Lean construction – Principles and application

Contents |

Abstract

The essence of lean project management methodology is to maximize value and minimize waste, preferably eliminate waste. The goal is to achieve as much value to the costumer as possible with as little waste as possible. The lean technique is especially suitable for complex projects and has therefore proven to be an effective for construction project since it was first used in the industry in the mid-1990s.

It is designed to reduce the time, effort and materials required for the project; this is done by reducing waste. Lean construction has 8 different forms of waste: transport, inventory, motion, waiting, overprocessing, overproduction, defects, and human potential. By minimizing these forms of waste, the benefits of lean production will appear. The timeframe of the project will be shortened because of more effective and flexible work. Total cost and increased profit such also be achieved. The lean method is optimal for environmental benefits since the method is formed to minimize excess materials.

To implement lean construction the principles of lean must be considered. These are the basics of lean thinking and are considered in all industries where lean can be utilized. There are 5 principles: defining value, mapping the value stream, creating a flow, establishing a pull, and to pursue perfection.

In lean construction all the parties of a project are considered, from the constructures to the owner. This is to ensure that the right tools and method is being used for all the parts of the project. To optimize productivity and save work hours everybody involved in the project is put at specific task of their specification. This causes companies to stick to project that they are especially suited for and gives them a comparative advantage.

Pioreered by koskela who developed the tfv theory of production in construction.

Background

Lean construction stems from lean production which was developed by Toyota production system during the 1950s. Engineer Ohno in Toyota was committed to minimize waste as a contrast to the craft and mass forms of production. Lean production was developed to save time, money, and materials. In 1992 a seminal report by Lauri Koskela started the adaption of the lean principles to the construction industry. One could say that the adaption is still ongoing today. (AIC) Lean construction does accept the same goal as lean production, but it is specified for the construction market. The main difference is the forms of waste involved. Also, lean construction advocates the view of both product and process development at the same time. The main principles that separate the lean management in construction compared to traditional management is a clear set of objectives for the delivery process, that it is aimed to maximize the performance for the costumer, also at the project level. And that lean applies production control throughout the life of the project, as a result of the simultaneous consideration of product and process development. (Singapore)

Theory

Lean production first developed by Koskela came as a product of an in-depth review of the production paradigms that dominated in the manufacturing industry. There were three competing paradigms: craft, mass, and lean production. By reviewing these paradigms, also including the value management perspective, Koskela came up with the theory which would be the framework of lean construction; the “Transformation-Flow-Value”-theory (TFV). This was a theory implementing the efficacious qualities of the production paradigms transformed into a construction-perspective. The implementation of the TFV concept into construction management allows for the transformation of raw materials into standing structures while at the same time maximizing the flow of materials and value to the costumer. (AIC)

Flow

The flow view in TFV stems from the paradigms mass and lean production. The viewing of production as flow of materials and information led to the principle of waste. The principle of minimizing waste should result in a better workflow and be more sustainable. In lean construction there is defined 8 forms of waste: transport, inventory, motion, waiting, overprocessing, overproduction, defects, and human potential. Minimizing or even better eliminating these wastes is a key aspect of lean construction. By doing so nothing that adds value to a project will be considered and the result is cut of cost and more efficiency. (AIC)

The 8 wastes

- Transport: Transport is a waste in the sense of the expenses and that it does not directly bring value to a project by itself. Therefore, should transport be held to a minimum. Transportation is also bad for the environment which support that it should be held to a minimum.

- Inventory: Excess inventory is a waste when it is not processed. This also transfers to all resources surrounding the excess inventory. This could be storage, capital, transportation etc.

- Motion: Every motion a worker must do to finish a task that is not necessary. This could be everything from having to re-stack items, going to get something, even walking.

- Waiting: Any reason for a worker to be using time by waiting is a waste. This could be due to waiting for the next step of the process, a tool, an item, etc. All time when a worker is not working is time that should be used for the advancement of the project.

- Overprocessing: Overprocessing is when there is taken unnecessary steps to reaching a goal. It could also be ineffective processing; this could be in the form of using bad tools or even making products of a higher quality than what is needed.

- Overproduction: Producing more items than needed is an obvious waste. Items take up storage and accounts for unnecessary transportation of the items. Overproduction is also a waste of the cost of the production which could be used somewhere the money was more needed.

- Defects: The production of defect items is a waste because it forces the production of a repair item, which again is unnecessary use of time and money.

