New Product Introduction (NPI)

The new product introduction (NPI) plays an important role in business growth since it is a process of idea transformation from R&D stage into a launch product. As a first mover to adopt a new product into the market, it will improve profit and key competitor of the business. Yet, one professor at Harvard Business School alarmingly suggests that 30,000 new products hit the market each year, but as many as 95% fail. This is a real cause for concern for businesses because more than a quarter of their revenue and profits are generated from the launch of new product [1].

The NPI processes requires a dedicated project manager to ensure that the team is communicating effectively so the design, prototyping, engineering and manufacturing stages go as smoothly as possible [1]. It is highly encouraged to develop the NPI plan in the beginning stage, the more efficient process will be. The process covers varies aspects which will bring the benefit to the organisation. The cost reduction in development stage can be avoid due late design changes, such as the material sourcing and other valuable resources on unnecessary prototypes. The NPI process also incorporates tools targeted at ensuring the product meets customer need and the process is capable of producing quality products.

This article discussed the NPI methodology including the different phases to implement NPI and the optimization for framework design of new product introduction management. The implication for the NPI process including the need of better understanding of inter-functional coordination are discussed.

Contents |

Big Idea

What is NPI?

The NPI process (New Product Introduction) is an idea carries out process through various structed phased and result in a finished product being launched to the marketplace. The product could be something tangible, as in the case of a new model automobile, or intangible as in a particular service offered . NPI program involves a large great of collaboration in organization as well as cross-functional communication lead to be successful. This process is driven and managed by a cross-functional team that keeps a check on every aspect of the project. The different phases are controlled by approval gates which ensure the project has met specific criteria before moving onto the next phase in the process [2].

Although NPI process required a dedicated project manager to conduct and coordinate between different functions, however it is more elaborate than a to-do list. The process is carefully managed by a team of expert including representatives from different department (for example financial, procurement, engineering and marketing) and stakeholders.

Why NPI is important?

Visibility to product performance has never been higher, while competitive pressures continue to squeeze margins and time to market. To compete, manufacturers must deliver better, faster and cheaper [1]. A new product that is brought to a rapidly changing market on time but 50% over budget cuts profits only by 4% over the first five years. Yet, coming out six months late but within the development it will earn 33% less profit [3].

The implementation of NPI has become imperative for small and medium size business following the industry leader that have realized the importance of NPI. The well-defined NPI process will create robust and successful products. Another obvious reason that NPI should be involved in the beginning step of development is to keep teams in constant communication and ensure everyone is hitting their deadlines. However, there are other benefits from those who have already implemented it have realized as following:

- Improve product quality: The NPI process incorporates tools focused on ensuring the best practices of design, engineering and testing, which help assure the best quality of products. This helps to maintain consistent new product quality.

- Reduce manufacturing cost: By incorporating the Voice of Customer (VOC) into the early stages of the project, the design team can avoid late design changes, multiple revisions and repeated costly validation testing.

- Fast time to market: Reduced new product development period mean that the product will take a shorter time to reach the right customers and start to generate revenues. There are several critical factors that affect the manufacturing time such as design errors, material issues, manufacturing defects and more. During the NPI process, all of these factors take into account which helps improve the time to market capabilities.

- Improve production efficiencies: Throughout the NPI process, the team will employ the good practice of DFM/DFA (Design Manufacturing and Assembly) which will help streamline manufacturing process efficiently.

NPD & NPD

The acronyms NPI (New Product Introduction) and NPD (New Product Development) are used interchangeably by many organizations. In some cases, NPI activities begin after design and development and merely deal with the product production launch and marketing [1]. The New product development (NPD) is the foundation for NPI which is the process of idea developing to bring a new product to the marketplace. NPD phases required the input from various stage from engineering throughout supply chain partner whereas the NPI process focus on the product from the viewpoint of manufacturing. NPD process transform a market opportunity into a marketable new product to satisfy customer requirements.

Application

Phase-Gate Reviews

A Phase-gate or waterfall process is technique commonly use in project management. The phase-gate process is ideal for projects that involve large teams across multiple departments, as it is designed to handle many spinning plates in a short amount of time. It is typically used for new product developments, software/app/website launches and business-wide changes [4].

