Kaizen Event - a managerial tool for problem-solving

Contents |

Abstract

This article will look into how Kaizen Events can be used as a managerial tool for problem-solving processes in a project. It will thereby go into the category of Project Management. The article will introduce the term Kaizen Events relative to general lean principles and the Kaizen concept in Lean thinking. The article will then give an overview of and a Guide to how a Kaizen Event should be carried out and what important things to consider when doing so. The article states that Kaizen Events can be used as a bottom-up approach for rapid improvement and problem-solving beyond the context of lean manufacturing. It also states that a core benefit from carrying out Kaizen Events is creating motivation and problem-solving capabilities for the individual employees.

Keywords

Kaizen, Kaizen Event, Lean Thinking, Problem-solving, Cross-functional teams, Project Management, Lean Project Management.

Introduction to Kaizen Events

Kaizen vs. Kaizen Events in Lean thinking

Lean thinking a business strategy that revolves around removing or reducing waste and non-value-adding effort. Kaizen is however defined as a lean tool or method for achieving the 5 basic lean principles (Kaizen vs. Lean: Distinct but related, metalfinishing, January 2010). The article will elaborate on these principles in the section “Kaizen Events and Lean Principles”.

According to Lean thinking does the term Kaizen represent continuous incremental improvement, and it refers to a general way of thinking and behaving. Kaizen should be practised on a daily basis and it is about empowering and unleashing the creative power of people who actually do the work, in order to design more effective and efficient processes. This in order to spread lean thinking throughout the organization and teach the workforce how to effectively solve problems as they arise. Kaizen Events, on the other hand, are formalized activities that organization use to achieve rapid and dramatic improvements (Kaikadu) and progressively shift their culture. Kaizen events create a structured environment in which teams learn how to identify waste and apply specific lean tools to eliminate it. In this “learn-by-doing” environment, teams become more comfortable with their authority to make improvements. Under the guidance of a skilled facilitator, Kaizen Events can generate rapid results. This is however relying on the creative power of cross-functional team to design and implement innovative ways to perform work (Martin, K., Osterling, Mike, 2007, s. 21).

Kaizen Event definition

A Kaizen Event can be defined as: “A focused and structured improvement project, using a dedicated cross-functional team to improve a targeted work area, with specific goals, in an accelerated timeframe” (Farris et al., 2009, p. 1).

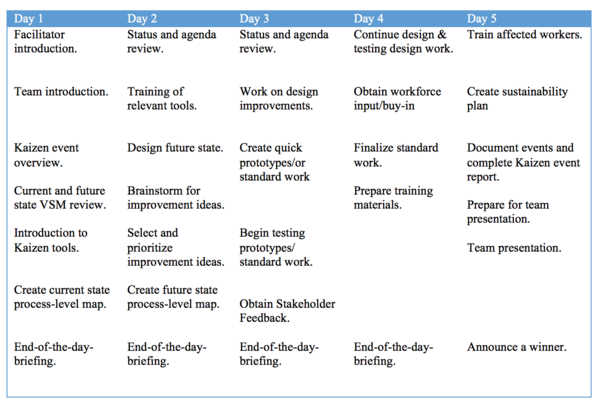

Kaizen Events are also referred to as Kaizen workshops or Kaizen Blitz or blitzen. Kaizen Events typically lasts a week, but the length can vary relative to the scope of the event (Jackson, Thomas L., 2013). This article will use the term Kaizen Events that defines a five-day event with the aim of rapid improvement. It especially goes into details with the frame of the Kaizen event as a problem-solving process in an organization.

All the activities involved in conducting a Kaizen Event or a series of Kaizen Events will in this article be referred to as the Kaizen Event Process.