- Human potential: By not listening to all employees and working groups a project could be losing time, ideas, skills, improvements and learning opportunities.

Variability reduction

Related to the principle of waste-removal is variability reduction. The reduction of variability grants for the increase of predictability and reduces cycle times. This makes it easier to do project planning and makes room for less expectancies. Koskela stated that the reduction of variability also increases customer satisfaction and decrease the volume of non-value-adding activities. Examples of variability in the context of construction could be late deliveries, defect tools, wrong design of materials, etc. (Abdelhamid & Everett, 2002) A stunt in the workflow is therefore affected by variability. The methods that can be used to reduce variability are plan buffers, surge piles and flexible capacity. These methods are developed to reduce variability without removing it completely. Today the most used method is plan buffers, which is the concept of always having a backlog of work for all working groups involved. Flexible capacity however is the concept of using resources in more than one way, this can be done by having working groups trained to work with the same resources.

Value

Value is a special component of Koskelas TFV-theory. This part of the theory is all about creation and generation of value. The reason why is special is because this is where the TFV-theory stands out the most compared to other production theories. It makes TFV broader and more robust and is the reason why a production theory can be the framework of a management method in the construction industry. This value-component is not included in lean production which is not necessarily costumer-value driven, as lean construction is. Value is a term that could be difficult to define, it is also a term that have the possibility of changing with time. According to the Lean construction Institute is value generated when costumer capabilities are expanded, creating new needs and purposes, and the facility better fulfills the purposes of customers/producers and demands of other stakeholders. The goal of lean construction is to minimize the difference between a client’s desired value and the value that is realized. This is done by the consideration of the product and the process value management at the same time, this approach is called value-based management. Product value is split into market value and utility value. Process value on the other hand is a unit for the ethical value of the provider. Value generation is perhaps the area of lean construction that is most open for research and improvement.

Lean construction allows projects to avoid mistakes rather than having to fix mistakes.

Substainability

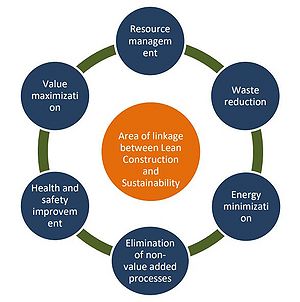

Sustainability has often been brought up when promoting lean construction. Some aspects of lean construction being a more environment-friendly management strategy is more straight forward, such as eliminating waste in form of material and energy minimalization. But also, that lean construction is a more safety-oriented management technique should be considered. Taking care of the health and safety of everyone involved in a project is obviously beneficial for everyone. Resources through potential hospital visits, replacement of workers and broken equipment is saved. In fact, according to Thomassen, crews using lean construction had a 45 percent lower accident rate than crews using traditional construction methods were, this considering that the crews worked for the same company. The advantages of lean implementation in construction in terms of sustainability, which is improved health and safety, waste reduction, and environmental improvement. These advantages are not restricted to the ones listed above. The application of lean yields social and economic benefits as well. Waste reduction, for example, frequently leads to higher productivity and value creation. Improved health and safety will result in a more pleasant working environment, which will benefit society. (Sustainability, UK)

Application

A common misunderstanding of lean construction is that is a way to implement lean production to construction projects. This is not the case and projects that do this will not succeed. This because the already used processes are founded on weak principles and practices. To use lean construction the right way is to use tools and developed processes for the purpose of implementing the lean constructions principles to the project. Lean construction can be implemented in small construction projects as well as in large-scale construction projects. For doing this there are some critical elements that has to be considered, according to Howell (1999) (AIC) these are:

- Clear set of objectives to be established for the delivery process. Customer needs and requirements are well understood.

- Process concurrently, to give more value to the customer needs - this process of parallel design helps positive iteration within the process and negative iteration is reduced.

- Shifting design work along the supply chain to reduce the variation and match the work content.

- Work structuring of the entire process increases value and reduces waste at the project delivery level. Efforts to improve performance at the planning level increases performance at project level.

Last planner system

There are a variety of systems and tools available for delivering lean projects. These lean delivery solutions are comparable in structure and achieve the TFV aims through improving planning, minimizing waste, and including downstream stakeholders earlier in the project process. Examples of such systems are the last planner system and lean development project system but also tool such as visualization, daily huddle meetings, first run studies and 5S is possible to implement. (Further reading) Usually a mixture of these tools are used in construction projects implementing lean construction. In this article the first and most used system, the “Last Planner System” will be presented as a general example of how lean construction is applicated.

