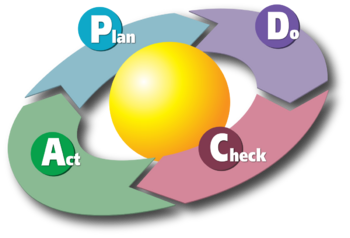

PDCA cycle

"It [The PDCA cycle] is a flow diagram for learning and for improvement of a product or of a process." [1] W. Edwards Deming

The PDCA (Plan-Do-Check-Act) cycle, also known as the Deming cycle or the Shewhart cycle, is a project management method used to continuously improve the quality of a process or a product. This cycle is based on the four following phases: Plan, Do, Check, and Act.[2]

- In the Plan phase, the problem to tackle is identified, and an action plan is set up.

- In the Do phase, the plan is put into action by the project team.

- In the Check phase, the differences between the results and the expectations are evaluated.

- In the Act phase, corrective actions are taken in order to improve the evaluated situation.

By breaking down a complex problem into these four phases, the organization obtains a clear overview of the situation and is forced to systematically identify areas of improvement, take actions about it, compare the results and the expectations, and make the necessary adjustments.

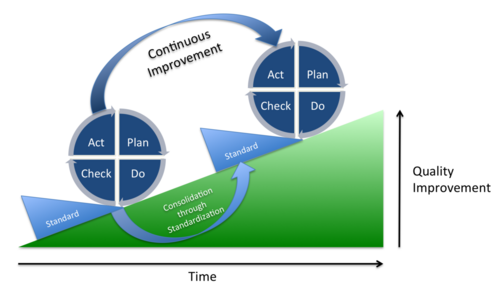

The PDCA cycle is an iterative method, which means that at the end of the fourth phase, it is recommended to implement again the method on the new situation to continue the improvement of the product or the process. This iterative approach results in an increase of efficiency and effectiveness inside the organization.

Developed by Eric Vincent Vong

Contents |

Presentation of the method

The PDCA method has four phases, each leading to the other, and aims to establish a virtuous circle to improve the quality of a product or a process. [3]

Plan

It is the most important phase in project management because objectives must be defined before acting. Usually, this phase is carried out in three stages.

- Identify the problem to solve, using for example the five W’s or brainstorming.

- Understand the causes, using for instance the fishbone diagram.

- Look for solutions and define an action plan.

Do

It is the moment where the action plan is implemented. Examples of action plan can be creating a prototype, carrying out tests, writing a software code, … In this phase, each team inside the project team works on its side, according to the action plan.

One point to mention and to be careful on is that even if each team works on its side, it is essential to have regular meetings with the whole project team to avoid the tunnel effect and to keep a global overview of the progress of the tasks, because some tasks can impact another one.

Check

In this phase, the project team makes sure that the solution that has been developed (in the Do phase) to tackle the problem (identified in the Plan phase) works well. The easiest way to do that is to compare the results with the expectations in terms of key performance indicators.

Of course, this analysis will emphasize differences. But it is understandable, and it is essential to keep these differences in mind for the next phase.

Act

This phase is usually carried out in two stages:

- First, corrective actions are taken in order to minimize the differences between results and expectations identified in the Check phase.

- Then, the project team draws conclusions of the whole four phases and uses it to begin again the PDCA cycle, by capitalizing on the knowledge acquired.

Visual representation

The most important idea to remember about the PDCA cycle is that each iteration must lead towards a better situation, a better quality of the product or the process. To remember this idea, the PDCA method can be represented with a block behind the wheel, which prevents it from going back and which symbolizes the capitalization of the knowledge.

Examples

Toyota

Ningbo Women and Children’s Hospital

Variation of the method

PDSA

OPDCA

DMAIC (from the Six Sigma)

Pros and cons

Pros

Cons

References

- ↑ W. Edwards Deming, "The New Economics for Industry, Government, Education", 1993

- ↑ Nancy R. Tague, "The quality toolbox, Second Edition", 2005

- ↑ Rémi Bachelet, "L’essentiel des outils d’organisation de projet", Ecole Centrale de Lille, 2019