Increasing use of Kaizen events

Kaizen Events are often associated with lean production and lean manufacturing (Womack et al., 1990), where Kaizen events can result in improvements in technical system outcomes, such as lead time, work-in-process inventory, and productivity. It has however also gained a reputation for providing social system outcomes, such as helping employees develop new problem-solving capabilities and increased motivation to participate in future improvement activities (Drickhamer, 2004). Given this potential of Kaizen events for producing rapid improvement in both technical and social system outcomes, many organizations appear to be increasing their use of Kaizen events (Melnyk et al., 1998). Kaizen events are an increasingly common organizational improvement mechanism aimed at work area transformation and employee development (Farris et al., 2009) and it is therefore also seen as managerial tool. This increased focus has also resulted in an expansion of the use of Kaizen events. Several companies has also started using the frame of the Kaizen Event as a problem-solving tool for concrete problems related to other areas in the company such as the R&D department focusing on product development.

Imai Masaaki and Kaizen as a problem-solving process

According to one of the formulators of the Kaizen concept, Masaaki Imai, is the problem-solving capability one of its core elements:

”The starting point for improvement is to recognize the need. This comes from recognition of a problem. If no problem is recognized, there is no recognition of the need for improvement [..] Therefore, Kaizen emphasizes problem-awareness and provides clues for identifying problems” (Masaaki, Imai, 1986, p. 9).

Masaaki claims that once a problem has been identified it must be solved and therefore does the concept of Kaizen also contain various problem-solving tools. Another core idea of the Kaizen concept is that all employees in the organization have the capability and the will to contribute to the continuous refinement and betterment of the existing activities (Styhre, A., 2001, p. 797). Instead of seeking to control and measure the activities of the employee, the managers should act as coaches, supporting the improvement activities carried out by the employees in the kaizen teams. This behaviour is facilitated in order to support a bottom-up approach where the individual employee has a say in the way problems are solved (Styhre, A., 2001, p. 801).

In his book “Kaizen - The Key to Japan’s Competitive Succes” from 1986 Massaki provides both analytical problem-solving tools based on attainable data, and more collaborative problem-solving tools based on verbal data. Today these methods are still valid and well-recognized. They are used frequently in Kaizen Event in companies around the world, but should be carefully selected relative to the scope of the Kaizen event.

Analytical problem-solving tools:

- Histograms: A visual way of presenting data.

- Control charts: Serve to detect abnormal trends with help from line graphs.

- Scatter diagram: Two pieces of corresponding data are plotted so the relationships can be compared.

- Graphs: Visual representation of data.

- Checksheets: These are designed to tabulate the results through routine checking of the situation.

- Pareto diagrams: Problems are diagrammed according to priority using a bar-graph format.

- Pareto charts can for example rank occurrences in the order of frequency.

- Cause-and-effect diagram: Characteristics of a process or a problem are analyze according to the factors that contribute to them. These diagrams are often referred to as “Fishbone” or Ishikawa (after its developer).

Collaborative problem-solving tools:

- Relation diagrams: Clarifies interrelations of a complex situation

- Affinity diagram: Essential in brain-storming method. Participant write down ideas and these ideas are grouped according to subject. Can also be used for organizing data from various media.

- Tree diagram: Interrelations of goals and measures.

- Matrix diagram: Used to displaying quality requirements into counterpart characteristics.

- PDPC (process decision program chart): Decision program chart.

- Arrow diagram: PERT (program evaluation and review technique) and CPM (Critical path method.

Kaizen Events and lean principles

The five-step process for guiding the implementation of Lean thinking in an organization is:

- 1. Specify value.

- 2. Identify the value stream.

- 3. Create flow.

- 4. Pull from customer.

- 5. Seek perfection.

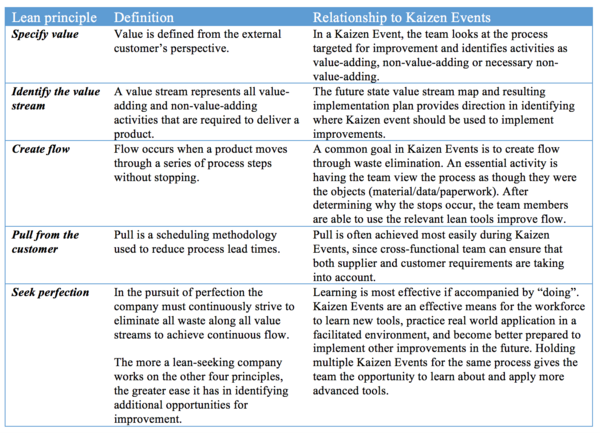

The Kaizen concept belongs to the Seek perfection lean-principle because the idea of achieving perfection is an on-going process that involves continuous improvements. In the Kaizen Events you however focus on all or one part of the other four lean principles (Martin, K., Osterling, Mike, 2007, p 5). The relationship between the 5 lean principles and Kaizen Events is explained in table 2.

