Lean Construction on Bispebjerg Bakke

The project, Bispebjerg Bakke, is called one of the most amazing building projects in Denmark in recent times because of the complicated design and building components. It was a project where the architecture, the craftsmanship and the use of materials was tested, but because of the use of the management tool Lean Construction, was the building project more efficiently and ended up being cheaper than first expected, even though the standard of the materials was high and there were not compromised[1].

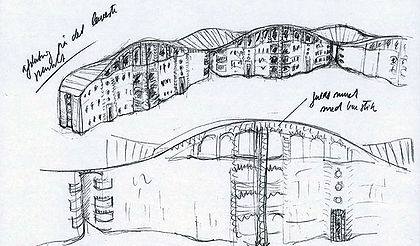

The building is design by Bjørn Nørgaard, a Danish sculptor, which formed the building in clay inspired by music, and then handed it over for the architect firm Boldsen & Holm. They started building in 2004, and was done in 2006, where 135 different apartments spread over 11 houses were ready for relocation. Today the buildings adorn the area around Bispebjerg in the northenwest area of Copenhagen and winds like a big snake through the landscape, to eventually rise from a 4 storey building, up to a 7 store in the end. The idea was to deal with the classic apartments-blocks in the area, and build something spectacular, but keep the design in the traditionally way with red and yellow bricks, too follow the colors of Bispebjerg church and the Hospital.

The challenge for this construction was the curved copper roof and the masonry work because of the curved façades, designed in different forms and colors – yellow on one façade and red on the other facade. No building like this was never built before in Denmark, so the craftsmanship got a big and complicated job[2].

Contents |

Context: Bispebjerg Bakke as en experiment

The ambition with Bispebjerg Bakke was, through the combination of art, architecture and craftsmanship, to build a beautiful and durable housing development, which should be in harmony with the surroundings and the landscape. The idea came at a meeting between the sculptor Bjørn Nørgaard and the President for the Association for Craftsmen in Copenhagen Klaus Bonde Larsen in 1997 – they both had a vision about building with quality materials that last almost forever, combined with the idea of that art should affect the society and that the surroundings – here the building – should have influences on our joy of life[3].. Realea and the Association of Craftsmen supported this idea and agreed to be behind this project.

“Now we are going to build a house, that the industry can’t build.” quote Bjørn Nørgaard[4].

The project ended up consisting of 135 apartments spread over 11 buildings, where the special copper roof combines the buildings. Most of the apartments are built in two or three level to provide a unique and luxury space feeling, and every apartment is without any right angels in the living- and bedrooms, because of the curved facades. Everything is custom-made for this special case, and there is nothing like this anywhere else.

The project became a partnering-case, which enabled the different contractors to contribute each with their competencies at the optimal time in the process to optimize the building in the best given way. It also meant that the contractors were find in the early stages to help realizing the building and make the ‘art sculpture’ to a real home. The project took 2 years to complete, from 2004 to 2006, with a cost of nearly 20.000 kr. peer m2, which is almost twice as much as normal building projects, and involved 28 bricklayers to only the masonry work when it was busiest.

Challenge

The overall challenge with this project was to transform Bjørn Nørgaards sculpture into an actual building with apartments that could be rented out. The transformation of a piece of art of clay into something more tangible and truly because a challenge for both the architects, but later also the craftsmen. Not only should the facades curve through the landscape, but the roof should also curve and in the end rise from 4 floors to 7 floors. This was a big challenge because materials for roofs are all straight, and not even a bit curvy. The challenge was the same with the facades – no fabrics for concrete elements or even masonry bricks make curved elements, and there was no similar building projects in Denmark that could be learned from. This was an outstanding building, and a unique opportunity for contractors to show good craftsmanship with something new and exciting.

Solution

Implementation

References

- ↑ Østergaard, P.H. (2009). Bedre Byggeprocesser. ISBN 978-87-993539-0-3

- ↑ Østergaard, P.H. (2009). Bedre Byggeprocesser. ISBN 978-87-993539-0-3

- ↑ Realdania, link: https://realdania.dk/projekter/bispebjerg-bakke

- ↑ Cain, S. K. (2007). Bispebjerg Bakke - historien om slangen på Bispebjerg.