Work Break Down Structure(WBS)

"Developed by Qian Xiao“

Contents |

Abstract

Work break down structure is a project management tool that breaking down complex project into phases, deliverables and work packages. A WBS can integrate scope, cost and deliverables into a single tool and provides the necessary framework for detailed cost estimating and control along with providing guidance for schedule development and control. The following article aims to provide an overview of the basic concepts of WBS, the preparation of creating a WBS, and discussing the three different use cases with WBS, finally analysis the limitations of using WBS.

Introductions of WBS

Work break down structure (WBS) is defined as: "Deliverable oriented hierarchical decomposition of the work to be executed by the project time to accomplish the project objectives and create the required deliverables.” by the Project Management Institute (PMI). For project, it is one of the most important project management tools that integrates scope, cost and schedule baselines ensuring that project plans are in alignment. And the project can be planned, executed, controlled, monitored, and reported effectively with this tool.

Elements of WBS

Work break down structure is made up of three elements, which are work, breakdown and structure.

- Work: tasks that can produce tangible results;

- Breakdown: a hierarchical structure of progressive subdivision and classification;

- Structure: organization of the sections according to a certain pattern.

Types of WBS

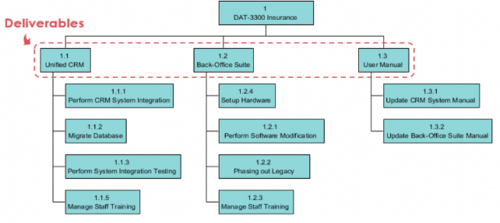

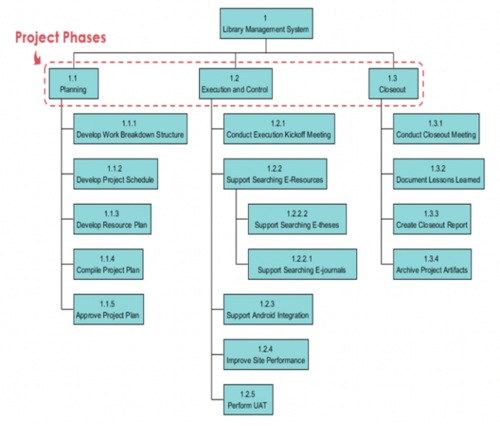

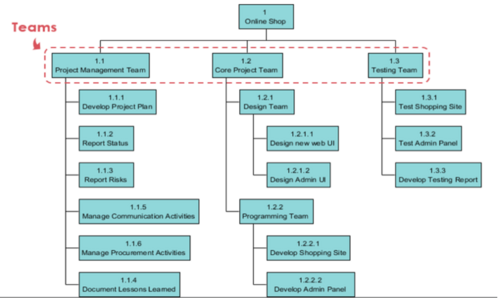

Here are three main types of WBS: 1) Deliverable-Based, 2) Phase-Based and 3) Responsibility-Based. And the main difference between the two approaches are the elements identified in the first level of WBS.

- A deliverable-based work breakdown structure clearly demonstrates the relationship between the project deliverables (i.e., products, services, or results) and the scope (i.e., work to be executed). From figure 1(a), the level 1 elements are summary deliverable descriptions, while level 2 elements in each leg of the WBS are all the unique deliverables required to create the respective level 1 deliverable.

- A phase-based WBS clearly demonstrates the process of a project. From figure 1 (b), each element of level 1 is typical phases of a project, while the level 2 elements are the unique deliverables in each phase. This kind of WBS type requires work associated with multiple elements be divided into the work unique to each level 1 element.

- A responsibility- based WBS clearly defines project activities based on the organization units that will work on the project. This structure allows the responsibilities involved in the project management process to be assigned to each member.

Features of WBS

The WBS represents a specific description of the project deliverables and scope. It is not a statement of how or when the deliverables will be produced, but rather a refinement and description of the project outputs and scope. It has the following features:

- Supporting the definition of all work required to achieve outputs, objectives, deliverables, or specific outcomes.

- The hierarchical structure used to describe and define the deliverables, and which is established in a “parent-child” relationship.

- Having an objective or specific result, which is known as a deliverable or output.