The NPI operates often using gate-phase model as it is the systematic model to manage a new product start to end. The number of phases and gates depend on the project/initiative size and a phase has only one gate associated [5]. Each of phases ends in a gate review where the project manager asked to present the pre-defined deliverables and demonstrates the outcomes to the management whether the project should move on to the next phase of the product development process. Each of these reviews ends in a go/no-go decision [6]. Therefore, there are opportunities for management to exterminate the project before committing to its launch.

New Product Introduction Steps

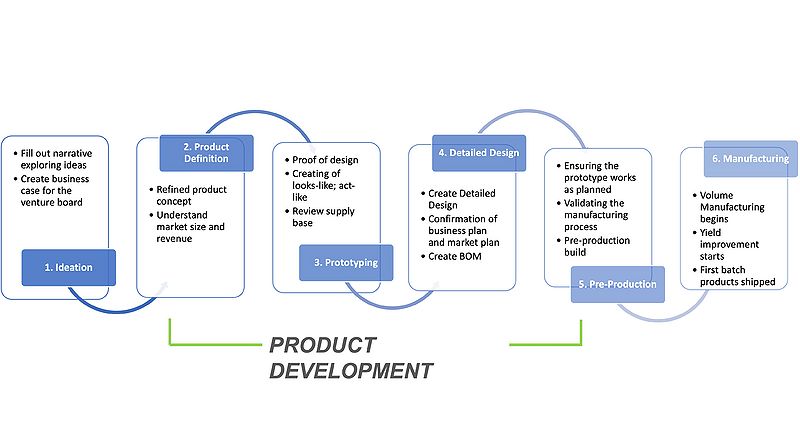

The NPI comprises all the activities concerned with a new product development right from the conceptualization to launch and implementation phase. The steps involved in this process may vary from project to project, however the goals are the same: reduce waste, avoid miscommunication, speed up production and save money. It can be easily broken into the six steps with five gates:

- Step 1: Ideation

- Ideation is the initiation of idea that has been generated. It is considered an the most important step where most of new product ideas come from. The idea could be developed from the exploring, market research and business analysis.

- Step 2: Product Definition

- The product definition often called discovery step as it is a process to explore the customer’s needs. In this step, the product requirements and concept are defined along with the voice of customers (VOC). The associate tool that often uses in this step in the Quality Function Deployment (QFD) which convert the product requirements to design specification. After the specification are integrated into one or more concepts, it should be review by the project team. A project charter develops containing following information:

- Project Budget

- Project Scopes

- Project Objectives

- Key Deliverables and Dates

- Identify Stakeholders

- Step 3: Prototyping

- The prototyping step involves the investment for developing the product. A detailed business plan is created with an intensive market research in parallel that proving the product feasibility. This is considered as the last phase of idea development where the idea will be finalized before starting to develop to the product. This is a crucial step as it reduces the market risk for the new product in all businesses. As it involves the investment, the financial model for the product is created and the price also determined in this step.

- Step 4: Detailed Design

- The activities in this step focus on the product design and carried out some early simple test of the product. In most cases the test performs with the customer to getting their feedback and incorporating it into the prototype. DFM/A (Design for Manufacture and Assembly) are performed in this step in order to finalize the design as well as BOM (Bill of Material) also generated. This is a stage where the procurement team will get involve heavily. Below are some of the common outputs during the detailed design steps.

- 3D Models of the design

- Bill of Materials (BOM)

- Design Failure Mode and Effects Analysis (DFMEA)

- Manufacturing preliminary footprint

- Preliminary engineering design

- During the gate review, the project manager should cover the project information including the design, project timeline, risk assessment, business plan and financial status. Marketing, sales and production plans are also developed in this step as it is important that the goal of the project reflect in the plans.

- Step 5: Pre-Production (Validation/Testing)

- At this stage the product analysis and testing are performed to ensure that the prototype works as planned. The testing covers the product function, the manufacturing process, customer approval and the financial model for the products. PFMEA (Process Failure Modes and Effects Analysis) is a qualitative tool that can be used to identify the potential failure mode. The process risk is being to analyze and addressed.

