.

When undergoing a project there is often a risk that the owner of the project is going to overpay their suppliers for the work they completed. This is due to the fact that Cost-type arrangements have inherent risk for the sake of the owners focusing on the expense paid and forgetting to closely monitor the actual work done for the money spent. One way of mitigating this risk is to accurately measure the value of work completed, compare that against the original budget authorized for the completed work, and only pay for actual work completed. There are two broad contractual environments in the building industry, Cost type and fixed price

Cost type

Is often used in construction projects to cover the initial design work and both the first and final design. In project that are high risk, f.x. nuclear energy construction the cost type contract is sometimes used for all of the phases of the project.

Cost reimbursable type arrangement works in the following manner: the supplier will be refunded each month for the actual cost(AC) during the project, which is subjected to the terms of their agreement, meaning that all costs (excluding fee) are submitted by the supplier/contractor to the owner, who pays the bill. Because of this arrangements there can be a substantial difference between the physical work done and the dollars being spent on the project. Quentin W. Fleming and Joel M. Koppelman provide four recommendations to reduce the risk for cost type contracts

1. Project owners should order the supplier/constructor to provide a "schedule of values" which is time-phased, and the sum of all items will be listed up to the total contract value. This time-phased schedule provides the owner a valuable and simple form of "planned value(PV)" which can be used to measure the performance of the project through its life cycle

2. At the end of each month, when the supplier/contractor provide their invoice that reflect the Actual cost(AC) incurred, order the contractor to update their schedule of values, which is the Earned value(EV) of the project. This gives the owner a tool to monitor the earned value against the planned value and the earned value minus the actual cost to get the cost variance of the project

3. It can be useful to monitor the performance of both the cumulative Cost Performance index(CPI) and the Schedule Performance Index(SPI) to compare the results of one project to all other projects with similar circumstances in the company.

4. Forecast the likely final cost at regular intervals with the Estimate at completion (EAC) method to ensure that the project is on budget, and if it is not make the necessary adjustment to stay on track

Fixed price In most fixed price contracts suppliers/contractors are given progress payments based on the amount of work completed, along with the authorized budget for the completed work. This method is highly useful with the Earned Value Management method. Effective method to establish an earned value baseline could be to require the supplier/contractor to make a "critical path method(CPM) LINKA CRITICAL PATH METHOD HERNA GAMLI, with the necessary resources integrated into the CPM model, and the sum of these resources must sum to 100% of the contract value. Actual costs(AC) related to the earned value are oft missing in the fixed price work. If there is no AC then we lack the ability to make up the Cost performance index(CPI), which is one of the most important indicator in the EVM method. Suppliers/contractors who accept a fixed price job are likely to be reluctant to disclose how much profit they are making on the job, actual cost to earned value. The profit that the contractor is set to make should not be concern to the project owner, it's only when the contractor starts to incur a loss, especially a large loss that the project owner could get concerned. This is due to the fact that a loss increased the likelihood that the supplier is unable to complete the job. To mitigate the risk to the owners Quentin W. Fleming and Joel M. Koppelman provide two recommendations

1. Condition all fixed price suppliers to hand over their anticipated costs that have incurred, to match with their planned value(PV) projections contained with either previously mentioned time-phased schedule of values, or their CPM resource loaded model. These costs incurred forecasts usually resemble the "S" shaped curve LINKA HERNA I S-SHAPE CURVE JAFNVEL HEIMILD FYRIR S SHAPE CURVE. Unless there are justifying reasons there forecast should resamble the "S" curve, else the projections may be "front-loaded" TILVITNUN I FRONT LOADED, or the project owner might be paying for work that has not been completed

2. To minimize the financial risk of the project, there could be a good thing to condition the supplier to have their chief financial officer(CFO) to validate each month that they have not exceeded their planned value of cost incurred. On the other hand if the supplier has exceeded their planned value , require them to reveal the amount of their actual cost incurred, so it is possible to compare it to the earned value and be able to quickly determine how much loss the contractor has suffered.