Importance of WBS

In the execution of the project, there will be found a variety of problems that will lead to disadvantageous impacts on the project target. Many factors lead to several project stumbling blocks, such as over budget, delayed projects, poor quality, and rework. These problems affect the project objectives of cost, quality, and time of project[1]. A constructed WBS can result in the following outcomes:

- Clear work assignments, goals, objectives, and deliverables.

- Scope can be fixed and manageable.

- Budget can be under control.

- Deadline can be meet.

Preparation methods of creating a WBS

When creating a WBS, here are several methods that can be used for creating a WBS. These included outlines and organization charts, fishbone, and brainstorming techniques, top-down and bottom-up development strategies. And WBS templates are available and corporate guidelines or standards can be referenced or copied for quick-starting WBS development[2]

It should be based on the specific project aim, requirements, assumptions, and constraints to choose an appropriate method. The following table highlights some advantages and disadvantages of the above-mentioned methods.

| WBS creation method | Advantages | Challenges |

| Top-down |

|

|

| Bottom up |

|

|

| WBS standards |

|

|

| WBS template |

|

|

When developing the WBS, the project management team first needs to decide which development method to use. The choice of a top-down or bottom-up approach is to some extent a personal choice and may depend on the habits and mindset of the project team, as well as organizational practices. In addition to these considerations, some guidelines and explanations as to which approach may be more appropriate.

Top-down: Use a top-down approach in these situations

Project managers and project management teams have little to no experience in developing WBS. Top-down development allows for a step-by-step understanding and elaboration of the WBS.

The nature of the project's product or service is not well understood. When the scope and nature of the project is not clear, a top-down approach to developing the WBS with all stakeholders helps to gain understanding and consensus. The nature of the project lifecycle is unfamiliar or not well understood. Top-down development of the WBS is more likely to identify lifecycle issues and characteristics. There is no appropriate WBS template available. When developing a WBS "from the ground up", it is much easier to start with the overall project deliverables, such as building a bicycle, and then iterate to identify sub-elements.

Bottom-up: A bottom-up approach is used in these situations

The nature of the project's product or service is well understood. For example, if the organization has developed a very similar product or service in a previous project, the project team may already have a very good understanding of all the interim deliverables required for the new project. The nature of the project lifecycle is well known, and if the organization always uses the same project lifecycle, then the interim deliverables for that lifecycle are well known and can be used to begin bottom-up WBS development. There are appropriate WBS templates. If the organization has WBSs from similar product or service projects and these WBSs can be reused, then the bottom-up approach is the same.

WBS standards and templates

In general, if WBS standards or WBS templates are available, they should be used. There are many samples WBSs in the literature, but care must be taken when choosing to use a sample WBS as a template. Organizations can have WBS templates for very similar projects and are highly encouraged to use these templates. However, if the project is very different from other projects in the organization and no template seems applicable, then develop the WBS "from scratch" using a top-down approach. Regardless of the method chosen to prepare the WBS, the resulting WBS must have all the core characteristics of a high-quality WBS. the WBS must describe 100% of the project's work, must be oriented toward deliverables rather than activities, and must be hierarchically arranged.

Application of WBS

The WBS in the project management

The process of project management with WBS

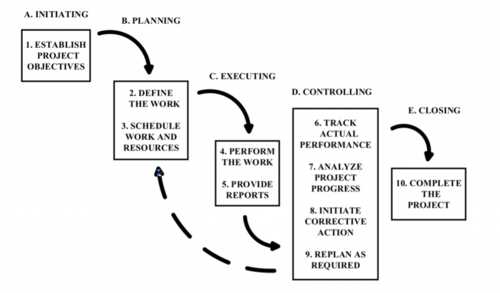

Project management is a continue process. It focuses on achieving the project objectives within the project management triad of performance, constraints and goals[2]. Here are five types of activities included in the project management process: initiation, planning, execution, controlling and closing (see figure 3.1). This illustration emphasizes the importance of planning before extensive project work and the importance of bringing the project to closure once all the work done.