- As it is a last step before the final product is ready to be launch, the management requires to approve whether the project should be moving forward to the next step or the prototype need to be revised. Likewise, the market strategy needs to be confirmed at this point. The common outputs in this stage are:

- Process Flow

- Process Failure Mode and Effects Analysis (PFMEA)

- Process Work Instruction (for prototype)

- Fixture or Tooling creation and build

- Prototype Builds

- Step 6: Manufacturing

- The pilot launch of the product is set up and the first production is performed in this step. The manufacturing processes are refined and validated through pilot builds and capability studies [1]. As well as the documentation process including the production control plan, quality control and process work instruction are being developed and implemented. This is a step where the team required to bring the final product to the market including marketing and sales plans. During this step, there are many on-going activities following examples:

- Process Work Instruction and Standard Work

- Training

- Production Control Plans

- Process Capability Studies

- First Article Inspection (FAI) for Pilot Build

- Development of Manuals

Limitations

A successful product performance and quality at initial release bring a lot of benefit and business growth in long term. Aspirational growth targets are fundamental to future business strategy and it greatly involves the exploring of new opportunities and introduce new products into the business.

Product quality, product performance, cost/margin and time to market are the successful criteria of NPI. These seems are the same criteria as general manufacturing process however, an excellent initial product release will reduce the risk of re-engineer the product. Since every gate that was assessed in NPI steps has been determine thoroughly on the engineering points therefore, it would be easy to manufacture on a small or large scale. Similar to the quality aspect, the process involves multi people assessing in each stage which is likely that the quality problem will be able to be addressed and analyzed in design steps. The output can be result in DFMEA (Design Failure Mode and Effect Analysis) and PFMEA (Process Failure Modes and Effects Analysis).

As mentioned earlier up to 95% of new products fail to introduce to the market, this is due to a common high risk and the areas involve multiple stakeholders, risk, product verification and validation. Therefore, the challenges of NPI are vary by discipline. Three common issues cause to the failure of NPI are: lack of consistent or formal processes, disparate systems and data sources, and late engagement in NPI which are directly impact to the key NPI success criteria.

Apply Lean Thinking to NPI

The origins of Lean are in the Toyota Production System (TPS) pioneered by the late Toyota Chief Engineer Taiichi Ohno (Ohno 1978, 1988, Monden 1983, 1993) and sensei Shigeo Shingo (Shingo 1989) [7]. They started developing the ideas in the late 1940s and early 1950s, and by the early 1960s they had fully worked out the principles of lean production (Womack et al. 1990) [1]. Toyota aims to complete their product on very low budget, with this reason it leads to leaner operations which help to expose further waste and quality problems in the system. Thus the systematic attack on waste is also a systematic assault on the factors underlying poor quality and fundamental management problems (Monden 1993) [1]. There are seven commonly wastes in the TPS: over- production, waiting, transportation, inappropriate processing,

The goal of lean is to eliminate waste – the non-value added component in any process and inefficiency in manufacturing operations. The process became so successful that it has been embraced in manufacturing sectors around the world. By applying the lean principle, it can create huge improvements in efficiency, cycle time, productivity, material costs, and scrap, leading to lower costs and improved competitiveness. Lean principles are not a strategy however it is much more powerful enabler when applied effectively [8].

According to the Karlsson and Ahlstrom (1996) [1], their observation of a company over 2.5 years and found out that the principle of lean product are involved the following elements:

- Supplier involvement

- Cross-function teams

- Simultaneous engineering

- A focus on integration of activities instead of co-ordination

- Strategic management

- Black box engineering

Based on the observation, they state that a successful lean product development requires approaching these interrelated techniques as elements of a coherent whole rather than implementing some of the techniques.

Following The Machine that Changed the World, Womack and Jones (1997) [1] develop a comprehensive Lean philosophy, based on the five principles, that could be applied to the entire enterprise not just to manufacturing.

- Specify value

The value should be defined precisely from the idea initiation phase. Covering the perspective of the end customer in term of a specific product with specific capabilities offered at a specific price and time. Similarly to the beginning step of NPI process, the output of processes are in the form of data, information or knowledge, as opposed to material in manufacturing. To develop the detailed characteristics of an NPI process that is world class at ‘specifying value’, the needs of both internal and external customers were analysed by the researcher [1]. The characteristics of an NPI process that satisfies the specify value principle are the following:

- - Identify the right customer, market and product

- - Identify the customer needs in term of performance, quality price, timing, desirability, and options

- - Deliver the right information at the right time, and at targeted cost to downstream processes/customers