Overview of Kaizen Event

General activities for a Kaizen Event

Most Kaizen events are conducted using a three- to five-day concentrated work session with typical activities including (Melnyk et al., 1998).:

- Team training

- Documentation of the current state

- Identification of opportunities for improvement

- Improvement selection (and often implementation);

- Results presentation

- Documentation of an action item list for follow-up activities

The full Kaizen Event process also includes activities occurring before the actual event, including event selection, scoping, and planning, as well as activities occurring after the formal event concludes, including follow-up actions to sustain changes and improvements. Further, activities representing the planning of the Kaizen event needed such as facilitator selection and training, development of standard event training materials, and communication mechanisms to document and distribute improvements and results (Aken, Eileen M. V. et. al., 2010).

In general, Kaizen events use general lean principle tools such as quality circles and continuous process improvement teams: identifying low-cost improvements through the application of process analysis and problem-solving tools. Both “traditional” lean tools, such as process flowcharts, cause-and-effect diagrams, and Pareto charts, and lean production tools, such as standardwork, 5S, and single-minute exchange of die. In general does these improvement mechanisms stress the key role of employee involvement, incremental improvement, and organizational culture change in driving and sustaining performance improvement (Aken, Eileen M. V. et. al., 2010, p 642).

PDCA and Kaizen Events

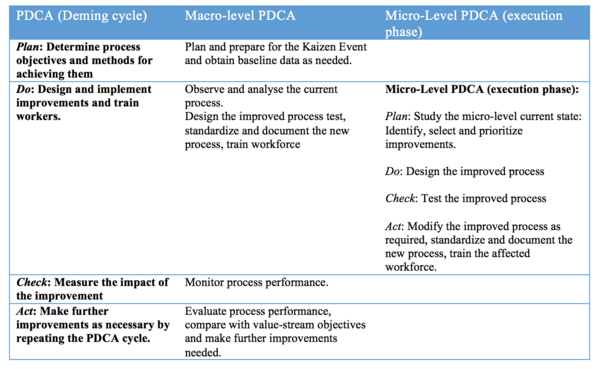

Kaizen Events use the scientific approach of plan-do-check-act (PDCA), one of the cornerstones of the Toyota Production System. The PDCA improvement cycle focus on seeking perfection rather than waiting for perfection. The PDCA cycle is present at two levels Kaizen Events (Martin, K., Osterling, Mike, 2007 p. 23). The three phases of Kaizen Events – planning, execution and follow-up (macro-level). During the Event itself (the execution phase) lies a micro PDCA cycle.

Guide for a Kaizen Event process

Basic on a literature study a generic framework for a Kaizen Event process is outlined and includes the following steps:

- Planning (“Plan”)

- Executing (“Do” & “Check” and iterative circles of PDCA)

- Implementation plan & Follow-up (“Act”)

PLANNING

To plan a Kaizen event the following activities should be done (Martin, K., Osterling, Mike, 2007, p. 99):

- Select Kaizen Event facilitator – will you use and internal or external consultant?

- Communicate the plans for the Kaizen Event to the entire organization

- Select area of investigation (scope of the Kaizen event)

- Select problem for improvement

- Select team member, define the team and team leader

- Prepare the area/scope

- Gather needed supplies and equipment

- Gather data and background information needed

- Schedule the workshop

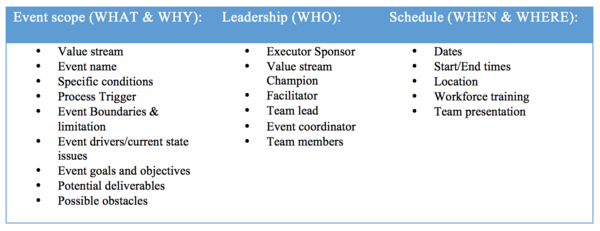

Important things to consider are listed in table 4.

