Circular Economy in Project Management

Abstract

In recent years sustainability and waste reduction have been some of the main focuses in manufacturing industries. This is due to the need of decreasing current environmental impacts and securing minimal future impacts. In terms, project management is being considered sustainable if it achieves long-terms benefits [1]. This can be problematic for large-scale companies, as they are more difficult to change structurally. However, the long-term benefits can be achieved using Circular Economy. Circular Economy is a method used to mitigate the environmental impacts by using materials much more efficiently [2].

Circular Economy is an approach that works alongside the corporate strategy and business development, which is used in project and portfolio management to reduce waste by introducing new methods of reusing, refurbishing, repairing, recycling, leasing, and sharing existing resources that prolongs the products life cycle [3]. This gives the company opportunities to reinvent their products so that they can create circular systems that makes it possible for already sold products to be part of a new product. For that reason, Circular Economy should be a crucial part of project and portfolio management both in regard to the design and planning of new products, but also in the assessment of existing products.

Implementing Circular Economy may both reduce waste, but also improve finance, as fewer raw materials may be needed. This benefit is ideal for competitiveness and securing more reliable sources of acquiring raw material needed for new products.

Contents |

Circular Economy Definition

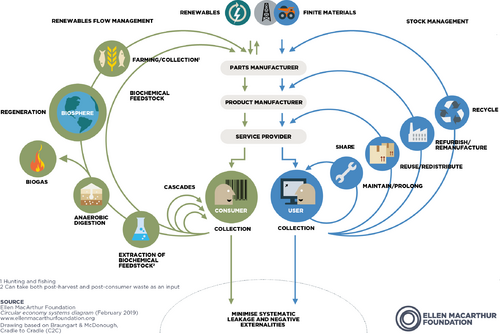

Circular Economy is an approach that moves away from the linear system of producing and consuming, and instead goes towards a circular system of reuse. Linear systems are the most common to use, as the company do not have to make any logistics in getting the materials back. However, this results in the materials going lost after the use of the consumer.

With a circular system instead it is possible to make use of the already mined materials to produce products that gives value to the customer.

What is a Circular Economy?

Generally we can differentiate Circular Economy in two systems, one being the biological cycle and the other being the technical cycle. This differentiation is important due to the types of circular system that could be implemented. In the biological cycle we engage with the consumer, whereas the technical cycle we engage with the user. A biological cycle consists of products such as food, chemicals or biological products that are not possible to become a new product by its own. However, they can become soil and be used as a biological material for the production of new products. A techical cycle consists of products that are made of extracted materials and do not biodegrade. This could be electronics, plastics, and everyday products. The materials in the technical cycle are those that are most attractive to recover, as they most often are valuable to the producers. The biocentric cycle products are however also valuable in another sense. Essentially we have broken the cycle of products regenerating as soil, so with the focus of putting materials back to earth, we can ensure a sustainability. One of the key challenges that we currently are facing is that we mix the biological products with the technical products, which makes the biodegradability useless. This is for instance the case with textiles.

Due to this differentiation it is important to analyse the products in a companies portfolio in order to identify what their products include and which type of cycle is implementable.

When looking at the options of circular systems, there are in each cycle many different options. These options are on different levels and are more expensive the close we get to the origin. This is due to the labor an manufacturing costs being added to the processes. Directly linked to the technical cycle we have the following options [4]:

- Leasing

- Leasing is the option for a user to use something without owning it.

- Leasing makes it possible to aware something for a brief period of time.

- Leasing could increase the amount of users, as some might not have the finance to own the product, but can instead rent it.

- Sharing

- Sharing is the collaboration between users the increase the usage of a product and thereby maximising the utilisation and life span of the product.

- Sharing is mainly focusing on the consumption phase rather than the manufacturing.

- Sharing makes it possible for companies to make money on fewer produced products.

- Repairing/Prolong

- Repairing is the process of fixing minor issues in order to prolong a products life cycle.

- Repairing is the cheapest option for manufacturers to resell already sold products.

- Having repaired products could open up second hand markets, which could increase profits.

- Reusing/Redistribute

- Reusing is the option of reusing a material or component in a new product. This could be products containing high-quality material.

- Examples of these products could be electronics that contains components that lasts for many years, which makes them ideal in the production of newer products.

- Redistributing is similar the reusing, but instead it focuses on going to a new market with the products.

- This could be driftshops for used clothing, used autoparts, etc.

- Reusing is the option of reusing a material or component in a new product. This could be products containing high-quality material.

- Refurbishing/Remanufacturing

- Refurbishing is the option of remanufacturing the component.

- Refurbishing is more expensive than reusing, as more manufacturing processes are needed. However, the process will ensure a much more similar result as a new product.

- It is primarily done when a component or product cannot remain the in circulation in its current state. For that reason it is re-engineered to have the same specifications as a newly manufactured one.

- Recycling

- With this process the raw-material is treated and reused for the production of a new component.

- Everything is broken down until the basic materials, which then can be used to produce newly manufactured ones.

- This proces is most demanding as you have to go through all manufacturing processes again to produce the product.

It could be easy to think that it would make sense to directly recycle. However, having a finished product is of most value. That is due to the product having the original costs of manufacturing as a value. If we would to recycle, then we would strip apart the product and be left with "raw materials". These are of less worth than materials that have been processed. For that reason, it is critical to analyse the products in the portfolio and create a project management that ensure that the value of the products are as high as possible.

Why is Circular Economy important?

Creating a circular system, is very costly, both due to the labor and ressource cost of setting up the system, but also all logistics and data needed for the system to work most effective. So why would you invest in such a system, if it is that expensive?

Well essentially there a many great advantages of creating a circular system. With circular systems it is possible for the company to reach new market opportunities. This may result in attracting new types of customers, which will broaden the already existing market, which will increase profits. Other than the economic advantages, there will be many environmental benefits. You may reduce environmental pressure and stimulate innovations in eco-designs. This will help the brand of the company, which may attract more customers and make the company more competitive.

Circular Economy Implementation

Implementing Circular Economy can be a difficult process, especially if you have limited resources. However, there are some general guidelines of how to approach the subject. We can make the strategy of implementation as a 3 step plan:[5]

- Create Plans and Goals

- Provide Knowledge to educate your staff

- Innovate, Select and Engage

Create Plans and Goals

Provide Knowledge to educate your staff

Innovate, Select and Engage

How to analyse your portfolio for possible circularity

Circular Economy Limitations

Difficulties companies could face when implementing Circular Economy

References

- ↑ Circular Economy in Project Management, Prosense Consulting, https://www.prosense-consulting.com/en/sustainable-project-management-brings-circular-economy-to-life/

- ↑ What is a Circular Economy?, United States Environmental Protection Agency, https://www.epa.gov/recyclingstrategy/what-circular-economy

- ↑ Circular Economy Introduction, Ellen MacArthur Foundation, https://ellenmacarthurfoundation.org/topics/circular-economy-introduction/overview

- ↑ The Technical Cycle, Circular Innovation Lab, https://www.circularinnovationlab.com/post/the-circular-economy-basics-series-the-technical-cycle

- ↑ 3 ways of implementing Circular Economy, Impacx, https://impacx.io/blog/circular-economy-business/

Other key materials:

1. Portfolio Management: The standard for portfolio management, 4th Edition (2018)

2. Portfolio Management: ISO 21504 (2015 Edition)