Product breakdown structure in construction

The overall definition of a project is something that creates a unique product, result or service. Furthermore a project is something temporary, which is granted with a beginning and an end, so it is basically meant to die. However an operation is something that continuously gives support and can be foreseen as something not intended to die [1].

Managing projects is something that requires structure in order to have the best rate of success. By not having any structure there is a severe risk of achieving projects where the different tasks will start to work against each other, which could result in requirements from the stakeholders not being meet, bad communication and collaboration among the involved parties. Furthermore the time schedule and budget might have to be extended. Lacking or missing structure is therefore a project manager's worst nightmare and must be avoided. The best way to achieve such order from the very start is to apply some kind of management process to assure that the project is steered and kept in the right direction. Among the many tools available the project scope management[1] could be chosen. When working through a management process like this, the covered areas will be: Plane scope management, Collect Requirements, Define Scope, Create WBS "Work breakdown structure", Validate Scope and Control Scope[1]. Within the project scope management process, the creation of a WBS "Work breakdown structure" is a tool, which has some large benefits in order to obtain a good cost-, time planning and execution of the project. There are different types of "breakdown structures", determined by the given approach. In this article the focus will be on the PBS "Product breakdown structure", which implies: History, description, application and limitations in relation to project management.

The outcome of a project can be referred to as a product. The PBS tool is applied to identify "name/number" all the sub products that contributes the to final end product. In this way the PBS tool is applied to make large and complex products more simple to handle. Within the last 50 years the value added pr. work hour increased by 250% in manufacturing, but in construction the value added pr. work hour has been maintained[2]. The currently state of the art when it comes to construction, is the industrialized construction e.g. prefabricated elements, meaning a possibility of continuity and mass production. The PBS tool is thought to benefit this new way of construction, through product simplification and cost estimation.

Contents |

Product breakdown structure "PBS"

History

PBS

The historical creation of the PBS is unknown. However it is known that PBS is a tool, that contributes to the Work breakdown structure, which were invented by The United States Department of Defense (DOD) back in 1960's[3]. The tool were finally implemented in the PMI "Project Management Institute" PMBOK in the 1987 as a standardized tool[3]. The Product breakdown structure tool is wisely applied, when having a production line with many sub products. Thinking of a car, this is a final product assembled from a lot of sub products. The product breakdown structure can be used to create an organized hierarchic illustration of the car.

Construction

In order to compete, companies continuously seek new ways to make things more effectively and efficiently. Research has proved that implementation of new technology, within the last 50 years, has caused the value added pr. work hour to increase by 250% in manufacturing, but in construction the value added pr. work hour has been maintained[2]. Many fingers can be pointed when making a statement like this. Many organizations has tried to figure out what has been causing this problem of stagnation, and some of the issues so far has been pointed out to be, that all projects are unique. The reason is, that unique projects causes a need of e.g. unique technical, solutions and production methods[2]. It seems that there is room for improvement in the profession of construction. One of the suggested solutions is the concept of continuity and mass production, combined with as much flexibility as possible, which has been known to benefit the business of manufacturing.

Why is Product Breakdown Structure important in construction

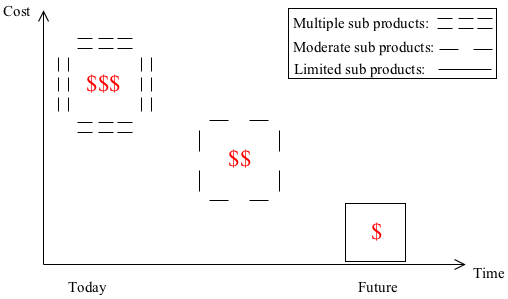

The currently state of the art when it comes to construction, is the industrialized construction e.g. prefabricated elements, meaning a possibility of continuity and mass production. The elements are a sub product and the many elements are assembled on site. The industrialized construction approach makes it possible to reduce the human factor, which tends to be a significant contributor to the cost related uncertainty. With this approach the benefit of making a product breakdown structure in a construction process, can now take its place. At figure 1 below, the "old" well known construction trend is illustrated. It is consisting of many sub products, which depend on human resources in order to be assembled. Notice that each square is illustrated by one or several lines. The reason were to give an illustration of the futures reduction of elements in construction. A rule of thumb in the "current" construction is, that the ratio between human labor and the material are approximately 2/3, so the human factor plays a big part of the whole project. When moving towards the future it is illustrated that the assembly will depend less on human resources and more on prefabricated products. However the products will still need production e.g. the concrete wall. The main focus upon the approach is that the e.g. concrete wall could be produced externally under known "steady" conditions, which minimizes the cost deviation, because the sub products are part of a well-planned production line. As previously mentioned the PBS is a tool, which contributes to the WBS. In the future it is estimated that the PBS would play an increased role of the WBS, because of the possibilities of making the prefabrications.

