Omnichannel strategy

> Work in progress <

Contents |

Abstract

Summarise

Introduction

Retailers have traditionally oriented their strategy to deliver the right product at the right location and time. With the rise of internet and smart devices, and the new capabilities of connection and tracking through multiple digital platforms, new challenges appear to last mile logistics, marketing and multi device purchasing. An opportunity arises for retailers to become truly customer-centered and personalize their shopping experiences. However, it adds new challenges and complexities to the supply chain management. Specifically, omnichannel refers to the use of both physical and digital channels combined with the delivery of a seamless shopping experience. This strategy requires a complex robust system and management in which the supply chain must adapt quickly to demand, escalate as required and have a fast response in the last mile delivery. This revolution will mean a transformation in the way that retailers manage their supply chain.

Omnichannel strategy: What it is and how it will model the supply chain

A growing number of customers use multiple channels during their shopping journey. These kinds of shoppers are known as omnishoppers, and they expect a seamless experience across channels [6][7]. Customers prefer retailers who could provide anything, anywhere, at any time and in any way according to customers’ preference [2*] For example, an omnishopper might research the characteristics of a product using a mobile app, compare prices on several websites from their laptop, and, finally, buy the product at a physical store or have it delivered to an address. They could also return it in store or having it delivered. This consumer 3.0 uses recent technology to search for information, offer opinions, explain experiences, make purchases, and talk to the brand. In an omnichannel environment, channels are used seamlessly and interchangeably during the search and purchase process, and it is difficult if not virtually impossible for retailers to control this use (Neslin et al., 2014; Verhoef et al., 2015).

Regarding technology: In the transformation, the adoption of Integrated channels and big data are a prerequisite for competitiveness (D. Grewal et al, 2017) . Advanced analytics allow to track the stock levels and all the data generated in the supply chain, but are also an input for the pricing strategies across channels, and the comparison to competitors. In terms of supply chain, the main changes required include the need for real-time universal inventory, increase in the speed of the decisions and actions and integrated systems to get one view of orders across the supply chain, check the status of any item and be able to fully control the production process. (Case Study: El Corte Inglés Success - “ECI needed to create a single system able to support the functionality desired to provide home delivery for all customer orders, enable new types of cross- channel services and returns, and extend its network of suppliers, ultimately enabling a superior customer experience” )

In terms of project management, it needs to be assured that the whole organization works with one single common set of shared information and objectives, that improve overall transparency of the supply chain. Departments within the organization should not be an impediment to omnichannel strategies: ecommerce and physical departments shouldn’t compete for customers. This implies that some channels might be rewarded for supporting a sale even if it is not through them where is it closed. (Kusum L.Ailawadi, Paul W.Farris, 2017) . The highly competitive market is changing the way companies interact. New forms of collaborations are taking place to compete and integrate the technologies in the main business. One example is the partnership of Walmart and Google presented by its CEO, Marc Lore in August 2017: “Today, we’re announcing an exciting partnership with Google to do just that. Starting in late September, we’ll be working with Google to offer hundreds of thousands of items for voice shopping via Google Assistant – the largest number of items currently offered by a retailer through the platform.”

Omnichannel distribution is in fact the frictionless combination of channels. Consequently, effective and good project management becomes crucial in the implementation of the new strategy, both for the internal to the external management.

PM Tools for retail

The fast pace and complexity of Supply Chain method involved in Omnichannel strategy might be addressed with some of the following tools form Project Management as suggested by Lisa Anderson [1*]. 1. Use the Critical Path Method This well known technique to show in a project schedule the sequence of activities to characterize the most time consuming ones and the relationships between the different tasks could be helpful in this complex and fast paced environment. “Using project management tools to identify and manage the critical path is an effective way to do everything from reminding product groups of upcoming collaborative tasks, to making sure that teams and vendors are focusing on the right activity at the right time, or at least aware of delays that can affect other pressing deadlines.” 2. Communicate and Collaborate “It’s no secret that communication is at the crux of success when managing complexity. For example, a SIOP (sales and inventory operation plan) or a sales and operations planning process can run across supply chain partners, which provide a vehicle to communicate and collaborate on demand-and-supply topics.” “Another way to bridge any communication gaps is to use collaborative project management software. It provides a single source of truth for project and team activity and schedule updates, especially when connection points include global teams working in different time zones.” “Here’s another simple way to approach communication to streamline supply chain complexities: Pick up the phone. If the operations plan or project management platform reveals incoming issues, talk to those task owners who are dependent on you, as well as the people you’re dependent upon.” 3. Use Agile Processes “Agile, a set of fast and flexible processes that accounts for change, helps teams adapt to marketplace opportunities, and improves business performance, lets you to break down complexity into reasonable chunks. Once you try a simple set of circumstances, you add layers of complexity and test again. Thus, it becomes easier to identify issues and manage complexity because you understand what each layer of complexity affects.

“If you lead a team or a project, the more you learn how to successfully manage complexity, the more you’ll thrive. And simplifying complexity is a starting point that will pay big dividends. Also, in today’s Internet-purchasing world, speed is cornerstone. Since managing complexity improves speed and effectiveness, companies that can manage complexity often leapfrog their competition.”

Once reviewed the importance of project management in the industry, the new aspects of it will now have to set the focus on:

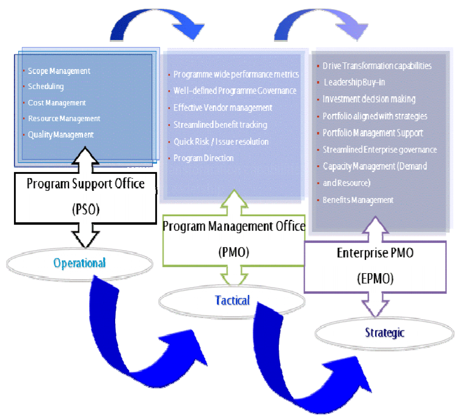

- Owning one source of information, accessible to the whole organization. Information and objectives need to be shared and aligned. A suggested approach for this is the Enterprise Project Management Office (EPMO). While the traditional PMOs focus on doing the things right, include the right way of doing this. The strategic goals are achieved when the teams are supported by this shared business function.

- Accelerate communication with project members and stakeholders. Since decisions must be made faster, the interaction with stakeholders is ought to be continuous.

- Have a quick real-time status overview of all retail projects in one place – anywhere at any time. It becomes more important than ever using a good software that integrates the store data with the online channel, the demand and trends that feeds the marketing decisions, and optimises the operations with the cost and time dimensions. The improvement of the processes in the new circumstances will often result in partnerships with suppliers and other stakeholders. This another dimension of complication that needs to be considered in the new supply chain management.