FMEA as tool in Project Management

Author: Periklis Aprilis

Contents |

Abstract

In our days, with the constant surge of global competition and the globalization of markets, the success of project implementation and management depends largely on the organization’s business performance. These affairs have brought many changes in terms of economic, technological, and marketing basis. The investment and implementation of new technology require a serious effort from the organization because most of the time deals with factors such as risk, complexity, innovation, and lacking resources. All these factors, among others, can be considered as extremely important challenges from the special workforce of the companies, that’s why it is very common for them to set up and implement new special projects to face them as effective and as quick as possible [1]. [2]

Based on that, identifying and alleviating project risks are very important steps in achieving successful project management and therefore successful projects programs and portfolios. Nevertheless, methods and tools for risk assessment and risk management that have been developed and implemented to increase the possibilities of project success are not yet extensive or easily adopted [3]. However, one of the most well-known and widespread methods is the method called Failure Modes and Effects Analysis (FMEA). FMEA as a Project Management tool allows to:

•Evaluate a process to identify where and how it might fail

•Identify the failure causes

•Assess the relative impact of different failures

•Anticipate potential problems before they occur

On top of that, it is generally accepted that when FMEA is used as a Project Risk Management tool, it can be labeled also as project risk FMEA or RFMEA. So, the RFMEA technique is not just another way of analyzing project risks but helps focus the risk contingency planning, required early in the project on critical risks [3]. Finally, this method is highlighted as crucial in the engineering management community.

Overview of FMEA Method

What is FMEA - Evolution of FMEA

Failure Mode and Effects Analysis can be characterized as an easy to implement and yet powerful pro-active engineering quality method that helps to identify and counter the weak points in the early conception phase of products and processes [4]. In other words, FMEA is a systematic/predictive maintenance method that allows evaluating a process to identify where and how it might fail, identify and ranking the risks associated with various product (or process) failure modes (both existing and potential), prioritizing them for remedial action, acting on the highest-ranked items, re-evaluating those items and returning to the prioritizing step in a constant loop until marginal returns set in[4] [5].

FMEA is trying to anticipate potential problems before they occur, so, from a time perspective, FMEA is essential in the earliest development phases and thus, an early and accurate implementation of the method can be crucial for reducing the corrective actions as well eliminating the cost of a non-compliance identification. The measures that are taken into consideration when FMEA is being implemented is: the probability of failure occurrence (O), the severity of the failure (S), and finally the capacity to detect the failure before it occurs – detection (D) [4]. The multiplication of these measures generates the Risk Priority Number - RPN (RPN = Occurrence * Severity * Detection). The special and professional workforce that will implement the FMEA consists of a multidisciplinary team of people from different educational backgrounds and areas, (design, management, engineering, manufacturing) skilled with specific product/process know-how.

The first application of FMEA dates back to the end of the 1940s when the US Army used it in the aeronautic sector to solve safety and reliability problems in the production and design phases. After this, NASA continued the implementation of FMEA in the early 1960s through the Apollo Program, and some years later, FMEA was adopted by the automotive industry and specifically from Citroen and Peugeot. In 1993 AIAG incorporates FMEA into the QS9000 and since then, this technique is useful for all organizations.

FMEA can be divided into sub-methods throughout the product development phases. For example, DFMEA (Design Failure Mode & Effects Analysis) is used to create new products and analyze product designs before they are released to production. It focuses on potential failures and problems that can be occurred through the design process. On top of that, PFMEA (Process Failure Mode & Effects Analysis) is used to identify and examine risk in-process changes and problems with the function of a product caused by the problem in the process. SFMEA (Software Failure Mode & Effects Analysis) focuses on identifying the causes and consequences of possible software failure modes. Last but not least, RFMEA (Risk Failure Mode & Effects Analysis) focuses on the risk contingency planning required early in the project on critical risks. RFMEA will be analyzed in detail throughout the article.

Why FMEA?

It is generally accepted that FMEA can bring a variety of benefits and positive results to organizations. First of all, it prevents problems and failures in the system, products, or processes before they even occur, reduces greatly the costs, creates a condition for processes durable to unexpected events as well as classifies actions and events based on priorities and seriousness.

Furthermore, FMEA is able to detect possible unidentified failures, find and document the main reasons behind failures and impacts and prepare a response plan with priorities, areas of responsibilities, and frames.

Lastly, assigns the appropriate maintenance actions to uncharted problems and thus, records all the possible work of the maintenance staff.

