The Kaizen – Toyota KATA method

Overall there are two paradigms within management – the Command and Control Paradigm (CCP) and the Interaction and Learning Paradigm (ILP) [1]. The first one, CCP, would put the manager in the position of an enlightened leader, who has all the answers and operates in a deterministic world. In other words, the manager like the conductor of an orchestra, directs the symphony, giving specific directions to each musician. On the other side, we find the paradigm of interaction and learning, where a manger does not yet have all the answers, but acquires them through interaction. A manager rather than giving detailed action plans, creates a frame for action. It is said that the second approach works better when dealing with complex tasks, varying demands, and unpredictable environments. Within project management these two paradigms are also represented in the form of traditional and agile project management. This article views project management from the ILP paradigm and it assumes that a project or a portfolio manager often needs to deal with problems without having a clear solution. In this situation the right approach always has to do with exploration and innovation.

This article examines a management method, which has proven to be very successful in supporting fast and innovative solutions to complex problems in Toyota, namely Kaizen and the Toyota Kata method. This article states that project and portfolio managers dealing with product or process development and organisational change can benefit from the teachings of Kaizen and Toyota Kata.

The Kaizen method engages manager and employees to think solutions beyond the usual, and ensures continuous improvement, as it breaks the problem at hand into smaller problems, solved one by one using the scientific method[2] of experimentation instead of the usual "implementation" approach. This liberates the solutions as the improvement efforts are allowed to lead to failure and failure is even a welcomed learning. The efforts themselves are encouraged to be small, so that their effect can be controlled and, most importantly, confirmed. An important benefit of the Kaizen management method is the humanisation of the workplace. People working on a Kaizen project feel empowered and full of purpose, as they are not blindly following orders but are part of creating their work environment and procedures. The article starts out by elaborating on the methods origins and later describes the processes and tools needed to use it successfully. Benefits and limitations are outlined and finally, the current and future applications of the method within project management are discussed.

Contents |

Brief history of Kaizen and Toyota Kata

Kaizen

The word “kaizen” is Japanese for "continuous improvement", where “kai” means change and “zen” good. Even though Kaizen is mostly associated with Japan, its origins are quality improvement methods from the United States, brought to Japan by experts such as W. Edwards Deming after World War II. The quality improvement methods were introduced in Japan under the Training Within Industry program (TWI) [3]. TWI, Inc. was company providing management training founded by Lowell Mellen in Cleveland, Ohio and they provided trainings all around the world but had governmental support in Japan, England and New Zealand [4]. The first (out of two) TWI training programs in Japan concerned with Job Instruction, Job Method and Job Relations (“J” programs). To promote the program, prior to its start, TWI developed a training film titled “Four Steps for Improvement” or in Japanese “Kaizen eno Yon Dankai”. The program was delivered in the 1950s. This is when the concept of quality circle groups (group of workers performing the same or similar work meeting regularly to identify, analyse and solve work-related problems) became popular in Japan [5]. Subsequently, the man who was involved in the introduction of Kaizen to Japan, W. Edwards Deming, was given an award by the Japanese Emperor in 1960 and an annual award for achievements in quality of products was named after him (Deming Prize [6]). The term Kaizen actually became famous around the world through the works of Masaaki Imai, in particular, his book “Kaizen: Japanese spirit of improvement” (1985) [7]. He who also founded the Kaizen Institute Consulting Group (KICG) [8].

Toyota Kata

Toyota was one of the companies to very well implement the teachings from TWI and to actually standardize them in the form of the Toyota Production System [9]. The success of Toyota has been so great that western companies have many times tried to follow their ways. This has resulted in the formulation of lean principles and tools. The term “lean” was first mentioned in “The machine that changed the world” [10], a book highlighting the gabs between Toyota and other car manufacturers [11]. The principles are numerous, to mention a few: management of value stream, identification of customer value, the pursuit of perfection while reducing all the kinds of waste, the five whys or going after the root cause of a problem.

There is no doubt that Toyota has been successful. Nevertheless, according to a survey conducted by Industry Week in 2007 found that 74 percent of companies are not having success with their lean program [12]. Mike Rother claims in his book “Toyota Kata” [13] that he has found the reason why Toyota succeeds and the rest have a harder time.

In a nutshell, Toyota Kata are the Kaizen practise in Toyota, practiced so often that have become the instinct reaction to a problem, much like when the right karate move is recalled instinctively in a fight situation. Mike Rother figured this out during his research at Toyota when the answer he got on the questions:

- When do you do Kaizen? When are the Kaizen events held? When do you initiate it a Kaizen activity?

was:

- What do you mean? It is all the time!