In 1992, the Last Planner production control system was established, emphasizing the link between scheduling and production management. This system was the first system suitable for lean construction purposes.

The Last Planner main role is replacing optimistic planning with realistic planning by measuring worker performance based on their ability to consistently meet their obligations. Last Planner's objectives are to remove unnecessary activities by reverse phase scheduling and team planning. The goal is to optimize resources in the long term, as the goal of lean construction. The system have different procedures that uses a pull strategy to create an efficient schedule planning framework that shapes the workflow. It also aligns workflow and capacity, provides work execution methods, and promotes trade communication. (AIC)

The steps of implementation in the last planner system are as follows:

- Master schedule: The master schedule is a timeline for the entire project, complete with milestones. This master schedule is used to create reverse phase scheduling.

- Reverse phase schedules: The reverse Phase Schedule is developed by using a pull technique to make a schedule that works backwards from the completion date. The goal of the phase schedule is to establish a plan for the integration and coordination of numerous specialists' operations, and it serves as a link between work structure and production management.

- Six-week lookahead: This is a tool for having control over the workflow. The essence of the six-week lookahead is to show what work that is going to be completed in the weeks to come. The durations of the lookahead and schedule is calculated from the reverse phase schedule. The lookhead window does not need to be 6 weeks, it could be anywhere from 3-12 weeks. In short, the six-week lookahead planning is the process of reducing uncertainty in order to achieve constraint-free assignments.

- Weekly work plan: The weekly schedule, safety issues, quality issues, material needs, manpower, building methods, backlog of ready work, and any difficulties that may arise in the field are all discussed at the weekly work plan meeting. It encourages two-way communication and team planning in order to exchange project information efficiently and accurately. It can help with safety, quality, job flow, material flow, productivity, and team member relationships.

- Percent plan complete (PPC): Is the relationship between completed tasks and all the task. It's computed by dividing the total number of scheduled activities by the number of activities that are executed as planned. When the slope between two PPC values is positive, it indicates that production planning was accurate. PPC levels are highly variable, ranging from 30% to 70% in the absence of lean implementation. Additional lean building tools, such as first run studies, must be employed to obtain higher values.

- Constraint and variance analysis:

(salem)

Limitations of implementing lean construction

There are some barriers related to lean construction. They can be generalized into 7 categories: managerial, technical, human attitude, the process of LC, educational, government and financial barriers. One of the main barriers is managerial barriers when implementing lean construction. Lean construction is dependent on carefully executed logistics which must go through the top management of the company. Also, the communication between the stakeholders and the different groups in the company must be good. Without these criteria’s a project will suffer from disruption and ineffectiveness.

When it comes to the technical barriers is buildable designs and the certainty of the production process two of the biggest. When a design is not buildable the plans need to be revised, which obviously takes a lot of time and money. Therefore, it is recommended that all stakeholders should be involved form the beginning to make sure that the project is buildable and that the process is feasible.

Human attitude is one of the main barriers of lean construction, this mostly in the physical implementation stage. What is meant by attitude in this setting is the tendency regarding intent, commitment and co-operation that needs to be presented within the stakeholder if lean construction management is going to be implemented successfully. If this drive of wanting the project to be successful by lean principles isn’t there, the project will not succeed.

The process of implementing lean construction is regarded as a barrier. This is because it was found that projects tended to take a long time implementing the management system. There was needed many meetings and discussions. When these meetings also were poorly managed time flew by. This was found to be a problem in the pre-construction phase. If the project managed to implement lean construction successfully the project generated profit and helped the company’s reputation.

Education is regarded as a barrier because it was discovery that the stakeholders involved in a project did not have enough knowledge about the execution of lean construction. The training to be able to understand the principles of the lean way of thinking as well as how to implement it in construction is of course vital. The responsibility of having this training is the top managements.

The last main barrier of lean construction is government and financial barriers. This due to inflation, additional construction cost and poor salaries. Also, the lack of incentives or reward systems and sufficient sources of funding is a barrier for lean construction in particular and construction in general. Provision of contingency cost is a solution to prevent construction projects from inflation or additional cost due to instability of the construction market.

Cultural resistance to change. (Singapore)