- Identify the value stream and eliminate waste

By analyzing the value stream of current NPI that delivers the specified value, will eliminate non-value adding processes and activities. The process or value stream management can be defined as the process of ‘Defining, analyzing documenting, controlling and improving. An NPI process that identifies the ‘value stream and eliminates wastes’ have characteristics as following:

- - It has processes in place that enable identification of the value streams (both current and future)

- - Its value streams (processes and activities) are clearly defined, mapped, standar- dized and measurable

- - Milestones are achieved with minimum possible waste, and non-value adding activities, and within budget (cost)

- Make the value flow

Information is an important element in NPI activities. The inefficacy information handling will create delay in process which will impact the delivery target in consequence. In order to implement the principle of flow, an organization should be able to control information flow. As well as add information value as activities progress from one to the next and eliminate non-value added information. An NPI process that enables the ‘flow’ of value have the features or characteristics as following:

- - A process and organiza- tion structure that focuses on improving integration of NPI functions as opposed to just co-ordination

- - Effective program planning and control

- - No excessive batching or buffering of information

- - Effective communication and data flow of multifunctional information

- - Effective flow of technology into Projects

- Let the customer pull (value) process

A program plan in which activities, workload and objectives are based on customer needs or downstream activities are the key that program manager should have in control. An effective information should be available and accessible as and when desired.

- - Activities are driven by a stage-gate reviewed program plan (including resource plan, communication plan, work breakdown structures, and organi- zation breakdown structure) based on the needs of down- stream processes and customer

- - Suppliers are responsible for developing com- plete modules, with detailed specifications. The company focuses on product functional- ity rather than detailed guidelines and specific measurements and features. (Black box engineering)

- Pursue perfection

Continually identify ways to eliminate wastes and non-value adding are the important ability that should be considered.

- - Has a process and organizational infrastructure dedicated to lean transformation and leadership that enables continuous review and improvement of NPI value streams, products, and services

- - Uses tools and techniques that enable continuous sustainable improvement

According to the UK LAI (Lean Aerospace Initiative) research activity, the wasted within NPI process was carried out. The investigation was performed based on the application of seven TPS wastes which adapted with the area of NPI processes. The workshop performed with 60 participants including engineers and non-engineering function and extensive literature reviews. The research result identity as waste category which would enabler a better-managed and targeted waste elimination process. The wastes in NPI process are shown in the table below:

| Waste Category | Types |

|---|---|

| Over production |

|

| Defective Information |

|

| Organizational wastes Wrong organization structure |

|

| Lack of resources |

|

| Inappropriate supply chain processes |

|

| Defective Activities (Defective Product) |

|

| Waiting |

|

| Unnecessary Transfer of Information |

|

Annotated Bibliography

- Maximizing New Product Introduction Success by Matt Wuensch, Market Development Manager, Valor Divisionof mentor graphics corporation

- This paper discusses the key success of NPI process including two keys criteria: ‘First Time Right’ and Design data flow.

- Apply Lean Thinking to New Product Introduction by Badr Haque & Mike James-moore

- This paper discusses the lean thinking and its principles as prescribed by Womack and Jones which have been successfully applied to manufacturing and operation environments. The paper associates with case studies and research literature have been published extensively.

- Redefining the new product introduction process by Donald Gerwin and Paul Guild

- This paper discusses attempts to reorganize the NPI process occurring in the information technology industries. The project discussed involve change in the roles of the design and manufacturing function in both upstream and downstream phases.

Reference

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 https://www.redlinegroup.com/insights/the-best-practices-for-new-product-introduction-npi-in-manufacturing-97314115541

- ↑ https://qualityinspection.org/npi-new-product-introduction-process-benefits-podcast/

- ↑ Nevens T.M., Summe GL and Uttal. B (1990) ‘Commercializing technology: What the best companies do’. Harvard Business Review. May-June. pp. 154-163

- ↑ https://www.projectmanager.com/blog/phase-gate-process

- ↑ http://thepmjournal.com/welcome-npi-in-product-management-processes/

- ↑ https://www.tcgen.com/new-product-introduction/#modern

- ↑ Shingo, S., 1989, A Study of the Toyota Production System from an Industrial Engineering Viewpoint (Cambridge, MA: Productivity Press)

- ↑ Apply Lean Thinking to New Product Introduction by Badr Haque & Mike James-moore