Construction consolidation centre

For large scale construction sites or construction sites in urban environments, a CCC is sometimes used to manage the logistics within material deliveries. A CCC is a place close to one or more construction sites, which facilitates the flow of materials going to the site through the supply chain. The CCC is comparable with a warehouse, since the construction materials are stored in the CCC until they are needed at the site. Another advantage of a CCC is the opportunity to reduce waste (or carbon emission from e.g. traffic) from the construction site and to recycle non-used materials. Despite the mentioned advantages of using a CCC, this is a relative new term, which almost only has been used in the United Kingdom. The question is, why is this not more commonly used worldwide? It is interesting to investigate and describe the term CCC and the advantages/disadvantages compared to e.g. the “deliver in time” method or other alternatives. It is essential to describe and discuss things like: The benefits of using a CCC, when is it the right choice, what is the optimal location and how is it implemented in a construction process? All this will be covered in a Wiki-article, which hopefully will be a short guidance to future project/construction managers, when the logistics of a construction site is considered, especially regarding where to use and not to use a CCC.

Contents |

Introduction to a construction consolidation centre (CCC)

The basic idea

As mentioned, a CCC is a part of the supply chain for projects in urban environments. The idea is to reduce the number of vehicles delivering materials to the site. Deliveries may interact and interfere each other, if they are uncoordinated, which is often the case. A CCC is practically the same as a big warehouse. This warehouse facilitates one more construction sites at the time. Sometimes construction sites are congested, since the materials must be stored at the site, which could lead to material damage and waste. Material damage and waste are also one the main things to prevent using CCCs. At the same time, it possible to protect the materials better, when they are stored in a CCC, as it is easy the keep them save and dry (the materials are stored indoor in a CCC).

In a CCC the suppliers deliver a high amount of material or all the materials needed for the construction. Thereby, the site manager can order what is needed for the next part of the program face (also mentioned as just-in-time basis ), instead of having a high number of deliveries to the site, which possibly could disturb the construction workers, and keep them busy with other things than what they are supposed to (construct the building). Having a CCC deliveries to a site can be reduce drastically, since the daily deliveries depends on which face of the program the construction is in. However, large items though (e.g. a big steel girder or big concrete elements), must be delivered directly to the site. These items though, are often installed immediately at the site, and they are not in the way, for a long time.

Traffic and pollution

Another important reason for the development of CCCs is traffic. IN London for instance, the traffic is more and more affected by material deliveries. As mentioned, they are often uncoordinated, and they can have a huge effect on the traffic close to the site. When a CCC reduces the number of vehicles coming to the site, the problem about traffic should be solved, since fewer cars means less traffic. If the traffic is reduced the emission of C02 is also reduced, and at this is very important for the global environment. CO2 could also be reduced utilizing trucks with a low amount of carbon dioxide emission, to deliver the materials from the CCC to the site(s).

Location

The location of a CCC is of very high importance. The CCC cannot be located to far from the construction sites. Furthermore, it is considerably to consider which road the haulers should take to have less impact on the daily traffic. This is often done by placing a CCC close to big roads like motorways. Some good rules of thumb about the location of a CCC have been stated by Greger Lundesjo in the report “Using Construction Consolidation Centres to reduce construction waste and carbon emissions”[1]

- It is desirable to locates a CCC within a range of 30 minutes from many construction sites, however 45 minutes is the absolute maximum

- A haulier should be able to make two to three deliveries from the CCC to the site within and eight-hour shift

- A CCC should be close motorways or major roads, to reduce the impact on the traffic as much as possible

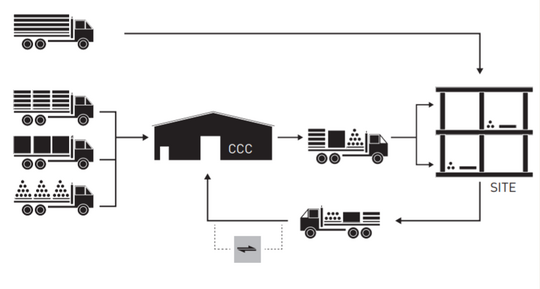

Explenation of the graphic sketch of a CCC

The figure (to the right) explains and summarizes pretty good, how a CCC works. In the upper left corner, we see a vehicle with big construction materials (big steel girders or concrete elements), these must be delivered directly to the site. In the left corner, there is three vehicles. These represent the rest of the construction materials, which are needed for the construction project. These materials are delivered and stored at the CCC (in the middle). When there is a call of from the site, a new vehicle is loaded, with a lot of different materials, and then finally taken to the site. The last truck (in the bottom) represents material which have not been used at the site, and thereby it is delivered back to the CCC.

Advantages

Using CCCs has a lot of advantages in the construction industry. Not only for the construction companies but also for the suppliers and developers. A CCC could reduce the construction cost and some examples shows improvement of 29% [2]. of the construction time. This is some of the advantages for the developers. For the suppliers it could be mentioned, that there is no (or only less) waiting time at delivery, and the delivery costs can be reduced too, since the suppliers are able to hand-in a lot of materials to the CCC at the same time. Some of the more general advantages is stated in the following:

- The traffic to the site could be reduced with up to 70%

- CO2 emission is reduced, because of the reduced number of deliveries

- The material waste would reduce to around 7.5% and in some cases, up to 15%

- The principal of “Reverse Logistics” can be used

- At the CCC the materials are often better stored than on the site

- The productivity of the construction workers is improved, since there is less waiting for the materials at the site

- Over ordering is often reduced. Usually it is 10-15% without use of a CCC

- The programme is often faster and more certain

The numbers of the improvement is based on studies made by Greger Lundesjo in the report “Using Construction Consolidation Centres to reduce construction waste and carbon emissions”[1] and "Designing Building Wiki" about CCCs.[3].

