Circular Economy in Project Management

In recent years sustainability and waste reduction have been some of the main focuses in the application of new projects, programs and portfolios (PPP) in manufacturing industries. This is due to the need of decreasing current environmental impact and securing minimal future impacts, as PPP management is mainly being considered sustainable if it achieves long-terms benefits [1]. This can be problematic for large-scale companies, as they are more difficult to change structurally. Nonetheless, long-term benefits can be achieved through the application of circular economy, a method that reduces environmental impact by utilizing materials more efficiently [2]. Circular economy works alongside the corporate strategy and business development, enabling PPP management to reduce waste by introducing new methods of reusing, refurbishing, repairing, recycling, leasing, and sharing existing resources that prolongs the products life cycle [3]. For that reason, there are many positive applications of circular economy for PPP managers, as they can incorporate it in both the design of new projects or to reinvent their current products to make them part of circular systems. For a PPP manager to utilize circular economy there are many decisions needed to be considered in implementing it. However, as with all other systems, there are limitations to circular systems such as the energy needed for new systems to be implemented.

Contents |

Circular economy definition

Circular economy is an approach that moves away from the linear system of producing and consuming, and instead goes towards a circular system of reuse and recycling [3]. Linear systems are the most common to use, as they do not have to make any logistics in getting the materials back. This will simplify a program or project for a PPP manager, as it is more expensive and troublesome with setting up more complex manufacturing systems. However, this results in the materials going lost after the use of the consumer, which keeps the need of new virgin materials. With a circular system it is instead possible to reuse the materials that are already consumed and are in the system, which creates many opportunities to make money and end the overconsumption and extraction of new material. This supports portfolio management, as one of the key principles in portfolio management is to ensure the strategic objectives are fulfilled, which is important due to organizations often undergo strategy redefinition as a result of pressure for greater profitability, changing market conditions, balancing the needs for change with the needs of ongoing operations, and so forth [5]. Circular economy can help accomplish these things as it creates new market opportunities, whilst still aligning with the corporate strategies.

Biological cycle and Technical cycle

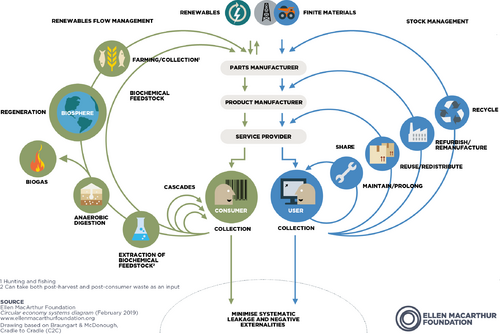

Circular economy is the process of reintroducing products back into the system to limit the need of new virgin materials. This system can be differentiated in two categories: the biological cycle and the technical cycle. This differentiation is important due to the types of circular system that can be implemented in a project or portfolio. In the biological cycle the system engages with the consumer, whereas the technical cycle engages with the user. The biological cycle consists of products such as food, chemicals or biological products that cannot become a new product by its own. However, they can become soil and be used as a biological material for the production of new products. The techical cycle consists of products that are made of extracted materials and do not biodegrade. This could be electronics, plastics, and everyday products. The materials in the technical cycle are those that are most attractive to recover, as they most often are very valuable, due to the price of acquiring new materials. However, the biocentric cycle products are likewise valuable in another sense. Essentially we have broken the cycle of bio-products regenerating as soil, as we no longer focus on returning materials in the ground. For that reason to ensure sustainability, it is important to try and find methods of doing so. In the investigation of products, one of the key challenges for some PPP managers is the mix of biological products with technical products, which makes the biodegradability useless. This is for instance the case with textiles. This problem decreases the ability to recycle and decreases the sustainability of manufactures. Due to this differentiation it is important to analyse the products in a portfolio in order to identify what the products include and which type of cycle is implementable. Having this overview makes it easier to understand how to move towards a greener profile and a system that makes better use of reusing and recycling. One way of doing so is having a focus on the Portfolio Life Cycle, which is a method of processes used to collect, identify, categorize, evaluate, select, prioritize, balance, authorize, and review components within the project portfolio to ensure that they are performing compared to the key indicators and the strategic plan [6] [7].

As depicted in the butterfly diagram from the Ellen MacArthur Foundation, there are many different options of circularity in each cycle. These options are on different levels and become more expensive the more complex they are, due to the addition of labor and manufacturing costs added to the processes. The technical cycle offers the following options of circularity, which are described in the table that identify the different circular systems and the benefits of using them [8]:

| Types of circularity | |

|---|---|

| Definition | Explanation |

| Leasing | Leasing is the option for a user to use something without owning it. This is ideal for customers who do not need the product for a long period of time.

