Quality control

Defects and errors in construction projects have been subject to attention in the medias and debates through out the years. There exists a general consensus of a lack of quality on the construction sites, thus an increasing effort have been made to improve the quality of construction projects by a number of political initiatives [1]. When managing quality in a project an important aspect is Quality Control, which is the topic of this article.

Contents |

Definition of Quality Control

Quality Control (QC) is a part of quality management of construction projects, and to be more exact QC is at the heart of conformance management. The aim of QC in construction projects is to assure high quality of the construction being built and the individual processes in the project. In this content “high quality” means fulfilling standards and the established quality requirements of the specific project [2]. It is important to investigate the causes of the arising problems, as well finding ways to eliminate unsatisfactory performance when performing QC, thus both corrective and preventive QC techniques are essensial.

Product Quality Control vs. Process Quality Control

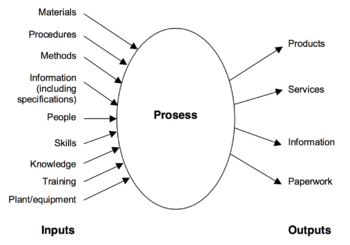

QC deals with the specific products as well as the processes as mentioned. A certain understanding of the process or product is needed in order to perform QC of either part. A process is the transformation of a set of inputs into the desired output. Figure 1 shows the inputs can be materials, procedures and knowledge. Each process in a construction project can be analyzed by itself and afterwards actions can be determined in order to improve the process, thus the process QC become preventive [3].

Examples of process QC can for example by:

- Measuring the temperature of the concrete during casting and check if it fulfill specifications.

- Controlling the quality control process by checking if the quality control methods agreed upon are carried out [4].

- Checking if the pile movement during hammering process correspond to the predicted movement, when constructing the pile foundation.

QC of af product concerns instead the quality of the output/result of the a process in the construction project. It can be a product of a process in the design phase as well as in the construction phase. The output doesn't have be a physical product but can as well be a service, information or conducted paperwork as illustrated on Figure 1. Examples of defects that product QC deals with are:

- Missing information in drawing material

- Moisture damage of a construction element

- Cracking in a welding

Performing quality control

| Primary inputs | Primary outputs |

|---|---|

|

Progress data Deliverables Quality plan |

Quality control measurements Verified deliverables Inspection reports Change requests Corretive actions |

In order to perform QC, tools and inspection procedures are needed. These inspection procedures and QC tools are specified in the part of the quality management called Quality Assurance [2]. The primary inputs and outputs of performing QC in construction project given by the standard DS/ISO 21500 [5] are shown in Table 1. Here it can be seen that QC has a high dependency of good plan-ning, as the primary inputs are a result of planning the quality in the project. The primary outputs indicate, that QC is not only a checking if requirements are meet, but it also includes documenta-tion, communication and analysis. Further more it is seen that QC also have to prevent defects and non-conformance from taking place.

The standard DS/ISO 21500 [5] states that QC should be performed during the whole project life cycle and that it includes following aspects:

- Monitoring the quality of the processes and detect defects.

- Analysis of the causes of defects and non-conforming performance.

- Eliminate unsatisfactory performance by identifying preventive actions and change requests.

- Communication of the changed requests and necessary corrective actions to project organization members.

Documentation is not mentioned directly by the standard, but it is implied in the last aspect "communication" as it is impossible to tell the craftsman which corrective actions that have to be fulfilled without. The documentation can made with control tables, but in large construction projects digital quality documentation is preferred as many parts perform quality control. By using digital documentation like "digitjek”, ”C-web” og ”Ajour” position and date of the defect can be noted on the layout drawing, so the craftsmen get a clear outline of defects [6].

Correct, prevent & predict

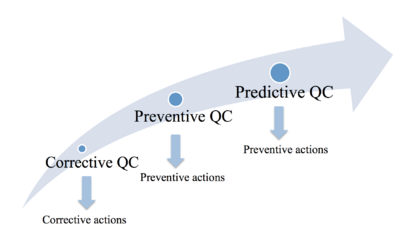

With the increased focus on minimizing non-conformance in construction projects the main goal of QC have shifted from a corrective to a predictive policy as illustrated on Figure 2. The intention of this shift is to predict the errors and defect, so they can be prevented. By achieving predictive and preventive QC the coast of the project will also be minimized as well as time will be saved. In the following the three policies corrective, preventive and predictive QC will be clarified.

Corrective Quality Control

Corrective QC is necessary when non-conformance or a defect is found or a fatal event has occurred, thus corrective QC is defined as a reactive approach. This approach of QC is necessary because unexpected events and defect always will occur in construction projects. The ideal project where all problems are prevented is hard to establish, since many people, partners and processes are involved in the project. Questions like “have we met the requirements?” and “what went wrong?” are asked here. Corrective QC deals with critical defects and the less serious defects, which doesn't meet the requirements.

This type of quality control can be very expensive according to what corrective actions needed to be conducted. Correcting serious errors can also be very time consuming depending on how many parts that have to be involved, and if new material deliveries are necessary.