How to implement a CCC in the project programme?

In the following the implementation of a CCC will be evaluated according to whether to use it or not, according to the project organizing and finally the planning process.

What decides whether to use a CCC or not? (Limitations)

The first thing to evaluate is the size of the project. For small projects it makes no sense, to create a brand new CCC. This is due to the short construction time and to the low amount of materials needed. However, it could be an advantage, for small projects, to use an already existing CCC. Since they probably have a lot of the necessary material.

The other things to evaluate are e.g. the materials used in the project and the location of the project. Some projects, such as wind turbines and hangers for flights, are often made by with big steel components. In that case it will not make any sense to have a CCC. In that case, it is often easier to deliver the components directly to the site.

If a site is in a location, where the access is sufficient for material vehicles (close to motorway, little traffic around, easy to load/unload etc.), a CCC might not be the right choice. Though, it is also important, that the site itself has space enough to store the materials in a safe way.

Effects on project organizing and the planning process using CCCs

If the above things about implementation of a CCC has been considered, and it is evaluated that a CCC is the best choice for the project, it is often the main contractor who takes this decision. Though, all the firms involved (from suppliers to main contractor) often see the benefits, since it often reduces the costs of transportation for each firm.

The next part of the project organizing and planning process, is to decide whether to use an existing CCC or make a new one. As already stated, it is a benefit to use an existing CCC at least for small projects. However, if it is possible, it is applicable for bigger projects too, since it will be cheaper. If that is not the case, it is possible to make a new one in collaboration with other construction firm. It is also possible to create a CCC for one firm only, however it is very unusual, and only shared CCCs are covered in this article from now on.

CCCs could also be made by help from government. If a project is big enough, the government might see the advantages from an environmental point of view. Thereby, they could in somehow help implementing a CCC. This could be a good idea, if a city faces major construction project e.g. a metro system. This will at the same time include several contractors.

If a construction project is considered and a CCC is associated, the next planning process is the one which really benefits from the CCC. The CCC manager (warehouse manager) must make sure, that the needed materials are ordered or on the stock at the right time. The easiest way to do that, is to order all the material for the project in the beginning, and store it at the CCC. Then the site manager can order the needed materials at a certain time of the program face, as already mentioned.

Issues to prevent and disadvantages

Until now, the usage of a CCCs has been described and presented from a positive point of view, meaning that only the advantages have been mentioned. Now it is time to cover some of the disadvantages and issues when managing a CCC and using a CCC.

Issues to prevent managing a CCC

Talking about Construction Consolidations Centres the “London Construction Consolidation Centre” is often used as a reference point. It was a trial project from 2005-2007, to see the effect of a CCC. A report of the LCCC addresses some of the key issues of the LCCC and CCCs in general.[4]. Some of them are discussed in the following.

To have a successful CCC, a high amount of the materials must be distributed through the CCC. Otherwise the CCC becomes needless, since there is not a sufficient financial benefit. Another financial aspect is to ensure that the CCC is self-financial. Depending in the size of the CCC, it must serve a certain number of sites to ensure that. The financial aspect is of high importance for owners and managers of the CCC. All in all, they need enough construction sites to be facilitated through them, but also a big enough amount of the material.

Another issue of a CCC is the limited life span. No matter where it is located it will eventually not be financial sustainable, since there are not enough construction sites with the range of 30 to 45 minutes. In the end, it can be too expensive to set up a CCC and close it down only a couple of years later.

Disadvantages using a CCC

When a contractor decides to use a CCC, there is number of risks, which must be considered. If one the other contractors, using the CCC, goes bankrupts the others are effected. Suddenly, there is once less to use the CCC, which could affect the economy. Furthermore, the materials for the project(s), stored at the CCC, are not distributed to any site, and it may affect the whole flow of the CCC (in nothing goes out, nothing goes in). It is practically the same if one project is delayed. For the site manager, or the manager facility manager at the site, some managing skills are required. The construction phase depends very much on this person. At the end of the day, he must know exactly what has been done and what is to be done tomorrow. Furthermore, he should know exactly which materials are needed for the next day. The principle of a CCC depends on daily deliveries, and the contractor must ensure, to have at skilled person coordinating the facility flow. Otherwise, delays will happen, and the usage of the CCC fails. Using a CCC, the logistic manager of the contractor might not be fully aware everything needed is at the CCC. The disadvantage in this perspective, is that the logistics are outsourced. However, if the logistics manager has access to the IT-managing system of the stock, it should be no problem.

References

- ↑ 1.0 1.1 1.2 Greger Lundesjo , 2011, Using Construction Consolidation Centres to reduce construction waste and carbon emissions Available online

- ↑ http://www.spt.co.uk/wmslib/Liaison_Group_papers/ccc_apr09.pdf

- ↑ https://www.designingbuildings.co.uk/wiki/Construction_consolidation_centre_(CCC)

- ↑ Transport for London, 2008, London Construction Consolidation Centre Final ReportAvaileble online

Annotated bibliography

Greger Lundesjo , 2011, Using Construction Consolidation Centres to reduce construction waste and carbon emissions