Leasing could increase the amount of users, as some might not have the finances to own the product, but can instead rent it. |

| Sharing | Sharing is the collaboration between users. By sharing products the usage of the products increases and thereby maximising the utilisation and life span of the product. This also makes it possible for companies to make money on fewer produced products.

Sharing is mainly focusing on the consumption phase rather than the manufacturing. |

| Repairing

Prolong |

Repairing is the process of fixing minor issues in order to prolong a products life cycle. It is the cheapest option for manufacturers to resell already sold products.

Having repaired products could open up second hand markets, which could increase profits. |

| Reusing

Redistribute |

Reusing is the option of reusing a material or component in a new product. This could be products containing high-quality material. Examples of these products could be electronics that contains components that lasts for many years, which makes them ideal in the production of newer products.

Redistributing is similar to reusing, but instead it focuses on going to a new market with the products. This could be driftshops for used clothing, used autoparts, etc. |

| Refurbishing

Remanufacturing |

Refurbishing is the option of remanufacturing the component. It is primarily done when a component or product cannot remain in the circulation in its current state. For that reason it is re-engineered to have the same specifications as a newly manufactured one.

Refurbishing is more expensive than reusing, as more manufacturing processes are needed. However, the process will ensure a much more similar result as a new product. |

| Recycling | With this process the raw-material is treated and reused for the production of a new component. Everything is broken down until only the basic materials remains, which then can be used to produce newly manufactured ones.

This proces is most demanding as you have to go through all manufacturing processes again to produce the product. |

Which type of option to use?

There is a common misconception that direct recycling is always the most optimal solution with circular economy. However, having a finished product is of most value. That is due to the product having the original costs of manufacturing as a value. If we would to recycle, then we would strip apart the product and be left with the raw materials, which in most cases are of less worth than materials that have been processed. Therefore, it is critical for a PPP manger to analyse the products in the portfolio and create strategies that maximises the value of the products. Additionally, it is important for PPP managers to realise the capabilities of their company or project and to know if you have the possibilities to implement complex systems. If they do not, then other methods of securing these capabilities could be through co-operations and contracts with other companies who have the expertise to recycle or reuse. Working with other companies could reduce the problematics for the company as they do not have to reinvent their processes and integrate new systems.

To summarise the process of adapting to a circular system, then a PPP manager must first identify if their products belong to the biological cycle or the technical cycle. Then they need to asses which type of circular system that is most optimal in regard to their type of product. For that reason, it is critical for a PPP manager to have a comprehensive understanding of their products and capabilities as a company.

Why is circular economy important?

Implementing a circular system is very costly, as it requires substantial investments in labor, resources, logistics, and data to ensure its effectiveness. So why would you invest in such a system, if it is that expensive?

Despite the high cost of implementing a circular system, then there a many advantages making it a great investment. One of the main advantages is the possibility for the company to reach new market opportunities. By offering a broader range of product services and refurbished products, companies can attract customers with limited resources and thereby increase profits. Other than the economic advantages, there are also significant environmental benefits. By reducing environmental pressure and promoting innovation in eco-designs, it is possible to improve the brand of the company, which may attract more customers and make the company more competitive.

In summary, although a circular system is expensive, it provides both economic and environmental benefits by introducing more options to the customer and helps integrate a society that relies less on consumption and more on innovation.

Circular economy implementation in PPP

Implementing circular economy can be a difficult process, especially if a manager have limited resources. However, there are some general guidelines of how to approach the subject. These guidelines are very simplified, as all projects are different, which highlights the importance of the PPP manager knowing which type of products and project they are working with. Knowing which type of project a PPP manager works with, then the MSP framework [10] can be used to implement circular systems, as it gives a PPP managers clear overview of the different elements when doing a project [11]. The framework should be used by analysing each circle mowing from outwards and inwards. The requirements in each circle should be fulfilled in order to reach the inner circle.

As the framework can be comprehensive to use, the strategy of implementation can be set as a 3 step plan: [12]

- Create plans and goals

- Provide knowledge to educate your staff

- Innovate, Select and Engage

Create plans and goals

Strategic planning is crucial when a company undergoes structural changes, such as adopting circular economy. To develop an effective implementation plan, project managers may consider the following questions:

- What is it you are trying to achieve with a circular system?

- Which type of circular system do you want?