In order to correct non-conformance, knowledge of the causes to the problem has to be obtained. Performing corrective QC can be accomplished with different techniques, and one technique “cause and effects diagrams” is elaborated in following.

Preventive Quality Control

John S. Oakland states:

Specification, requmendations, regulations, experience

Continous, delivery and start-up control [6]

A way to prevent expensive corrective action to quality problems, continuous QC has to be performed. This can for example include thermo graphic measurements of the first rooms finished, and non-conforming performance is found then preventive actions can be made to assure the quality of the remaining rooms.

Control at delivery of for example reinforcement and concrete elements is very import, as these elements often are shot in and hidden, thus later control is impossible. Poor quality of these elements could be fatal as it can result in construction failure, which can be prevented by performing quality control at the delivery.

Start-up control at the shift between contractors can prevent fatal errors from occurring. This way the quality of the previous work is assured and the following work is not going to hide defects that potentially can result in critical errors, that will be very expensive and time consuming to correct.

Stop the line

Predictive Quality Control

In order to be preventive you often have to be predictive.....

Monitoring

Digital tools for inspections

Sensor systems

Radio Frequency Identification (RFID)-based quality management system, which functions as a platform for gathering, filtering, managing, monitoring and sharing quality data.

Quality control techniques

Skriv noget om 7 tools Ishikawa...

Cause and effect diagrams

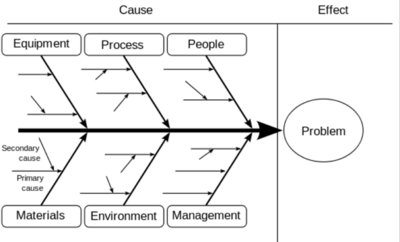

Cause and effect diagrams also go under the names “fishbone diagram” (due to their shape) and “Ishikawa diagram” (after the techniques inventor). The reason for the name “cause and effect diagram” is that the diagram is separates the problem (the effect of the causes) from the causes. The basic idea of the technique is to work back form the problem by asking: “why did it occur”, and in that way finding the different roots to the problem [2]. Each cause is thereby found by using a form of brainstorm technique, and they are grouped under different categories. A cause can either be a primary cause or a secondary cause to the primary cause. When illustrating the causes this way, the diagram takes form as a fish skeleton as shown from Figure 3.

A cause effect diagram shows there often are several roots to non-conformance and defects, and that several corrective actions have to be performed. This allegation becomes clear by grouping the causes under different categories, because it illustrates the difficulties of complex processes. The categories often include people, process/methods, equipment/machines, material, environment and management, as these are some of the basic elements in construction projects [8].

This technique can also be used as a preventive QC tool. In this way the problem have to be predicted before it occurs and then the problem can be prevented by making qualified decisions for the actions and processes that have to take place. The difficulties will be to predict all the causes to a specific problem desired to be prevented.

Statistical process control

Statistical analysis of data obtained from similar projects, and control chart can be used to determine if the outcome of the analysis is tolerable. As this technique requires data logging of previous projects, the possibility of implementation of the technique in a construction process have to be discussed here as the complexity and conformance requirements in construction projects can make the technique less effective even though the construction process is a repetitive process overall.

Performance measurements

Value stream mapping

Discussion

What is good quality control - Includes early, continuous control [1]

Benefits of good quality control

Consequences of poor quality control: cost of rework see [1]

Limitations

The requirements have to be clear (from the client to the designer (architects and engineers), as well as to the entrepreneurs and craftsmen

Operationally orientated and doesn't take factors as customer satisfaction into account

Project specific control

Time – there have to be time to do it.

Knowledge – people have to understand the process in order to control them.

Not enough ressources from the designers

Annotated bibliography

References

- ↑ 1.0 1.1 1.2 Schultz, Casper S., Jørgensen, Kirsten, Bonke, Sten and Rasmussen, Grane M. G., Architectural Engineering and Design Management, Taylor and Francis Group, 2015, " Building defects in Danish construction: project characteristics influencing the occurrence of defects at handover"

- ↑ 2.0 2.1 2.2 Winch, Graham M., Wiley-Blackwell, 2010, "Managing Construction Projects, 2nd edition "

- ↑ Oakland, John S., Rutledge Taylor and Francis Group, 2008, "Statistical Process Control", Sixth edition

- ↑ IRMI, "Construction Quality Management", access: 12-06-2017,https://www.irmi.com/articles/expert-commentary/construction-quality-management]

- ↑ 5.0 5.1 5.2 Danish Standards, 2013, "DS/EN 21500: Guidance on project management, 2nd edition

- ↑ 6.0 6.1 Jørgensen, Kirsten; Schultz, Casper S.; Bonke, Sten, Technical University of Denmark, 2013, "Processer og metoder i det fejlfrie byggeri: Erfaringer og anbefalinger fra projektledere i entreprenørbranchen"

- ↑ 7.0 7.1 The church of Jesus Christ of latter-day saints, "Helaman 1–6", access: 12-06-2017, https://en.wikipedia.org/wiki/Ishikawa_diagram]

- ↑ 8.0 8.1 Wikipedia, "Ishikawa diagram ", access: 11-06-2017, https://en.wikipedia.org/wiki/Ishikawa_diagram]