Please note that the cost is only focusing upon the expense for the human labor on site. Even if the whole project would end up with the same project price, the industrialized construction technology would still be the one with the smallest uncertainty. The reason is that the product breakdown structure makes it easy to predict and illustrate the cost for each sub product, because a manufacture can give a specific price for each sub product.

Moving further to exactly why the PBS is such a great tool to be applied to construction projects. As mentioned it can be hard to predict costs, divide and organize the many products on a construction site. The PBS is an available tool that can be applied to organize the future construction site, which according to the industrialized construction would be based on prefabricated sub products. When having a construction project the exact cost of the deliveries is often not known at the initial phase of the project. However it would still before the bidding rounds be possible to make the breakdown structure, based on experience and judgement. After the bidding rounds the costs of the delivered products can be known and can be applied to the PBS. This approach is known as the rolling wave planning[1]. A well-organized PBS can also help the project manager as an "assembly manual" to organize the logistics of the construction site, so the deliveries on site matches assembling process. The WBS will still be needed in order to make the time schedule, since this is not included in the PBS. According to the similarity in construction sites it is important to save the PBS file after each project, so a portfolio of templates can be build. In this way the project managers might save some time in the future.

Application

Performing the breakdown structure

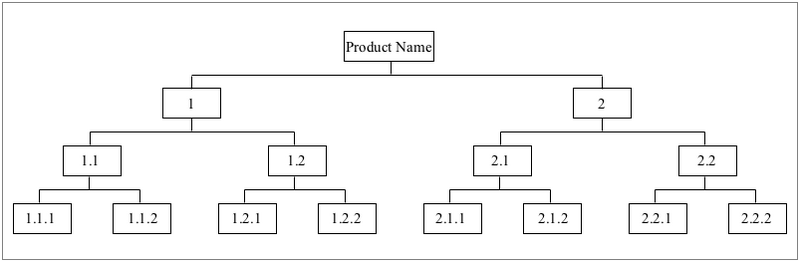

The technique applied for dividing and subdividing the delivered product into smaller bits is decomposition[4]. It is advised that the decomposition are made by setting up a group of competent people, since this often requires multiple insight perspectives. The main reason for the breakdown structure is to take something largely complex and break in down into smaller bits, in order to make it more simple to handle. The breakdown process should be made in a way, such as the size of the current product "box" makes sense. When it comes to prefabricated elements, it would make sense at least not to breakdown any more than the delivered product. Based on the desired complexity of the PBS, the product decomposition can also be made in relation to the deliverables. If the project is supposed to be inspected in milestones, then it would be preferable that the PBS would be divided into matching the project milestones. Performing the PBS can either be done by the top-down or bottom-up approach, according to what the project manager finds to be the most convenient[4]. When having large and complex products, it is advised to use a numbering system in stead of only using names, because this approach can easily result in proliferation of names[5].

Making the PBS diagram

Figure 2 below illustrates the hierarchy of the PBS diagram. In order to create even more overview of the product, it is also possible to colorize the different boxes, so they could refer to e.g. a project milestone.

Furthermore there are invented some checkmarks[6] [4], which can be beneficial to keep in mind when making the PBS.

1) Define the product and the related technical requirements.

2) The top box should always represent the final product.

3) When making the decomposition "top down or bottom up", do not make more boxes than needed in order to sustain a suitable overview.

4) Depending on the product size, consider assigning each box with logical name or/and a number.

5) Remember that the PBS only focuses on the product, not the work related to the project (WBS).

6) The product description be a beneficial reference point, when making the diagram.