- How will the logistics work?

- How will you change the internal manufacturing processes to support the system?

- How will the implementation affect the company financially?

- What are the risks of implementing the system?

- Who will be in charge of the implementation?

Answering these questions should help the PPP manager to reflect on the method of approach for achieving the desired outcome of the transition to circular economy. In the project process it is recommended to include smaller milestones, which makes it easier to monitor the progress over time and identify any potential issues or problems. To analyze the changes it is helpful to make use of the PDCA: Plan, Do, Check, Act. This is a contentious process of improving, and in a circular system, there will always be something to improve.

Provide knowledge to educate your staff

As in every project the employees affected by the changes needs to be involved and understand how and why the changes are happening. To do so, it is important that some key personal of the management team are in charge of the implementation process and educate the staff properly in the changes. In this process it is important to understand what type of employee you are dealing with and how to approach them. Personality tools can be used, such as the Nine Enneagram Types.

Having all employees on board and sharing knowledge between departments helps decrease the risks of failure and helps improve the process as more inputs for success will be included.

It is important to start the education of the staff in the beginning of the project.

Innovating, selection and engagement

When establishing a circular economy, it is important that it supports the business strategy. There are three pillars of circular economy for business purposes: Innovation, Selection, and Engagement. [12]

- Innovating is essential in a circular system, as it can improve both the product development process and also the organisational structure. Innovation enables a company to keep evolving and motivate its employees, leading to increased productivity. Without innovation the productivity will decline and it will impact market share, revenue and customer satisfaction. For that reason innovation is an important factor in circular systems.

- Selection is the process choosing how and what can be part of a circular system. The products and resources in the company needs to be assessed in order to understand how they can be incorporated in a circular system. In the selection process it is also important for the company to evaluate which capabilities they have and the complexity of a system they can implement. Some questions that needs to be answered are:

- How will logistics work?

- How will the internal processes look like?

- Which departments needs to be involved?

- What is the cost?

- Engagement is a critical process for getting all relevant stakeholders and processes included in the implementation of the circular system. Everyone needs to be on board and understand what their responsibilities are. To engage stakeholders many different tools can be used, such as surveys and workshops. A clear vision is important for a successful engagement.

Difficulties companies could face when implementing circular economy

In the implementation of the circular economy, one of the primary issues and barriers is the lack of awareness, which is necessary before initiating the planning of strategies and processes [13]. For that reason, it is important for the people responsible for the implementation of the circular economy to start by making all the correct assessments and analysis of the current state of the company, before attempting to implement any changes.

Circular economy is not a familiar concept to many companies, making it challenging to impart an understanding of the process. These barriers can be overcome, but that requires for the planning and education of the staff to be well executed. Overlooking any aspect of a major change such as a circular system will lead to flaws of the system and potential failure.

Circular economy limitations

No system is perfect, not even a circular system. One of the main concerns with circular economy are rebound effects. [14]

- Rebound effects: The implementation of a circular system involves the introduction of multiple processes into the existing system. Furthermore, in order for a business to grow, consumption must grow. These new processes all require energy, due to the laws of thermodynamics. This means that even processes trying to reduce the waste of resources needs to consume other resources to do so. This will create environmental impacts, as there will be an increase of emissions. For that reason, it is important to conduct a comparative analysis of the current system and the proposed circular system. If the drawbacks of the circular system outweigh its benefits, it may not be feasible to invest in.

Final remarks

The transition to a circular economy represents a significant challenge for companies seeking to adopt more sustainable management practices. To successfully implement this transition, a PPP manager must gain a comprehensive understanding of the company's current state and portfolio. Despite these challenges, the adoption of circular systems presents several opportunities for managers to enter new markets, increase profitability, and minimize waste. By replacing linear systems with circular systems, the status quo of consumption and manufacturing can be improved significantly.

Annotated bibliography

- Ellen MacArthur Foundation. Circular Economy Introduction. Organization

- The Ellen MacArthur Foundation is an organization dedicated to implementing circular economy and promoting the positive benefits. They create evidence-based original research and work with businesses, international institutions, governments, cities, universities, non-governmental organisations, innovators, and many others to learn and understand the opportunities. They have created the well know Butterfly Diagram, which is popular to use in understanding circular systems. Their websites includes much information to better understand circular economy, including a video of two members who describe the butterfly diagram and the application of it.