In conclusion, the main advantages of FMEA can be summarized as:

• Early identification of failures and problems throughout all the stages

• Early improvements in the design and the production processes

• Important cost as well as risk reduction

• Assessing of the failures and their impact as well as finding mitigation solutions

FMEA as a Project Risk Management Tool

The Project Management Institute (PMI) defines a project as a temporary endeavor undertaken to create a unique product, service, or result. The temporary nature of projects indicates that a project has a definite beginning and end. The end is reached when the project’s objectives have been achieved or when the project is terminated because its objectives will not or cannot be met, or when the need for the project no longer exists [6].

As the main goal of a project is to generate an unknown product, it usually involves risk because the steps to achieve the proposed targets are now known by the people who are in charge of the project development. The concept of project risk is related to all the events or conditions that can generate positive or negative effects in at least one project objective. Risks can be classified as internal when the project team can influence or control them, and external when the project team is unable to control and influence them [6].

Effective risk management implementation is an essential element of successful project management. Proper risk management can play a vital role in the mitigation of both known and unanticipated risks on projects of all kinds. Failure to perform effective risk management can cause projects to exceed budget, fall largely behind schedule, miss critical performance targets, or even create a combination of all these drawbacks. So, having an effective method to plan for and manage project risks that are easy for the project team to understand, adapt, test, use and finally apply is very critical. Finally, as projects increase in complexity and size, taking a multidisciplinary approach to project management requires, as it makes sense, proper attention to risk management [3].

A Guide to the Project Management Body of Knowledge PMBOK® Guide 2017, defines the risk management process, as being comprised of six main steps: risk management planning, risk identification, qualitative/quantitative risk analysis (where FMEA and RFMEA belong), risk response planning, and risk monitoring and control [6].

Risk analysis and risk management techniques include expert interviews, expected monetary value, and response matrices, along with more advanced techniques for risk analysis such as Monte – Carlo method. One risk management technique is being implemented by multiplying the probability of the risk occurring with the expected impact of the risk. This method brings as a result the evaluation for each risk. In terms of this environment, the method of using the risk probability multiplied by the risk impact value is moving one step forward and expands by also multiplying a detection value for each risk [3]. As it becomes obvious, by multiplying these three values of the likelihood of occurrence (or probability), severity (or impact), and detection. is like implementing the familiar format of the Failure Mode and Effects Analysis – FMEA. The method of applying the FMEA format to project risk management is defined as mentioned earlier, as risk FMEA or shortly RFMEA. This sub-method of FMEA as an advanced format is capable of capturing project risks in every possible organization in high technology environments.

As stated above, the standard FMEA process evaluates failure modes for occurrence (O), severity (S), and detection (D). The multiplication of these values leads to what is known as the risk priority number (RPN). In using the RFMEA approach, there are a few required modifications in relation to the standard FMEA format. Specifically, the project RFMEA is a tool to identify, quantify and remove or reduce risks in a project environment against the classical product’s aspects as identified in the FMEA. The RFMEA is used in connection with the developed FMEAs for product design, process development, and service deployment [3]. The application and method for both FMEA and RFMEA are analyzed in detail in the next chapter of the article.

Finally, the largest aberration from the standard FMEA approach is the definition used for detection attributes. In the standard method, the highest detection value means that the organization has no detection capability available for the fault/problem, while a low detection number means that the organization has a way to detect the fault before it appears. On the other hand, regarding the RFMEA, the detection techniques are defined as the ability to detect the risk event with enough time to plan for a contingency and act upon the risk. So, if the response team can not be reasonably guaranteed that the risk can be detected either because is very difficult to identify it or because it has subtle symptoms, the detection number has to be assigned as a 10 (value that means that there is no detection method available or known that will provide an alert with enough time to plan for a contingency) at the initial plan [3].

Application & Development

How to use FMEA?

The first and most important task of the FMEA team is to collect information about the project or process that should be fully identified and implementation of activities and processes should carefully be surveyed. On top of that, all potential risks such as environment, equipment, materials, human, etc. should be taken into consideration. To collect accurate, useful, and comprehensive information about the investigated project, the responsible team can get help through interviews or brainstorming sessions with informed, experienced, and skilled people, practitioners, workshop and warehouse employees as well as check documents, operation standards, and requirements of the equipment/workplace [4].

