Total Quality Management

Total Quality Management is a management approach where an organisation strive to provide customers with product and services of a high quality and a continuous improvement of the means to do so. TQM requires an establishment of a culture of improvement where quality is top priority in the whole organisation; from floor to top management. The culture needs quality in all aspects of the organisation’s operations and seeks to integrate all organisational functions focusing on compliance with customer needs. The focus is proactive; processes and productions is being done right initially in order to eliminate defects and waste.

Total Quality Management (TQM) is a Quality Management System (QMS) where a culture of improvement results in an organisation continuously improves the quality of products and service to costumers. Total Quality Management was popular in the late 1980s and early 1990s, but the use of TQM is not too widespread today due to competition from other management systems such as Lean Manufacturing and ISO9000.

Contents |

Quality Management Systems

The main goal in business is to focus on the profit and savings, and also on the additional revenue that a company can achieve. The way to reach this objective is found by eliminating errors throughout the operations, production of products and services at the level of quality desired by customers. Errors can increase amount of costs significantly. To avoid errors the Quality Management Systems (QMS) are used. The purpose of QMS is to secure quality of product and manage the communication between management and employees; telling them what is required to produce and what desired quality level to be achieved of specified products and services.

QMS consists of four main components:

- Inspection, where work is physically checked in order to secure that is has been completed satisfactorily.

- Quality Control (QC), where management control techniques is used in order to achieve fulfilment of quality requirements.

- Quality Assurance (QA), where externally accredited procedures and techniques are used in order to ensure that quality management practices are carefully followed.

- Total Quality Management (TQM), where the organization is motivated to do continuous process improvements to achieve increasingly higher levels of quality.

These four components will be further explained in the following sections.

Inspection

Inspection is ‘conformity evaluation by observation and judgment together with measurements and testing’. Usually inspection is executed by a third part who did not participate in the production of the object. The object is either accepted or rejected; following rejection goes either reworking or scrapping of the product, were additional costs follows. Furthermore, there are two more disadvantages of inspection. Firstly, the inspection process requires dedicated resources. Secondly, the way of saving expenses in performing sampling method reduces the effectiveness of inspection by itself. But still the inspection procedures are vital for safety-critical product system, together with assurance of the product capability to work to the required tolerance.

Quality Control

Quality control is focused on fulfilling quality requirements. There are numerous of operation techniques available, but often reference is made to Ishikawa’s seven QC tools, which follows:

- Cause-and-effect-diagrams (also known as fishbone chart), where possible causes for effects or problems are identified.

- Check sheet, which is a structured, planned and prepared sheet for collecting and analyzing data. It is a general tool that can be used for several purposes.

- Control charts, which are graphs that show the development of one or more processes over time.

- Histogram, a tool for showing frequency distribution or how frequently a specific error or defect occurs.

- Pareto chart, is used to show which factors are most influential. Shown on a bar chart.

- Scatter diagram, a use of pairs of numerical data where a relationship between the pair is suspected. The data is input in a graph.

- Stratification, a separation of data from different sources, so patterns can be detected with more ease. E.g. data from different production facilities.

Quality Assurance

Total Quality Management

Inspection, QC and QA all have two important limitations:

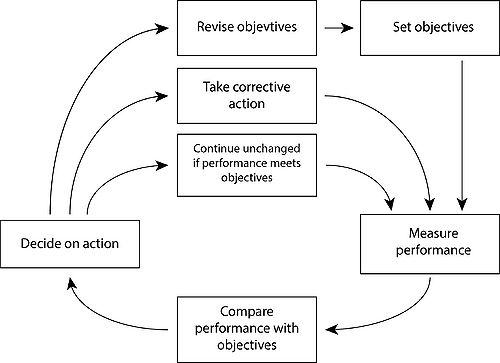

- They are first-order information loops (see figure: The Generic Information Loop) around static standards. Therefore performance is 100% if there are no defects.

- The systems only focus on operation and do not take, among other factors, customer satisfaction into account.

Thus continuous quality improvement is not a part of inspection, QC and QA.

Quality