Continuous Improvement / Kaizen

Contents |

Abstract

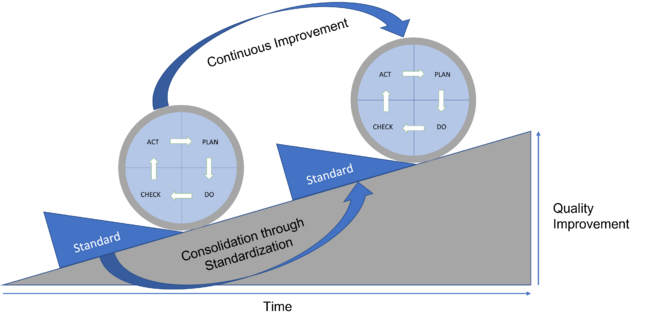

Continuous Improvement, also referred to as Kaizen, is a concept that is related to principles, methods and activities that have the target of continuously improving the performance of an organization or individual. Continuous Improvement focuses on incremental steps that eventually lead to big improvements over time, rather than breakthrough changes. The concept is best depicted by the phrase “a long journey begins with a small step”. In a wider and more cultural sense, the concept is based on the assumption that the world is steadily changing and can always be improved. The concept of Kaizen is Japanese and means kai = change, zen = to improve. Although there are slight definitional differences, continuous improvement and kaizen are fundamentally similar. Hence the two terms are generally used synonymously [1]. In an organizational context, Continuous improvement is a strategic and long-term effort to enhance competitiveness by improving quality, cost and time. The effort usually is directed at achieving certain objectives and is therefore different to the concept of idea management, that revolves around collecting, implementing and rewarding ideas of employees [2]. Improvement is achieved by applying an iterative process of constantly observing the current situation and implementing improvements. Improvements should then be standardized and disseminated to other areas. Furthermore, Continuous Improvement tries to involve employees from all hierarchy levels of an organization in the improvement process. Therefore, it is a popular concept in industry as it is easy and cheap to implement and not limited to any industry and organizational size [1]. The concept of Continuous Improvement is illustrated in figure 1.

Historical of Continuous Improvement

Continuous Improvement first appeared in Japan during the second world war. It was an answer to the numerous and serious damages that the country had suffered. The concept was used by authorities in order to reconstruct the country. Furthermore, the development of continuous improvement was supported by the use of the U.S. training program Training with Industry (TWI Inc.), which aimed at developing training programs for Japanese companies. The small-step approach was preferred, as resources were scarce and major change initiatives could not be afforded. Even though elements of continuous improvement such as suggestion systems or quality systems were regularly used in Japanese industry, the concept only got further attention with the development of the oil crisis in 1973. In a period of financial constraints, companies such as Toyota have used the concept to achieve cost reductions with little expenditure of resources. Parallel the company Canon was able to gain large benefits of up to 200 million US Dollar by launching a continuous improvement campaign. As the profits did not go unnoticed, continuous improvement made its way into the western economy in the 1980s. Remarkable benefits could be achieved by companies such as Xerox, Motorola, Harley Davidson, and General Electrics [1].

Big Idea / Title will be changed

Information about the broader scope of continuous improvement

Benefits and Key ideas

Tools

Tools that are connected to the concept of continuous improvement Root Cause Analysis 5 Why maybe 8D Problem Solving ...

Continous Improvement in Relation to APPPM

Continuous Improvement as an integrated management approach, lessons lernead from projects, capturing of knowledge in the organizational knowledge base, focusing on APPPM in this chapter as the concept itself is explained in a more general view

Application

Workshops

Tasks Forces for Continous Improvement / Teams

Where is it mainly used / Limitation in terms of industry or company size

Limitations

What is necessary in an organization to achieve continuous improvement

Where are the obstacles

Commitment of management

Failure culture

Bibliography

Trabasso, L. G., & Pessoa, M. V. (2016). Continuous Improvement. In Lean Product Design and Development Journey (S. 89-104). Springer International Publishing.

Muralidharan, K. (2015). Continuous Improvement. In Six Sigma for Organizational Excellence (pp. 517-532). Springer India.