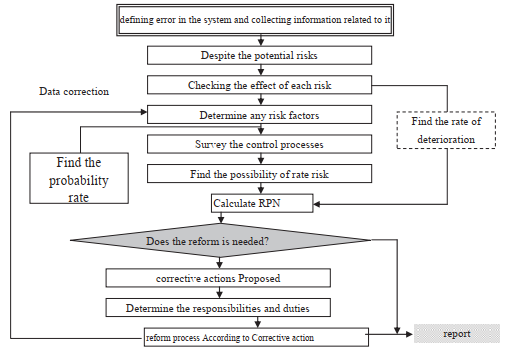

Figure 1 : Implementation phases of FMEA [4].

The process of FMEA consists of 5 different steps:

- Step 1: Define Scope & Topic: In this step a process has to be selected for evaluation. When evaluating with FMEA, works better when the processes have not too many sub-processes. In which case, it would be recommended to divide the process up.

- Step 2: Assemble a multi-disciplinary team of experts. Everyone involved in any part of the process needs to be included. Include operators, customers, and suppliers.

- Step 3: Chart the process, create a detailed flow chart of the current process.

- Step 4: Make HAZARD Analysis (Table 1). Identify each of the potential failures that may occur at each step of the process and classify all failure modes into the risk priority number (RPN). Determine focus areas based on the probability, severity, and occurrence of the failure.

Table 1: Hazard Analysis

| Steps in the Processes | Failure Modes | Failure Causes | Failure Effects | Likelihood of Occurence (1-10) | Likelihood of Detection (1-10) | Severity

(1-10) |

Risk Priority Number (RPN) | Actions to Reduce Occurence of Failure |

|---|---|---|---|---|---|---|---|---|

| 1 | ||||||||

| 2 | ||||||||

| 3 | ||||||||

| n |

- Step 5: Actions and measures. Identify how you can prevent the highest issues from happening. Failure modes with higher RPNs are the ones that should be addressed first. On the other hand, the ones with the lower RPNs will likely not affect the overall process much, so they should be at the bottom of the priority list.

Table 2: Ranking of Severity Indices

| rank (Severity) | Effect |

|---|---|

| 10 | Hazardous |

| 9 | Serious |

| 8 | Extreme |

| 7 | Major |

| 6 | Significant |

| 5 | Moderate |

| 4 | Low |

| 3 | Minor |

| 2 | Very Minor |

| 1 | None |

Table 3: Ranking of Occurence Indices

| rank (Occurence) | Possible Failure Rate | Probability of Failure |

|---|---|---|

| 10 | >1 in 2 | Extremely high: failure almost Inevitable |

| 9 | 1 in 3 | Very High |

| 8 | 1 in 8 | Repeated Failure |

| 7 | 1 in 20 | High |

| 6 | 1 in 80 | Moderately High |

| 5 | 1 in 400 | Moderate |

| 4 | 1 in 2000 | Relatively Low |

| 3 | 1 in 15,000 | Low |

| 2 | 1 in 150,000 | Remote |

| 1 | 1 in 1,500,000 | Nearly Impossible |

Table 4: Ranking of Detection Indices

| rank (Detection) | Description | Definition |

|---|---|---|

| 10 | Absolute Uncertainty | The product is not inspected or the defect caused be failure is not detected. |

| 9 | Very Remote | Product is sampled, inspected and released |

| 8 | Remote | Product is accepted based on no defectives in a sample |

| 7 | Very Low | Product is 100% manually inspected in the process |

| 6 | Low | Product is 100% manually inspected using go/ no-go or other mistake-proofing gages |

| 5 | Moderate | Statistical Process Control (SPC) is used in process and product is inspected off-line |

| 4 | Moderately High | SPC is used and there is immediate reaction to out of control conditions |

| 3 | High | An effective SPC program is in place with process capabilities greater than 1.33 |

| 2 | Very High | Product is 100% automatically inspected |

| 1 | Almost Certain | The defect is obvious or there is 100% automatic inspection with regular calibration or preventive maintenance of the inspection equipment |

RPN value comes from the multiplication of Severity (Table 2) x Occurrence (Table 3) x Detective (Table 4) and can vary between 1 and 1000, so errors and failures will prioritize according to their numbers. Finally, the special FMEA team will re-calculate the RPN number after the changes that will take place, to see the expected improvement. If FMEA used property, it will certainly result in saving money and time for the organizations.

How to use FMEA for Project Risk Management (RFMEA)?

Regarding the Project Risk FMEA (RFMEA), it is developed along the same lines as a typical FMEA. The standard forms of both FMEA and RFMEA are presented in Table 5.

