QUENSH

Contents |

QUENSH

QUENSH (QUality, ENvironment, Safety and Health) systems are an extension of the formal QMS (Quality Management Systems) in the means of health, safety and environmental conformance. The awareness of these issues has been increasingly growing throughout the past couple of decades, making the joint integration of all ISO 9001, ISO 14001 and OHSAS 18001 management systems (also known as QUENSH).

These systems can be set up using Microsoft Word or Excel documentation.

Standards behind QUENSH

A common structure of standards for management systems, drawn up in 2012 and applicable to the new International Organization for Standardization (ISO) standards and future revisions of existing ISO standards. This structure leads to the concept of High Level Structures (HLS), in which certain aspects are met[1]

- Terminology, text, definitions, titles and the common sequence of the same

- Greater importance given the concept of risk

In particular, all management system standards present:

- A structure made up of 10 principal points

- Within each point there are some paragraphs and content, inclusion of which in all the standards is obligatory

- Where necessary, the individual standards may add specific requirements in relation to their fields of application

Furthermore, and a key element of QUENSH, is the health and safety elements which may consist of the Occupational Health and Safety Assessment (OHSAS) series. This standard was adopted as a British standard by the British Standard Institution (BSI) back in 2008.

Management of quality: ISO 9001:2015

The ISO 9000 series are based on seven Quality Management Principles (QMP) ISO. Retrieved 7 June 2017.

These are:

QMP 1: Customer focus

QMP 2: Leadership

QMP 3: Engagement of people

QMP 4: Process approach

QMP 5: Improvement

QMP 6: Evidence-base decision making

QMP 7: Relationship management

The ISO-series are being continually revised by standing technical committees and advisory groups, who receive feedback from those professionals who are implementing the standards. Different versions have been made in 1987, 1994, 2000, 2008 and latest 2015, in which the content is:

Section 1: Scope

Section 2: Normative references

Section 3: Terms and definitions

Section 4: Context of the organization

Section 5: Leadership

Section 6: Planning

Section 7: Support

Section 8: Operation

Section 9: Performance evaluation

Section 10: Improvement

Furthermore, the latest 2015 version is less prescriptive than its predecessors and focuses on performance, which was achieved by combining the process approach with risk-based thinking, and employing the Plan-Do-Check-Act (PDCA) cycle at all levels in the organization. ISO. Retrieved 7 June 2017

Avoidance of environmental risks: ISO 14001

The ISO 14001 standard, which arguably is the most notable standard to the ISO 14000 series, sets out the criteria for an Environmental Management System (EMS). The ISO 14001 standard shares many common traits with its predecessor, ISO 9000. Just like ISO 9000 the ISO 14000 acts both as an internal management tool and as a way of demonstrating a company’s environmental commitment to its stakeholders including customers and clients (Boiral 2007). Boiral, O. (2007). “Corporate Greening Through ISO 14001: A Rational Myth?”. Organization Science. 18: 127. http://pubsonline.informs.org/doi/abs/10.1287/orsc.1060.0224. The standard is meant for to help organization improve resource efficiency, reduce waste and reduce drive down cost. Just like ISO 9001 the ISO 14001 also follows a PDCA cycle. https://en.wikipedia.org/wiki/ISO_14000 Management of safety and health: OHSAS 18001 The OHSAS 18000 series consists of two primary specifications; OHSAS 18001 and 18002, which provides requirements for an Occupational Safety and Health (OHS) management system and implementation guidelines, respectively.

The idea of the OHSAS is to help organizations to:

- Identify and control health and safety risks

- Reduce the potential for accidents

- Aid legal compliance

- Improve overall performance

Normal QMS vs. QUENSH

Historically, many organizations start with the Quality Management System (QMS) ISO 9001, then add the environment management requirements from ISO 14001. Among other changes the OHSAS 18001 was updated back in July 2007 in order to be more easily aligned with the structures of the ISO 9000 and 14000 series. BSIgroup.com. British Standards Institution. Retrieved 8 June 2017. The change also stated greater emphasis on the “health” component of “health and safety”. [BSI Press release July 2017: Health and safety management systems specification OHSAS 18001 is now a British Standard BS OHSAS 18001:2007.]

How companies implement it: The PDCA model can be used by a wide range of organizations - from manufacturing facilities to service industries to government agencies.

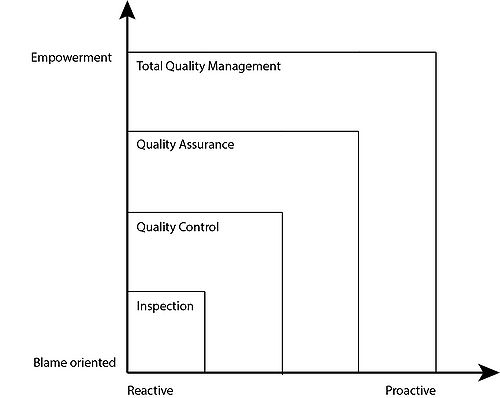

Formal quality management systems (QMS): Inspection Quality control (QC) Quality assurance (QA) Total quality management (TQM)

When it comes to inspection, QC and QA - and as such also QUENSH systems - all share two important limitations. They are all…: - … first-order information loops around static standards (reference to Winch, p.180+329). - … systems that are operationally orientated; meaning that they do not take factors such as customer satisfaction into account. Safety and health: “The Danish/Scandinavian Model” > a lot of influence on the EU standards The Scandinavian model (tri-part system):

EU / government / ministry of employee

The Danish Working Environment Authority The Danish working Environment Council

/ Authority / The social partner

The National Research Centre for the Working Environment 11 Advisory boards - social partners Clinics for Occupational Environment Private advisors and consultants Universities Certification bureau

The reasoning for the 11 boards and other boards are that different parties need different information > The transport part needs other info than e.g. the constructional engineers

Abbreviations

- TQM – Total Quality Management

- QMS – Quality Management Systems

- QA – Quality Assurance

- QC – Quality Control

- PDCA – Plan-Do-Check-Act

References

- ↑ RINA Services: ISO Revision 2015: High Level Structures http://www.rina.org/en/keytopics/iso-9001-and-iso-14001-revision/high-level-structure

Annotated Bibliography

| Author | Title | Date | Category | Chapter | Pages | Brief description | Link |

|---|---|---|---|---|---|---|---|

| Winch, Graham M. | Managing Constructions Projects | 2010 | Book | Chapter 12 | 316-345 | The book is used in university teaching as an introduction on how to manage construction projects. Chapter 12 describes TQM with a focus on contruction | - |

| Wikipedia | Total Quality Management | 2016 | Homepage | - | - | A short introduction to TQM (as it was in the 1980's) | https://en.wikipedia.org/wiki/Total_quality_management |