The WBS is a critical element in the planning and execution of a successful project. Many projects cost, schedule, and quality failures can be traced directly to flaws in the development of the project’s WBS. It is highly unlikely that a project will be successful without the existence of a quality WBS. In contrast, developing and applying a quality WBS will significantly increase the likelihood of successful project completion.

| Process | Importance of WBS in process |

| Initiating |

Historical WBS elements can contribute in determining the scope and viability of projects. |

| Planning |

|

| Executing |

|

| Controlling |

|

The WBS and PFMEA in closed loop management

The concept of PFMEA

Failure models and effects analysis (PFMEA) is an effective model for ensuring a high reliability[5].. It is used for analyzing potential failure modes and their effects, finding the corresponding root causes, and providing measures to prevent failures in the life cycle of a product. PFMEA is a systematical management method used to improve the process reliability[4].

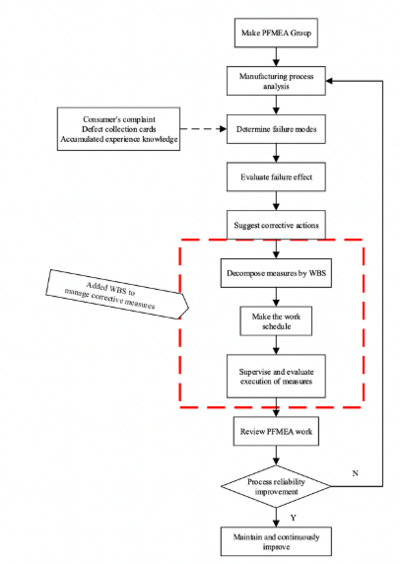

PFMEA combined with WBS

To actualize PFMEA management scientifically, normatively, systematically, and effectively, it is necessary to decompose the PFMEA project. And to guarantee the effectiveness of measures by decomposing work. Into smaller specific tasks, work breakdown structure and PFMEA are combined.

Purpose of the combination

The purpose of this combination is to decompose the improvement measures into work units or work packages. It is convenient for management and supervision. What is more, another purpose is reflecting the technical relation, organisational relation, resource relation and workflow.

Process of the combination in closed loop management

The general PFMEA worksheet included the following elements: Function, Failure mode, Cause, Effect, Detection, Occurrence, Severity, RPN threshold, Action.

The combination of PFMEA and WBS is the process of breaking down the preventive and control measures proposed in the PFMEA into top-down and bottom-up components for measure management purposes, using tools such as the WBS. Each improvement measure proposed in PFMEA table for a failure mode can be regarded as a project.

Apply WBS to decompose it into work units, in turn allocate to the corresponding departments. Lebel these distribution results to form a work schedule finally. Monitor the implementation of measures to ensure that the measures are carried out based on the work schedule[4].

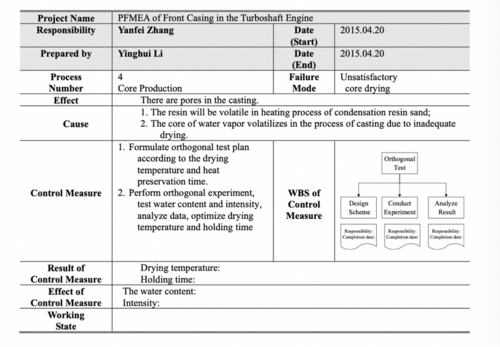

Take a core production of turboshaft engine as an example to illustrate the application in the manufacture process and quality control of the methods combined WBS with in PFMEA. The steps are as following:

- Organizing a special PFMEA work team to take charge the whole work. The group leader was responsible for determining and coordinating the PFMEA projects, directors in charge of determining working steps and formulating corrective actions to the problems in the product manufacturing process, other personnel also took part in the implementation of the project.

- The team discussed the process of the core production and fill the result in the table 2.

- The team invited related experts to review previous PFMEA work.

- Persons in charge took actions in accordance with WBS of control measures to improve the process reliability.

- The measures was taken effectively and the process reliability was indeed improved[4].

Seen from the figure 3.3, it is an example for a core production. This method can be meet the practical manufacturing process need better.

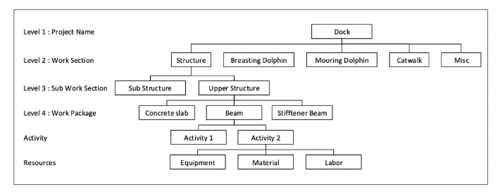

The WBS on a port construction project under risk

The port project can be divided into 9 elements: preliminaries, dock, trestle, dredging, causeway, container yard, facility buildings, mechanical electrical, and breakwater, all of these can be considered as main project and became WBS level 1.