How does it work – processes and tools

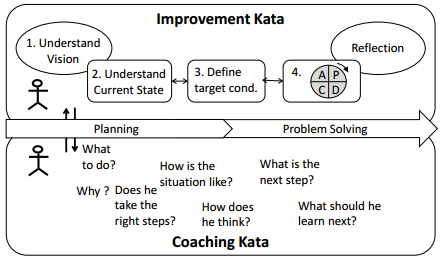

In Lean management, Kata refers to two linked behaviours: improvement Kata and coaching Kata [15]. Improvement Kata deals with the steps that make the improvements possible and it is directed towards the people deciding on and doing the improvements, also know as learners. Coaching Kata can be seen as a supporting process to improvement Kata and it is executed by the people managing the improvements, also know as coaches. The position of a learner is filled by the employee and the position of a coach by his manager and practising Kata becomes integral to the normal daily work. On the different organisation levels, each manager would act as a coach to his employees while being themselves a learner of their manager [16].

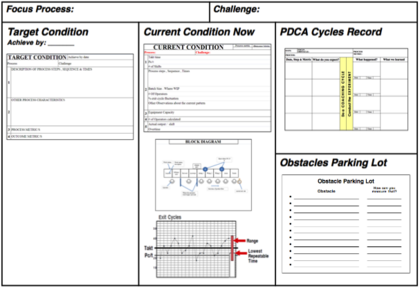

To keep track of the improvements on a certain process and to have structure to each practice, a Learner's Storyboard is maintained (see Figure 2). The storyboard contains all the most important information or the story of what was learned during the improvement initiatives and it is where the overview of the interaction between the coach and the learner is kept. The format of the board, therefore, follows the steps of Improvement Kata. As they are introduced in the following section, details on the different sections of the storyboard will be given.

Improvement Kata

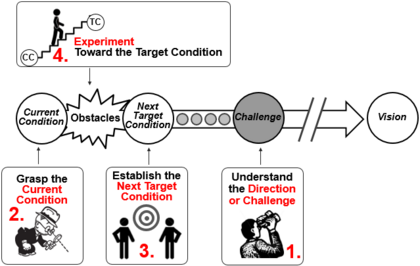

In Improvement Kata there are four steps listed below with details under each step. You can see the steps outlined in the figure 3 on the right, where the number indicates the order of steps.

- Understand the direction or challange

- The vision is the long term goal or the direction giver for an organisation. It is an ideal, stated by the organisation's leadership on a strategic level[16]. Most companies have a vision, which in most cases is being the best in what they do and how it effects the society. Google’s vision, for example, is to organise all of the data in the world and make it accessible for everyone in a useful way. They also have an unofficial motto of not being evil [17]. A vision in the world of portfolio management is the purpose or mission of the program. For example "Lower childhood obesity in the USA" or "Make the live of citizens in Copenhagen less stressful".

- Once there is a direction, it can be deployed into the organisation in the form of more specific challenges or themes, that result in strengthening existing capabilities or developing new ones necessary to move in the desired direction [16]. This challenge is the description of success in six months to three years from now and are the motivator and frame of the Improvement Kata initiatives, as the vision is too far away and it needs to be brought closer [16].

- On the storyboard (Figure 2), the learner would populate the filed in the top right titled "Challenge:" with the challenge for the process she is improving.

- Grasp the current condition

- In this step one needs to carefully and thoroughly examine the the way things are done today. Go down (assuming you are a manager) to where the action takes place and observe. One should be careful to observe for periods of time that are long enough to fully understand the current condition. The results of the observations will define the starting point of the journey towards the challange and will also help determine the threshold of knowledge, or what is believed to be possible.

- At this step one can employ the use of many different tools from the Lean tool box. For example, KPI-s are a good indicator of a current state, showing how well a performance is on a single metric.

- A measure of variation and mean of a product, service or process key delivery can as well be a good indicator of the current capability (e.g. using control charts and capability study [18]).

- It is also common to create a visualisation of the current condition in the form of a process map or value stream map.

- In short, at this step one needs to collect data and facts about the current state, define process and output metrics, so that we know what to improve and with how much.

- On the story board (Figure 2), the learner is concerned with the field "Current Condition Now", where they would display the facts they have gathered. The basic, minimum input here should be a run char, showing the outcome performance and a block or swim-lane diagram showing the process characteristics and operating pattern.

- Define target condition

- While the vision of is the long term goal, and the challenge is the more accessible, but still far in the future goal, the target condition describes the next desired condition one week or three months from now [16]. The path towards the challenge then becomes a series of target conditions. Every time a target condition has been reached, a next one is established.

- Based on the challenge there is usually an outcome performance that needs to be achieved [16]. Combined with the knowledge of the current state, the learner and coach define an ambitions, but achievable target condition and an achieve-by date. The target condition is defined by the two of them, where the learner proposes the condition and the coach gives feedback to it in a back-and-forth manner [16].

