BIM-based information flow during construction phase

Interaction among all stakeholders and integration of information throughout the project life cycle is fundamental to achieve a successful project. Building information modelling (BIM) is a method of Communication in Project Management enabling continuous information flow to translate the owner’s value preposition into a successful project. The interaction is more flexible and shared transparently between the different users. More specific the article will go through how BIM enables the execution of the construction phase.

BIM is an integrated method of digitizing the construction process. Throughout the life cycle of the building, from idea to demolition, digital building models will be the focal point for all the construction project activities and cooperation between the various parties. BIM is both a model and a working method. BIM means closer cooperation between parties and branches out to each participant participating in a project. For the construction phase, BIM will enable easier communication between the contractor and the suppliers and also tracing all the operations and changes.

The purpose of this paper is to see both the limitations and advantages of this method of information flow. First the paper will make a description and application of BIM during the construction phase. Further some limitations will follow, before a conclusion. BIM is implemented in many projects all over the world. In many projects this has played a crucial role in achieving a successful project.

Contents |

Purpose

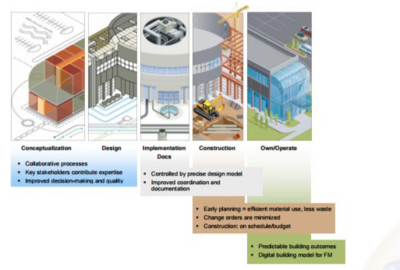

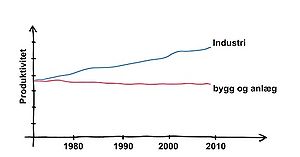

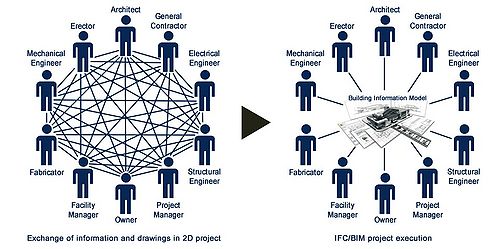

During the last thirty years the productivity of the construction have decreased compared to other industries. The basis of construction is that many disciplines have to work together with the same information. During conventional information flow, the information is exchanged through hard copies, which often result in misconception and errors. Growing digitalization of the construction industry is a result of this, by changing working method from document-based to model-based. The basis of a successful construction process is therefore good coordination and communication. Many places BIM models are a requirement. During the construction phase all the different disciplines will have an individual model where every component of the building have corresponding digital component. These models are further are collaborated together and exchanged with all participants, in an open format called IFC. All the digital components have all information standardised though Building Smart Dictionary. In this way all participants have the necessary information available when they need it, and it is always updated. [1]

It is important that project participants “think inside other people’s boxes” to better understand how the work can provide value and identify project delivery needs from the outset. By using BIM the participants do not only see their own model and discipline, but also see how it is coherence with other disciplines. A basis for BIM transformation is that incomplete or delayed information risks the perceived integrity of the entire system, information will always change during the process.[2]

The BIM model is designed as a communication tool with the contractor and subcontractors to coordinate the project on site. Administrators on site are often equipped with digital tablets, giving them immediate access to plans, specifications and other pertinent information on the construction site. This reduces response time to drawing changes, field modifications and distribution of information to all team members.Advanced equipment and technology enable the project model to reside at the site for use in clash detection, multidiscipline team coordination, drawing modifications and schedule refinement. These advancements in technology also make it possible for portions of the design model to be sent directly to fabricators for pricing, coordination and production. This resulting in better quality, efficiency and delivery on site. [3]

Application

BIM are applicable during the whole life cycle of a project. As this article is focused on the construction phase, the increased application during facility management will not be discussed to a large extent. However the work with BIM that are done before the construction phase is crucial for the use during the construction phase.

First the owner documents all its demands for the building in a database. Then the building models are made in coherence to the demands. All users will make a model of their profession. For example MEP model, architectural model, construction model etc. These concepts are modelled in the BIM environment, and result in individual comprehensive building information models that are integrated into one central model. This central model and individual models allow two-way information sharing between the different participants in real-time as well as prompt adjustments of the model information after integrating and coordinating all the data. The models are made with different objects from an object library in the software. The software automatically save information about the location in the building. Then the consultants add the information of dimensions, material, U-values and other requirements. The architect place the building in a digital map, so the contractor knows exactly the building is placed. Then the BIM models can be used to coordinate the disciplines and to do analysis of both project cost and life cycle cost, and to do analysis of energy use and other environmental analysis for environmental certification. The BIM model is then sent to the local authorisation to get a building approval. [4]

If the prior phases were implemented correctly, it should be straightforward to issue construction drawings which have accurate information for the site plan, floor plans, foundation, and materials (with their suppliers). There will be accurate drawings also for mechanical, electrical, lighting, and HVAC systems.

Then the BIM can be used to execute the construction. It is fundamental for the planning the construction phase and to communicate with the suppliers about offers and environmental impact of products. When the best offer is chosen, this new and precise information of each object is transformed into the BIM models.There is much to gain during the on-site construction process by extending the application of the BIM philosophy. There is also scope to drive the automation of the construction - while also introducing higher levels of quality control and safety - through the method of digital pre-fabrication. This can enable modularised elements off-site and then assembled with greater certainty for a faster and more predictable programme. [5]

The ability to access BIM on-site through mobile tablet devices, field operatives can gain instant access to the latest information from the digital model and the latest documentation. BIM data can also be used for progress monitoring against the original construction schedule or obtaining up-to-date material lists. Other routine activities such as snagging, safety and quality reporting can all be facilitated more effectively by integrating this data digitally with the BIM database.