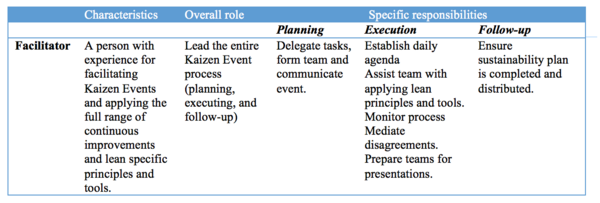

Kaizen Event facilitator (sensei)

Through the process of a Kaizen Event, the facilitator teaches the team members how to think lean, identify waste, apply specific tools and sustain their gains. The facilitator keeps the team on track from a time perspective, helps maintain momentum and assist the team in overcoming obstacles (Martin, K., Osterling, Mike, 2007 p. 40).

Kaizen team formation

A Kaizen event team represents a specific type of team—a short-duration dedicated project team (Farris et. al. 2008). Kaizen event teams must be structured to achieve tho desired outcomes (Martin, K., Osterling, Mike, 2007 p. 59):

- Short-term performance improvements results

- Long-term improvement of cultural transformation

- Teamwork critical elements in creating a continuous-improvement culture.

- Good mix of individual from across functional units in the organization.

The above should be considered relative the scope of the Kaizen event – including the context of the problem that should solved.

A different core idea of the Kaizen concept is that many problem-solving situations call for collaboration among people from different departments. When doing a Kaizen Event it is therefore believed that an important feature of the design approach is to involve people from different backgrounds because it will make it more effective to solve cross-functional problems (Masaaki, Imai, 1986, 240-241).

KAIZEN EXECUTION

To execute a Kaizen event the following activities should be done (Martin, K., Osterling, Mike, 2007, p. 99):

- 1. Orientation

- Introduce the team and assign roles

- Introduce the workshop objectives and procedures

- Distribute team supply kits and resources

- Conduct needed training and set ground rules

- 2. Understand the current situation

- If possible, observe the selected area and gather data

- Review the value stream map

- Set up areas for 5s implementation

- 3. Make improvements

- Develop improvements ideas

- Test ideas and implement the new plan

- Develop new standards

Kaizen Event tools

The tools chosen for a Kaizen event should be carefully selected relative the desired outcome of and the teams participating in the Kaizen Event.

Current State Analysis: The following tools are referred to as the fundamental tools for the root cause analysis – RCA tools (Jackson, Thomas L., 2013):

- Value Stream Mapping: This method is used to identify all relevant functions and individuals, and to understand about the process flow and to documents the current process performance. A Process flow diagram can be made from the principles of a MBPM: Metrics-Based Process Map.

- Cause-and-effect diagram: Characteristics of a process or a problem are analyse according to the factors that contribute to them. These diagrams are often referred to as “Fishbone” or Ishikawa (after its developer). It is a visual tools that aids brainstorming and document potential causes and sub-causes for an undesired effect or outcome. It provides structure to a teams brainstorming. 6 categories are often considered and are referred to as the “6 M’s”: Man (people), Material, Machine, Method (process), Measurement, Mother nature (work environment). It helps to consider full spectrum of reasons (Jackson, Thomas L., 2013).

Make improvements: This part focuses on a five-step process that provides the structure to help team generate aggressive outcomes:

- 1. Start from review current state (photos data, diagrams)

- 2. Stimulate innovative thinking (initiated by “ice breaker” exercise)

- 3. Provide improvement tools training

- 4. Conduct brainstorming session to generate improvement ideas

- 5. Evaluate and Prioritize improvement options

- The brainstorm session: There are several ways to conduct brainstorming. Most importantly is to set up common rules in the team, to avoid judgement, and to make team members confident to suggest wild ideas and make it okay to build on ideas from others. Principles of various other fields can be applied in this section, and should be chosen relative to the scope of the Kaizen.

- Affinity diagram: It is tool commonly used to sort a large numbers of ideas stemming from brainstorming into groups, based on their natural relationships.