- Circular Innovation Lab. The Technical Cycle. Organization

- Circular Innovation Lab is a danish think tank that is trying to transition the world into based on more circular economy. They collaborate with governments, agencies and international organizations trying to create more circular solutions. They mainly focus on four areas, those being textiles, electronics, food, and plastics. The reference was used to understand the technical cycle and the biological cycle, which are the core foundation of the butterfly diagram developed by the Ellen MacArthur Foundation.

- Project Management Institute Inc.. Standard for Portfolio Management (4th edition) and Standard for Project Management (7th edition)

- The books present two aspects of management, those being the portfolio and project management. The books were use to get more insight to how PPP managers have to react in regard to project and structural changes. With circular economy the companies have to make drastic changes to the logistics whilst sill aligning with the companies purpose. From the books it was acknowledged the methods a manager can make use of in order to analyse their products. Additionally, the books describe the differences between project and portfolio management, which was used to understand how circular economy fits within their scopes.

References

- ↑ Circular economy in Project Management, Prosense Consulting, https://www.prosense-consulting.com/en/sustainable-project-management-brings-circular-economy-to-life/

- ↑ What is a circular economy?, United States Environmental Protection Agency, https://www.epa.gov/recyclingstrategy/what-circular-economy

- ↑ 3.0 3.1 Circular economy Introduction, Ellen MacArthur Foundation, https://ellenmacarthurfoundation.org/topics/circular-economy-introduction/overview

- ↑ Butterfly Diagram, Ellen MacArthur Foundation, https://ellenmacarthurfoundation.org/circular-economy-diagram

- ↑ Standard for Portfolio Management (4th edition) Chapter 1.8.1, Project Management Institute Inc., https://app-knovel-com.proxy.findit.cvt.dk/web/view/khtml/show.v/rcid:kpSPME0033/cid:kt012S0XL2/viewerType:khtml/root_slug:standard-portfolio-management/url_slug:title-page?&b-toc-cid=kpSPME0033&b-toc-root-slug=standard-portfolio-management&b-toc-title=Standard%20for%20Portfolio%20Management%20%284th%20Edition%29&b-toc-url-slug=introduction&kpromoter=federation&view=collapsed&zoom=1&page=1

- ↑ Project portfolio management techniques, Project Management Institute, Inc., https://www.pmi.org/learning/library/project-portfolio-management-techniques-7624

- ↑ Standard for Portfolio Management (4th edition) Chapter 1.8.2, Project Management Institute Inc., https://app-knovel-com.proxy.findit.cvt.dk/web/view/khtml/show.v/rcid:kpSPME0033/cid:kt012S0XL2/viewerType:khtml/root_slug:standard-portfolio-management/url_slug:title-page?&b-toc-cid=kpSPME0033&b-toc-root-slug=standard-portfolio-management&b-toc-title=Standard%20for%20Portfolio%20Management%20%284th%20Edition%29&b-toc-url-slug=introduction&kpromoter=federation&view=collapsed&zoom=1&page=1

- ↑ The Technical Cycle, Circular Innovation Lab, https://www.circularinnovationlab.com/post/the-circular-economy-basics-series-the-technical-cycle

- ↑ MSP (5th edition), O'Reilley, https://www.oreilly.com/library/view/managing-successful-programmes/9780113316786/bm01.xhtml

- ↑ Management of Portfolios Chapter 2.4.1, OGC, https://ebookcentral.proquest.com/lib/dtudk/reader.action?docID=4462746&ppg=1

- ↑ MSP Framework, O'Reilley, https://www.oreilly.com/library/view/managing-successful-programmes/9780113316786/chap07.xhtml

- ↑ 12.0 12.1 3 ways of implementing Circular Economy, Impacx, https://impacx.io/blog/circular-economy-business/

- ↑ Applicability and Limitations of Change Management for Circular Economy in Manufacturing Companies, Niclas-Alexander Mauss, Dominik Bühner, Johannes Fottner, https://reader.elsevier.com/reader/sd/pii/S1877050922023766?token=B3873F9B40A3CA286032A7D07C2020AE044EB37A1AB555C37F4BDB5F8E4AF25C5D4DFCB1D37D5C38115001EF4ADEAB56&originRegion=eu-west-1&originCreation=20230505145325

- ↑ Circular Economy Disadvantages, Jouni Korhonen, Antero Honkasalo, Jyri Seppälä, https://www.sciencedirect.com/science/article/pii/S0921800916300325

Key materials used through the wiki:

- Project Management. The standard for project management, 7th Edition (2021)

- Portfolio Management: The standard for portfolio management, 4th Edition (2018)

- Portfolio Management: Management of Portfolios (2011 Edition)