Continual refinements and cost savings should be realised by utilising the BIM data to aid communication with on-site operatives and to verify initial cost and scheduling on each work package in relation to current progress..[6]

The Construction Manager and field supervisor will work with the design team to make sure that the design intent is followed, and they will run their own Clash Detections on all models. With monitoring and workflow tools, identified problems can be reported and tracked through resolution. Construction can be simulated to make sure everything is being built on time by using methods of 4D-Planning in Construction Management. It's essential for the viability and success of any construction project to control that the real construction cost adjust to the planned budget. BIM technology allows this control from the beginning to the end, facilitating automatic quantity reports and valuation in any phase of execution works. It also allows a more precise valuation of costs for construction processes, which can be studied and programmed in a real-time 3D environment.

BIM will also affect the safety on site. Particularly on a constrained site, lay-down areas and lifting zones can be analysed prior so as to ensure safe working. Working spaces can also be visualised. [7] [8]

After the project is constructed and handed over to the owner, this information is still available, and can be used for facility management, as for renovations. BIM can also be a important part of Lean construction and other tools/theories in project management.

BIM has created a solid connection between design and construction that had never been felt before. Instead of asking how we can get architects, engineers, and construction managers to collaborate efficiently, we are now asking how we can use BIM to make the process even faster and more efficient.[9]

Limitations

BIM require a great degree of standardization within national borders and international. Internationally efforts of standards for information exchange take place through IAI / IFC, buildingSmart, but it still causes problems to some extent. Many of the problems occur when projects are crossing borders, there is not a international standardisation yet. [8].

A large limitation is relates to the level of BIM experience and expertise of the different participant and stakeholders. Having gaps in the experience level of the different BIM users, will create issues in the effective communications between the project participants and stakeholders. Also in managing to make the models in the best and most efficient way require some experience, that will take some time and resources to achieve.

Some BIM models, such as AutoDESK Revit, have low levels of interoperability; the tension between proprietary and open systems inherent in CAD is being reconstituted in BIM. Interfaces with other information systems in construction – notably geographical information systems (GIS) and enterprise resource management systems (ERMS) remain rudimentary.[8].

As BIM have a high range of operation systems requirements, it has an extensive initiative cost. For large firm the later saving are so large that it is no issue. For smaller form this might be a large decision. [8].

Some limitations concerning BIM have a beginning of a solution. As the shift from 3D through 4D to nD incorporating analytic decision support capabilities is at an early stage. However 5D (estimating), 6D (sustainability) and 7D (facility management) are used. More on this can be found on BIM as a Management Tool in Construction Projects. The potential for simulation using agent-based technologies is in its infancy.[8].

Debates are developing around which member of the project coalition should own the BIM – the designers who generate it or the contractors who most benefit from it. In fact, it appears to be clients who are instigating the use of BIMs, probably with a view to the asset management benefits of BIMs through life.[8].

The construction site is a very dynamic place to be. New processes and tools such as BIM and Revit are making big strides in how the process occurs for the first conceptual thought and continuing through the lifespan of the building. It is important to remember that BIM does not solve all construction coordination issues; however, people, collaborative teamwork and the advantages of BIM help us create an open and transparent process for team members to design and build successful projects.

References

- ↑ Building Smart. (2014). BuildingSmart: Hva er Åpen BIM. https://buildingsmart.no/hva-er-apenbim/ BuildingSmart/. (21-06-2017)

- ↑ Scripac, B (2017). BIM: What does the owner want. https://www.bdcnetwork.com/blog/bim-what-do-owners-want?eid=216297987&bid=1726802/. (21-06-2017)

- ↑ Krueger, K (2013). What BIM means to the construction process. http://www.hksinc.com/wp-content/uploads/What-BIM-Means-to-the-Construction-Process.pdf/. (21-06-2017)

- ↑ Building Smart. (2014). BuildingSmart: Hva er Åpen BIM. https://buildingsmart.no/hva-er-apenbim/ BuildingSmart/. (21-06-2017)

- ↑ Building (2011). BIM during construction http://www.building.co.uk/cpd-8-bim-during-construction/5029360.article/. (21-06-2017)

- ↑ Building (2011). BIM during construction http://www.building.co.uk/cpd-8-bim-during-construction/5029360.article/. (21-06-2017)

- ↑ Winch, G (2010). Managing Construction Projects, second edition. (21-06-2017)

- ↑ 8.0 8.1 8.2 8.3 8.4 8.5 Winch, Graham, M., 2010, Managing Construction projects, second edition

- ↑ Isaac, A (2012). The Process of BIM from Design to Construction https://www.augi.com/articles/detail/the-process-of-bim-from-design-to-construction/. (21-06-2017)

Annotated bibliography

- 1. buildingSMART Norway 2014, “Hva er åpenBIM".

- Summary: This link show a outline from Spring BIMForum conference on what the owner want, how to develop BIM further and how the situation is today.

- 2. Building design construction 2017, “What does the owner want".

- Summary: BuildingSMART have a lot of information about how open BIM solutions are used, here it is in Norway. On this link a 5 minutes video is given to explain how BIM is used and why we use it.

- 3. Innovate Magazine, number fifteen 2013, “What BIM Means to the Construction Process.

- Summary: Innovate magazine have made an article with a short summary on how BIM is used today, and is based on experiences from the field.

- 4. building.uk 2011, “DPD 8: BIM during construction".

- Summary: This link show what BIM are used for in the difference staged of construction, and more specific in the design and execution phase.

- 5. Winch, G. M., 2010, Managing Construction projects, second edition

- Summary: Managing construction projects, 2nd edition draws

- 6. Autodesk User Group International 2012, “The Process of BIM from Design to Construction".

- Summary: Mosty how BIM is used in the design phase, but some from the construction phase as well.[[Category:Construction]