Example

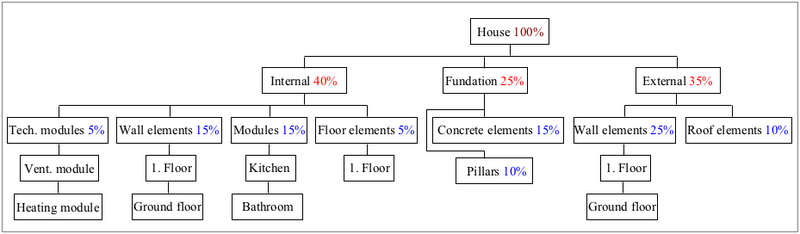

Figure 3 below illustrates how the diagram can be applied, when making a PBS for a one family house. Also note that the different boxes have been assigned with a percentage, which refers to how much the given product poses of the end product "The house". Colorization has been added to the percentage indication. This has been done to create an illustration of the product and sub product structure. In industrialized construction of hospitals and hotels and larger compartments, a bathroom has been proven to be delivered as one whole product "module" on site, which has been taken into consideration when making the PBS example.

Digital tools

Amoung the many available tools on the market, a software called MindView has been chosen. The youtube video has been developed by the company MatchWare[7] and they manage to give a brief introduction of the software.

Unfortunately the youtube video is focusing on making a WBS. Even though the video shows a lot of features that the program are capable of. Among the many features, the program enables the user to change the structure of the breakdown structure e.g. change from top-down to left-side view and summarize the costs of sub products. Furthermore the software is compatible with Microsoft office programs such as; Word, Excel, Powerpoint etc.. When managing projects with digital tools it is important that the persons involved in the project has the option of instantaneously getting the resent updated files e.g. PBS, OBS, WBS,time plan, budget. Under the assumption that almost all professional companies has a Microsoft work package, this program can be applied.

Dictionary

For large product trees there can be hundreds or thousands of unique sub products[5]. Therefore it is important to consider how the different boxes is referred to. When having small logical products, it might be sufficient by using the logical sub products names for the given boxes. Considering the large products, it is hard to name each box without matching some existing names. Therefore it is advised to use a numbering system instead. In this way it is still possible to name the different boxes, but the uniqueness of the given product is linked to its number. When using a system like this it is beneficial to have a description/dictionary of each product box in a separate document. The dictionary can also include a document where the project managers approval is needed, when starting up with a new task. In this way the constructors can get the knowledge of which boxes, that has to be initiated before others, so these will not conflict with each other.

Applying the PBS diagram to cost overview

Under the assumption that the future is industrialized construction, the PBS is assumed to be a large part of the cost analyze. Due to construction similarities each new site could more or less have the same PBS template, therefore a cost estimation can easily be made. Among the many different techniques for this process the Three-point estimating[1] process can be applied.

The three-point estimation is about gathering three different prices form the PBS example. This could be e.g. a kitchen module. The three prices are based on three approaches being: Pessimistic (P), Most likely (M) and optimistic (O).

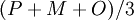

According to the three prices the following equations can be applied in order to calculate a "simple average" and a "weighted average".

Triangular distribution "Simple average"[1].

Beta distribution "Weighted average"[1].

If desired the standard deviation of the Beta distribution is calculated by using the following equation[1].

The obtained prices can now be added to give a estimation of the percentage applied to each product and sub product.

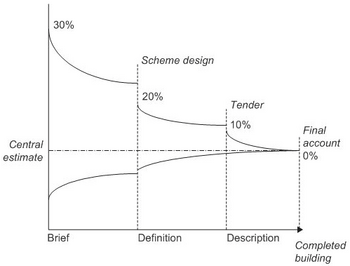

Graham Winch elaborates on the use of the "three point estimate" and he also manages to give an illustration of the cost uncertainties related to a project. The given illustration is shown as figure 4 below.

Based on figure 4 it is obvious that the three point estimate is a great tool to use as a cost estimator. The figure also shows that if a cost estimation is repeated later in the project the cost uncertainty is reduced. Therefore the PBS should be continuously updated, because the given project phase matters when making the "three point estimate".

Limitations

Even though the PBS is a very powerful tool it still has its limitations. The quality of the PBS depends a lot on competences of the team making the decomposition of the end product. Therefore it is extremely important that the team contains a large range of competences, in order to obtain the multiple perspectives. Furthermore it could be questionable that the stakeholders would accept to pay the large amount, that it requires to assemble the required team.

