Product breakdown structure

The overall definition of a project is something which creates a unique product, result or service. Furthermore a project is something temporary, which is granted with a beginning and an end, so it is basically meant to die. However a operation is something which continuously gives support and can be foreseen as something not intended to die.

Managing projects is something which requires structure in order to have the best rate of success. By not having any structure there is a severe risk of achieving projects where the different tasks will start to work against each other, which could result in the requirements from the stakeholders not being meet, bad communication and collaboration among the involved parties and the time schedule and budget might have to be extended. Therefore lacking or missing structure is a project managers worst nightmare and must be avoided. The best way to achieve such order from the very start is to apply some kind of management process to assure that the project is steered and kept in the right direction. Among the many tools available the project scope management could be chosen. When working through a management process like this subject like this, the covered areas will be: Plane scope management, Collect Requirements, Define Scope, Create WBS "Work breakdown structure", Validate Scope and Control Scope. Within the project scope management process the creating WBS "Work breakdown structure", is a tool which has some large benefits in order to obtain a good cost-, time planning and execution of the project. There are different types of "Breakdown structures", determined on the given approach and though out this article the focus will primarily be on the PBS "Product breakdown management" and the pros and cons by using this tool in project management.

Contents |

Product breakdown structure "PBS"

History

The historical creation of the PBS is unknown. However it is known that PBS is a tool which contributes to the Work breakdown structure, which were invented by The United States Department of Defense (DOD) back in 1960's, but the tool were finally implemented in the PMI "Project Management Institute" PMBOK in the 1987 as a standardized tool. The Product breakdown structure tool is wisely applied when having some kind of production line with many sub products. Thinking of a car, this is a final product assembled from a lot of sub products. The product breakdown structure can be used to create an organized hierarchic illustration of the car.

Why is Product Breakdown Structure important in construction

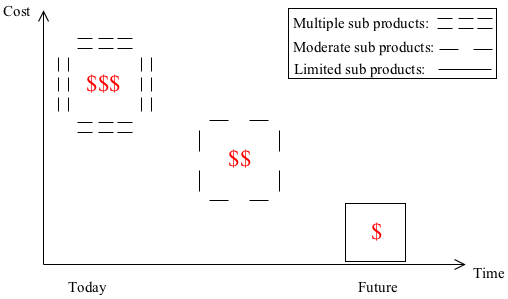

Due to the innovative world we seek new ways to make things more effectively and efficiently. When it comes to construction the resent technology are prefabricated elements, which are assembled on site. The industrialized construction approach makes it possible to reduce the human factor which tends to be a significant contributor to the uncertainty. With this approach the benefit of making a product breakdown structure in a construction process, can now take its place. At the figure below it is illustrated how the "old" well known construction tend to be consisting of a lot of sub products, which relay an human resources in order to be assembled. When moving towards the future it is illustrates that the assembly will relay less on human resources and more on prefabricated sub products, were the human resource is minimized. However the products will still need production e.g. the concrete wall. The main focus upon the approach is that the e.g. concrete wall could be produced externally under some certain conditions, which minimizes the cost deviation, because new this sub product is part of a well planned production line.

Please note that the cost is only focusing upon the expense for the human labor on site. Even if the whole project would end up with the same end prize, then the industrialized construction technology will still be the one with the smallest uncertainty, because according to the product breakdown structure it easy to predict and illustrate the cost for each sub product, because a fabricator can give a specific price for each sub product.