Then the level 1 will be divided into work package, and the work package will be divided into activities and resources.

Identification of risk to the port construction project that may affect cost performance derived from literature studies, and the risk score can be calculated by:

R=P*I

Where R=Risk Factor, P=Probability and I=Impact.

And based on the survey of respondents, there are several risk events:

- High sea waves

- Material usage exceeds the required volume

- Qualifying labor is not according to plan

- Error of equipment productivity estimates

- Error calculate the volume of work

- Underwater conditions differ from the assumption of tenders

- Error predicting weather and events

- The price of material purchased exceeds estimates in planning

- Procurement of labor for implementation is not in accordance with needs

- Tides occur[7]

Engineering project risk identification is a particularly complex process, and using general risk identification methods to identify risk factors that exist during the implementation of engineering projects would be costly in terms of manpower and time, and would affect the balance of risk management benefits and costs.

The WBS decomposition method, as an important method in engineering project management, is commonly used in engineering project management. A project using the WBS decomposition method will have a complete project flow chart, schedule, cost plan and personnel plan, which will provide sufficient information for project risk identification.

Limitations of WBS

Despite having so many benefits of a work breakdown structure, there are a few cons that come with the work breakdown structure. Keep reading this section to find out what are the possibilities and how we can find a solution for them. After all, it is not a large and comprehensive breakdown structure covering the entire project, and many key project information cannot be fully represented in the WBS. Since we mainly present the "deliverables" of the project, our actual implementation is often trapped in detail, and we do not put it into the project to systematically view its relationship. It is far less used than project activities and progress documents, which are often shelved and reduced to work memos. Here are some uninventable limitations of WBS.

The orientation may be changed

The structure of the work breakdown can be the result of a directional rather than a prescriptive approach. Approaches may change, but program outcomes will not. Deliverables or planned results must never be tightly coupled with other methods and actions.

The details may be wrong

It is hard to find the best and most accurate level of details when it comes to WBS. Since you must fit just one on the page, it will become extremely difficult to find what exactly the tasks are and what must be the creation of them added to the WBS.This may lead to the creation of useless and vague tasks under which you will have a list of non-similar tasks.

Annotated Bibliography

Project Management Institute. “A Guide to the Project Management Body of Knowledge (PMBOK® Guide)”- Sixth Edition, 2017 The PMBOK Guide is the guide to Body Of Knowledge within Project management, providing widely accepted standards and guide in the use of them. It covers most aspects within project management, although PMI, the publisher, realizes that no book can contain the whole Body of knowledge. This comes clear when the reader looks for motivation in a team, or goal setting techniques. Still, the PMBOK recognizes the importance of both.

References

- ↑ "J T Amin et al 2020 IOP Conf. Ser.: Mater. Sci. Eng. 930 012006."

- ↑ "Qiang Maoshan, Chen Ping, Project Management Institute. Work Breakdown Structure (WBS) Implementation Standard [M]. Electronic Industry Press, 2008."

- https://www.workbreakdownstructure.com

- Haugan G T. Effective work breakdown structures[M]. Berrett-Koehler Publishers, 2001. https://www.bkconnection.com/books/title/Effective-Work-Breakdown-Structures

- J T Amin et al 2020 IOP Conf. Ser.: Mater. Sci. Eng. 930 012006.

- J. Xue and M. Huang, "Closed loop management of PFMEA combined with WBS," 2016 Chinese Control and Decision Conference (CCDC), Yinchuan, China, 2016, pp. 4003-4008.

- Z.G. Liu, F. Q. Li. Process FMEA Applied Research, Quality and Reliability, 42-45+48, 2005.

- Qiang Maoshan, Chen Ping, Project Management Institute. Work Breakdown Structure (WBS) Implementation Standard [M]. Electronic Industry Press, 2008

- Citra Pradipta Hudoyo et al 2019 IOP Conf. Ser.: Earth Environ. Sci. 258 012051 https://iopscience.iop.org/article/10.1088/1755-1315/258/1/012051