The PBS is focusing on the product, while the WBS is focusing on the product and the work related with it. Furthermore the Organization Breakdown structure "OBS" is created to divide the responsibility according to the execution of the given tasks. Therefore the PBS is, from at an project management point of view, not complete, even though a lot of knowledge can be gathered by using it.

The PBS is depended on its inputs. In the case of using the project scope management approach the input are: Plane scope management, Collect Requirements, Define Scope. Based on experience it is known that these inputs are likely to change during the lifetime of the project.

The PBS does only include the components related to the final product and not the ones related to preparations or temporary tasks [8]. Regrading to the amount of necessary preparations or temporary tasks related to the project this makes a uncertainty.

Annotated bibliography

When gathering information about the subject "product breakdown structure", the information seems limited compared to the available information related to the work breakdown structure. The reason is that the work breakdown structure is the "mother" to the other breakdown structures. However the overall approach is more or less the same, and the product breakdown structure is a matter of turning the focus into primarily focusing on, the decomposition of the product. The chosen literatures have been educational books combined with relevant articles and webpages. The choice of the used material is now elaborated.

Books

- Graham M. Winch (2010) ”Managing construction projects”, Wiley-Blackwell, Second Edition.

The book provides the reader a broad understanding of project management, including some case studies, were the given approach has been applied. Graham M. Winch book ”Managing construction projects” is a acknowledged book, and therefore useful when writing a article.

- Project Management Institute (2013) ”A Guide to the project management body of knowledge (PMBOK Guide)”, Project Management Institute, Inc., Fifth Edition.

This book is published by the PMI "Project Management Institute" as teaching material to their project management exam. The book are therefore foreseen as acknowledged teaching material for advanced project management and have been very useful, when digging into a specific subject, such as breakdown structure.

- Rita Mulcahy, PMP, et al. (2013) ”Rita Mulcahy’s PMP exam prep”, RMC publications,Inc., Eigth Edition.

This book is published by the Rita Mulcahy as teaching material. The book has been made as a guide to understand the PMBOK Guide, in order to pass the PMI project manager exam. The book are therefore foreseen as acknowledged teaching material for advanced project management and have been very useful, when digging into a specific subject, such as breakdown structure.

Articles

- Lamers, M., Do you manage a project, or what? A reply to "Do you manage work, deliverables or resources", International Journal of Project Management, April 2000, DOI:10.1016/S0263-7863(00)00053-3

The article reflects upon project management and the usage of WBS, OBS and PBS. The article gives a basic understanding of the tools and their purpose and how to separate them.

Webpages

- www.productbreakdownstructure.com [2], visited 12-06-2017

The homepage briefly introduces PBS and provides the reader with some good examples.

- Industrilized construction forum [3], visited 12-06-2017

The pdf-file collected from this website provides a general understanding of the concept of Industrialized construction.

- www.smartsheet.com [4], visited 12-06-2017

This homepage provides the a broad understanding of the work breakdown structure, which to some extend can be beneficial when working with product breakdown structure.

- www.matchware.com [5], visited 21-06-2017

The homepage provides the information of the digital software Mindview and the features their software enables.

References

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 Mulcahy, Rita. (2013), Rita Mulcahy’s PMP exam prep, RMC publications,Inc., Eigth Edition.

- ↑ 2.0 2.1 2.2 Industrilized construction forum [1]

- ↑ 3.0 3.1 https://www.smartsheet.com/getting-started-work-breakdown-structures-wbs

- ↑ 4.0 4.1 4.2 Project Management Institute, Inc., A Guide to the project management body of knowledge (PMBOK Guide), Project Management Institute, Inc., Fifth Edition.

- ↑ 5.0 5.1 Do you manage a project, or what? A reply to "Do you manage work, deliverables or resources", International Journal of Project Management, April 2000, DOI:10.1016/S0263-7863(00)00053-3]

- ↑ www.productbreakdownstructure.com

- ↑ 7.0 7.1 https://www.matchware.com/wbs-software

- ↑ 8.0 8.1 Winch, Graham M. (2015), Managing Construction Projects, Wiley-Blackwell.