Table 5: Simplified FMEA and RFMEA Forms

| Typical FMEA Coloumns | Typical RFMEA Coloumns |

|---|---|

| Failure ID | Risk ID |

| Failure Mode | Risk Event |

| Occurence | Likelihood |

| Severity | Impact |

| - | Risk Score |

| Detection | Detection |

| RPN | RPN |

The RFMEA is introduced during a team planning, meeting, and utilizing the template form, modified as needed for the specific project. Modifications may include adding project details or applying specific time and money impact values. Concerning the rankings of Likelihood, Impact, and Detection, Detection retains the same rankings as in FMEA and Likelihood has also the same rankings as the Occurrence in FMEA, so Tables 3 and 4 remain the same. Nevertheless, for the RFMEA it will rank Likelihood instead of Occurrence. Thus, about Impact, it has to be created a new table to present the Impact Value Guidelines (Table 6).

Table 6: Rankings of Impact Indices

| Rank (Impact) | Schedule | Cost | Technical |

|---|---|---|---|

| 10-9 | Major Milestone Impact >20% impact to Critical Path | Total project cost increase >20% | The effect on the score renders end item unusable |

| 8-7 | Major milestone impact and 10% – 20% impact to critical path | Total project cost increase of 10% – 20% | The effect on the scope changes the output of the project and it may not be usable to client |

| 6-5 | Impact of 5% – 10% impact to critical path | Total project cost increase of 5% – 10% | The effect on the scope changes the output of the project and it will require client approval |

| 4-3 | Impact of < 5% impact to critical path | Total project cost increase of < 5% | The effect on the scope is minor but requires an approved scope change internally and maybe with the client |

| 2-1 | Impact insignificant | Project cost increase insignificant | Changes are not noticable |

Furthermore, the process of RFMEA consists of 8 different steps [3].

• Step 1: Team brainstorming for risk events. They know that if X happens, then Y will occur, where X=Risk event and Y=Impact of the event happening. The impact might be, serious time delay, an increase in cost, or both. A risk might have multiple impacts, so a risk ID is given for each impact identified.

• Step 2: Assign Likelihood, Impact and Detection Values. The team discusses the scores and agrees on a value that may require additional data from experts or a review of past RFMEAs. The scoring procedure is replicated for the impact and detection factors.

• Step 3: Review RPN Pareto and determine RPN critical value. The analysis of the Pareto is a critical step to determine the value to use. As each project is unique, so are the risks and the corresponding RPN values.

• Step 4: Review Risk Score Pareto and determine Risk Score critical Value. A similar Pareto is generated for the risk scores and a critical value is determined for this measure. The critical values simply guide prioritizing risk response planning.

• Step 5: Create a scatter diagram for RPNs versus risk scores. There is no expectation that the data plotted should fit any pattern.

• Step 6: Determine intersection of Risk Score and RPN critical values. The objective of this step is to find the intersection of the two critical values and to define the initial set of risks that require a response plan to be generated early on. The risk events that have both a risk score and an RPN above the critical values are given priority for initial risk response planning.

• Step 7: Develop Risk Response Plans for Critical Risks. Now, the team must consider risk response strategies such as avoidance, transference, mitigation, and acceptance and document a response plan accordingly.

• Step 8: Re-evaluate Risk Score and RPN based on the actions of the anticipated Response Plan.

After the implementation of the above steps, the RFMEA team has to check the RPN number. If the recalculated RPN does not fall below the critical value, the team must revise the response plan, improve detection methods, or have an approved override to accept the risk. In extreme cases, the risk might be unavoidable and the project might be stopped if the impact is deemed too severe to continue [3].

Benefits of RFMEA

First and foremost, it has to be mentioned that, there have been tangible and intangible benefits realized from the RFMEA method. In terms of tangible benefits, time spent doing up-front risk contingency planning is reduced. Also, the RFMEA gives the team a better method for determining which risk planning can be postponed. That means, the team is having more time to focus on the most critical risks, so the risk response plans are improved. Moreover, the detection value provides another benefit over just using the risk score by aiding the discovery of new detection methods for risk symptoms. Regarding now the intangible benefits, enhanced organizational learning is a critical benefit of RFMEA. Last but not least, if the team can detect a known risk with enough time to plan the contingency at a later date, then this reduces the early planning time and so the team's frustration. This case is true, especially in complicated and challenging project environments [3].

RFMEA is an advanced risk tool that is simple and intuitive. It is based on the standard FMEA technique, modified especially for Project Risk Management. With some minor modifications to a standard FMEA format, the RFMEA provides increased value to the risk management process. RFMEA is based on evaluating both the risk score and the RPN value to detect the critical risks that require immediate risk response planning. In terms of proper utilization, RFMEA can greatly reduce risks on a project, create team ownership in risk planning and act as a resource for future projects in terms of knowledge, lessons, and risk management [1] . [3].