FOLLOW-UP & IMPLEMENTING IMPROVEMENTS

Sum up of considerations for the follow-up phase (Jackson, Thomas L., 2013 p. 100):

- 1. Present the results of the Kaizen Event

- Prepare presentation

- Present the results and display results in a central area for people to read at their leaisure

- Celebrate the completion of the workshop

- 2. Follow-up

- Assign follow-up tasks and make sure they are completed.

- Prepare and conduct training

- Document and continue to tracks results.

- Consider next steps.

They key question that the Kaizen team must answer when considering its implementation strategy is what key tasks should be set up and to whom. Also it is important to consider the impact of change and proper training is therefore essential to ensure worker confidence in the new which leads to competence and, by extension, performance excellence. Effective training builds both knowledge, understanding why and skille, demonstrating how (Jackson, Thomas L., 2013 p. 161).

Sum up of factors to consider during the Kaizen Event process

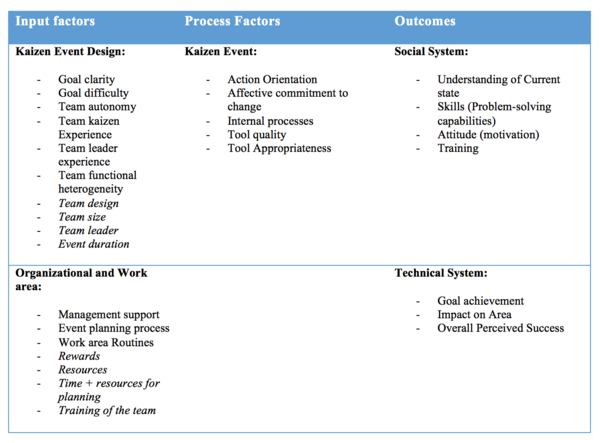

Even though the use of Kaizen Events are increasing does organizations currently lack guidelines for how to organize knowledge related Kaizen Events in order to better understand recommended practices and to evaluate current practice (Aken, Eileen M. V. et. al., 2010, p 644). Critical factors of what to consider throughout the Kaizen Event process can be useful in order to achieve full potential of the time spend on the Events (Farris et al., 2009, pp 46).

The scope and goal clarity of the Kaizen Event is key for a successful outcome. Also should the tools used should fit to the scope of the Event. It can seem obvious but since the Kaizen Event evolves around empowering the people in the company do preparation and understanding team dynamics have a high impact on the outcome. To obtain maximum impact on both employee attitude and problem-solving ability organizations should seek to maintain a high level of positive internal team dynamics, through the use of structured mechanisms (e.g., team ground rules, ice breakers, training, charters) and facilitator coaching. To increase team problem-solving capability teams should be allowed a high degree of autonomy and that the organization should use mechanisms designed to increase participant buy-in for the Event. This could for example be from clearly describing the reasons for the Event, and thereby demonstrating how the Event will positively impact both individual and organizational interests (Farris et al., 2008, pp 58). Furthermore is support from the top management essential, since it will help create a culture around rapid improvement changes and also is key for getting the right amount of resources to go through with the improvement activities.

Benefits & Challenges

Benefits

Kaizen Events have the potential to provide the following benefits to the organization:

- Understanding of the Current Value Stream

- Cross-functional team work

- Accelerated timeframe with 100 % focus (employees are relieved from their normal duties)

- Workforce development (motivation and learning capabilities)

- Training of collaborative skills (for both managers and workers)

- Structured improvement around specific goals

- Creativity before capital

- Aggressive objectives

- Rapid decisions and real-time buy-in

This article also stresses these non-measurable benefits from cross-functional team work:

- Motivation and Enhanced job satisfaction (meaningful work).

- Enhanced problem-solving capabilities.

- Better work relationships between individuals, since employees work together to solve problems.

The setup of cross-functional teams supports the positive attitude among the employees. Through Kaizen Events, cross-functional teams learn how to make improvements in a methodological way. They learn how to apply specific improvement tools. Most importantly they learn how to work with one another to solve problems rapidly and in a highly effective way (Martin, K., Osterling, Mike, 2007).