- It is important the learner is challenged with achieving the target condition, so that once achieved, it brings a feeling of self-efficacy and accomplishment. Therefore, the target condition should be stretched, just over the learner's capability [16]. This often brings a sense of uncertainty as it pushes people outside their comfort zone, but it is also what humanises the workplace and makes it exciting to go to.

- On the story board (Figure 2), the learner and coach are concerned with the fields "Target condition" and "Obstacles Parking Lot". In the first, the target condition is stated in terms of process output changes. For example, if the current condition is described with process lead time of 8 days, customer satisfaction of 20%, the target condition can be lead time of 7 days and customer satisfaction that is unchanged. In the Obstacles Parking Lot, the learner is asked to identify what prevents her from reaching the target. Some of the obstacles might not be know at this point, but as the improvement initiative commences, they will be discovered and added to the list [16]. Each obstacle should be formulated as a problem not a missing solution. For example, the learner might think that "no standard procedure" is an obstacle, however, it points to a solution - introducing a standard, it should rather be rephrased to "variability in how the work is done". Additionally, each obstacle should be accompanied with an idea of how it can be measured.

- The purpose of the obstacles list is threefold:[16]

- To show that tackling the challenge will not be easy

- To separate the obstacles from one another and underline that the learner should not go after solving them simultaneously

- To help the learner understand the limits of perception and prediction. Some obstacles will arise along the way and other will dispersal

- Work toward target condition

- PDCA and the PDCA cycle record template

Coaching Kata

Benefits and limitations

Current and future applications with emphasis on project management

References

- ↑ Rasmussen, L. B., 2011. Facilitating Change – using interactive methods. 1 red. s.l.:Polyteknisk Forlag

- ↑ [https://en.wikipedia.org/wiki/Scientific_method] Wikipedia article on the scientific method

- ↑ [https://en.wikipedia.org/wiki/Training_Within_Industry] Wikipedia article on Training Within Industry

- ↑ [https://books.google.dk/books?id=Po9YAgAAQBAJ]Warren, M., 2010. The Training Within Industry Report 1940-1945, Washington, D.C.: War Manpower Commission Bureau of Training

- ↑ [http://www.kanbanchi.com/what-is-kaizen] An article on Kaizen history and principles from 2015

- ↑ [https://en.wikipedia.org/wiki/Deming_Prize] Wikipedia article on the annual Deming Prize for achievements in quality of production

- ↑ [https://www.amazon.ca/Kaizen-Key-Japans-Competitive-Success/dp/007554332X/ref=sr_1_2?s=books&ie=UTF8&qid=1367970369&sr=1-2&keywords=kaizen+imai] Amazon link to purchase the book "Kaizen: Japanese spirit of improvement"

- ↑ [https://www.kaizen.com/] the Kaizen Institute Consulting Group's official website]

- ↑ [https://en.wikipedia.org/wiki/Toyota_Production_System]Wikipedia article on the Toyota Production System

- ↑ [https://www.amazon.com/Machine-That-Changed-World-Revolutionizing-ebook/dp/B001D1SRRS] Amazon link to purchase the book "The machine that changed the world"

- ↑ [http://www.ncbi.nlm.nih.gov/pmc/articles/PMC3678835/] Teich, S. T. & Faddoul, F. F., 2013. Lean Management—The Journey from Toyota to Healthcare. Rambam Maimonides Med J, 4(2)

- ↑ [http://www.industryweek.com/articles/everybodys_jumping_on_the_lean_bandwagon_but_many_are_being_taken_for_a_ride_15881.aspx] An article called "Everybody's Jumping on the Lean Bandwagon, But Many Are Being Taken for a Ride" stating the challenges in implementing Lean and the results of a survey on how successful are companies in implementing it by Pay, R., 2008. Industry Week - Advancing the Business of Manufacturing

- ↑ [https://www.amazon.com/Toyota-Kata-Managing-Improvement-Adaptiveness/dp/0071635238]Amazon link to purchase the book "Toyota Kata”

- ↑ Example given by Joakim Bjurström, a LSSBB & Cert. TWI Trainer JI during a Toyota Kata training, December 2015

- ↑ [http://www.lean.org/lexicon/kata] Article adapted from Mike Rother 2010 and Shook 2008

- ↑ 16.00 16.01 16.02 16.03 16.04 16.05 16.06 16.07 16.08 16.09 16.10 16.11 [http://www-personal.umich.edu/~mrother/Handbook/Full_IK_Handbook_v32.0.pdf] Improvement Kata Handbook by Mike Rother - a practivcal guide in 552 powepoint slides

- ↑ [https://www.reference.com/business-finance/google-s-vision-statement-66f207e3583fca5f] A Q&A page with the answer on the question "What is Google’s vision statement?"

- ↑ [https://en.wikipedia.org/wiki/Process_capability] Wikipedia article on Process Capability