Last but not least, it is worth mentioning that RFMEA has played a vital role in many real-life projects, either big or small in the scale of Project Management. For example, a case study that took place in Jingqiao Development Zone of Shangai in China used RFMEA to analyze the integration of risk management at the start of each construction stage in a large construction project. The results of the case study revealed that RFMEA can be considered as an effective and efficient tool for construction companies [7].

Limitations

For all its benefits in Project Management, FMEA and by extension RFMEA does have a number of limitations. This method has become integral to any production process in any organization. It is widely considered as an improvement over traditional risk analysis and management, which treats each potential failure and problem in isolation. However, it is still not dogmatic. It remains as an assessment tool, not one that is designed to eliminate problems. The best implementation of FMEA can be achieved with the combination of other tools to see the control plans through.

The main limitations of the method can be summarized as the FMEA prioritizes and does not act. Moreover, it is only as good as the professional team behind it, issues behind team members’ knowledge are not likely to be detected or resolved and that contributes to unknowns – unknows results. FMEA is taking on the too-large scope and not getting into the details. Also, is confusing route cause and failure mode and does not customize rating scales. Finally, sometimes it can be characterized as optimism bias regarding the project management.

Annotated Bibliography

• Project Management: A guide to the Project Management Body of Knowledge (PMBOK Guide), 6th Edition, 2017.

This concrete publication has been released as an updated edition to reflect the full range of development approaches and review the latest good practices in Project Management. Each knowledge in this book contains a section entitled Approaches for Agile, Iterative, and Adaptive Environments, describing how these practices integrate into project settings.

• Carbone, T. A., & Tippelt D. D., “Project Risk Management Using the Project Risk FMEA”, Engineering Management Journal, vol. 16, No. 4, December, 2004.

The article proposes the extension of Failure Modes and Effect Analysis (FMEA), to quantify and analyze project risks. The new technique is labeled as the project risk FMEA or RFMEA. The article also explains, how the RFMEA works and how is implemented in project risk management as well as the differences between RFMEA and the standard FMEA technique.

• Bahrami M., Bazzaz D. H., Sajjadi S. M., “Innovations and Improvements in Project Implementation and Management; Using FMEA Technique”, International Conference on Leadership, Technology and Innovation Management, Elsevier Ltd., 2012, DOI: 0.1016/j.sbspro.2012.04.050.

This article, due to innovation in the implementation and management of projects, proposes the effective use of the Failure Modes and Effect Analysis (FMEA) technique. The article introduces the main functions and aims of FMEA, describes the implementation and management of the technique in projects, and finally, uses the FMEA technique in various stages of project implementation, for the improvement of processes and reduction of costs.

References

- ↑ 1.0 1.1 Dos Santos S. R. F., & Cabral S., “FMEA AND PMBOK APPLIED FOR PROJECT RISK MANAGEMENT”, Journal of Information Systems and Technology Management, Vol. 5, No. 2, p. 347-364, 2008, DOI: 10.4301/S1807-1775200800020000

- ↑ Antonioli P. D., Argoud T. T. R. A., Gustavo B., Pires I. R. S., “FMEA as a tool for Managing Risks in ICT Projects, based on the PMBOK”, Asian Journal of Business and Management Sciences, Vol.3, No. 12[01-24], December, 2014.

- ↑ 3.0 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 3.9 Carbone T. A., & Tippelt D. D., “Project Risk Management Using the Project Risk FMEA”, Engineering Management Journal, vol. 16, No. 4, December, 2004.

- ↑ 4.0 4.1 4.2 4.3 4.4 Bahrami M., Bazzaz D. H., Sajjadi S. M., “Innovations and Improvements in Project Implementation and Management; Using FMEA Technique”, International Conference on Leadership, Technology and Innovation Management, Elsevier Ltd., 2012, DOI: 0.1016/j.sbspro.2012.04.050.

- ↑ Dailey, K. W., “The FMEA Pocket Handbook”, DW Publishing Co., Detroit, MI, 2004

- ↑ 6.0 6.1 6.2 Project Management: A guide to the Project Management Body of Knowledge (PMBOK Guide), 6th Edition, 2017.

- ↑ Zeng X. S., Tam M. C., Tam Y. W. V., “Integrating Safety, Environmental and Quality Risks for Project Management Using FMEA Method", Economics of Engineering Decisions, 2010, 21 (1)