Challenges:

Kaizen Events require experience: Impressive outcomes of Kaizen do not magically appear. Kaizen Events in development settings require more planning, skillful execution and follow-up than their manufacturing counter-parts. There is therefore a need for a skilled facilitator to run the Event, and these facilitators are often chosen as external consultants. They can be good at running the Event but may lack knowledge of understanding the current state in the company.

Goal clarification & Problem selection: Problems chosen for Kaizen Events should be ones that cause significant pain to the organization, but can addressed successfully in a five-day workshop with follow-up activities (Martin, K., Osterling, Mike, 2007, p 24). It should therefore be selected carefully prior the Event so that a success outcome of the Event is possible. The complexity of the problem identified for improvement during the event can change the scope of the event. A skilled facilitator that can help the team adapt and stay on the right track is therefore essential.

Selection of tools: The tools used for creative problem solving should be chosen relative to the scope of the Kaizen Event and the Kaizen team. This can be a difficult task since it what methods are best suited changes with the complexity of the problem.

Importance of team dynamics, motivation and autonomy: The team dynamics is of high importance in a Kaizen Event, but it can be difficult predict how people work together in teams. A skilled facilitator can however help to ensure that the teams stay in the right track. The team dynamics is dependent on a long range of factors that are not easy to predict.

References

Articles:

- (Aken, Eileen M. V. et. al., 2010)

Eileen M. Van Aken, Jennifer A. Farris, Wiljeana J. Glover, Geert Letens, A framework for designing, managing, and improving Kaizen event programs, International Journal of Productivity and Performance Management, Vol. 59 No. 7. 2010, pp. 641-667.

- (Drickhamer, 2004)

Drickhamer, D. (2004), ““Just-in-time training”, Industry Week, Vol. 253 No. 7, p. 69. EFQM (2010), Assessing for Excellence, European Foundation for Quality Management, Brussels.

- (Farris et al., 2008)

Jennifer A. Farris, Texas Tech, Eileen M. Van Aken, Virginia Tech, Toni L. Doolen, Oregon State University, June Worley, Oregon State University, 2008. Learning From Less Successful Kaizen Events: A Case Study. Engineering Management Journal 20, p. 10-20.

- (Farris et al., 2009)

Jennifer A. Farrisa, Eileen M. Van Akenb, Toni L. Doolenc, June Worleyc, 2009. Critical success factors for human resource outcomes in Kaizen events: An empirical study. International Journal of Production Economics. Volume 117, Issue 1, January 2009, Pages 42–65.

- (Geert, L. Et al, 2006)

Letens, Geert, Jennifer Farris, and Eileen M. Van Aken,. “Development and Application of a Framework for the Design and Assessment of a Kaizen Program,” Proceedings of the American Society for Engineering Management Conference (October 2006).

- (Melnyk et al., 1998)

Melnyk, S., Calantone, R., Montabon, F. and Smith, R. (1998), “Short-term action in pursuit of long-term improvements: introducing Kaizen events”, Production & Inventory Management Journal, Vol. 39 No. 4, pp. 69-76.

- (Styhre, A., 2001)

Styhre, Alexander, 2001. Kaizen, ethics and care of the operations management after empowerment. Journal of Management Studies 38:6 September 2001.

- (Womack et al., 1990)

Womack, J., Jones, D. and Roos, D. (1990), The Machine that Changed the World, Harper Collins-Rawson Associates, New York, NY. Yin, R. (1994), Case Study Research: Design and Methods, Sage, Thousand Oaks, CA.

Books:

- (Jackson, Thomas L., 2013)

Thomas L. Jackson, Kaizen workshops for Lean Healthcare, Rona Consulting Group & Productivity Press. ISBN 978-1-4398-4152-5.

- (Martin, K., Osterling, Mike, 2007)

Karen Martin; Mike Osterling (October 5, 2007). The Kaizen Event Planner. Productivity Press. p. 240. ISBN 1563273519.

- (Masaaki, Imai, 1986)

Masaaki, Imai, 1986. KAIZEN – The Key to Japan’s Competitive Succes.