Implementation of BIM as communication tool for construction site operations

Abstract

There is an ongoing interest in the possibilities for innovations which Building Information Models (BIM) can offer in improving building design and management[1]. This topic has the last couple of years been addressed in many publications and established its name in both the scientific world as on the building site. Both research and practice have proven the potential BIM has in the Architecture, Engineering and Construction (AEC) industry. However, until recently the focus has only been on implementing BIM in the design phase and in higher management level during construction. The area which hardly has been covered is implementing BIM on the construction site. On the construction site BIM could replace current outdated communication processes, prevent construction errors and enhance the quality of current management tools. In addition, the implementation of BIM could offer more insights into processes on the building site for future innovation and research.

Contents |

Introduction

Applying BIM on the construction site offers the potential to replace the uniform paper-based drawings which are currently delivered at the start of the construction phase. The problem with these current drawings is that they have to provide information to all disciplines present on the construction site and are often outdated [1] . The fact that these drawings are outdated also undermines a great deal of the benefits of BIM on management level. The new application of BIM which is proposed for the construction site makes use of an up to date BIM-server which can be consulted at any time by the project operator. The project operator is the responsible person on the building site to coordinate and inform the craftsmen. He gets on his turn information from the contractor and suppliers. The project operator can with BIM not only offer up to date information but can also easily extract relevant information for the craftsmen on sight.

This article will give insights into the possibility to use Building Information Models (BIM) on the construction site as communication and management tool. First the current situation of the industry and the level of implementation of BIM will be discussed in order to provide some background information. After this chapter, the levels of implementation and coherent benefits will be explained in more detail. This will be followed by a more critical overview of the challenges, barriers and opportunities

The Architecture, Engineering and Construction (AEC) industry is an industry which identifies itself by being conservative and has seen few innovations during the last decades. In contrast with most other industries which have shown to be more progressive and have managed to increase their efficiency substantially [3]. However the transition in the AEC industry from 2D designing towards a more integral collaboration working in 3D models offers a great perspective [4] [5]. These digital solutions enable the growth of building complexity to be properly managed and offer the possibility to increase efficiency within the industry.

“BIM is a business process for generating and leveraging building data to design, construct and operate the building during its lifecycle. BIM allows all stakeholders to have access to the same information at the same time through interoperability between technology platforms.” [6].

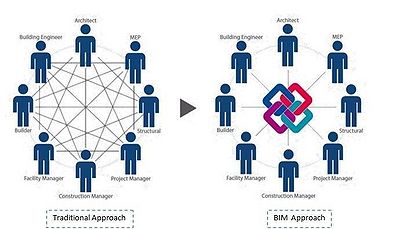

BIM increases productivity within the AEC industry by functioning as a communication, management and information tool. The difference in approach between the traditional and new approach is visible in figure 1. Through the implementation of one central server through which all stakeholders can communicate a large increase of efficiency is achieved. Whereas traditionally everyone communicated directly to each other resulting in rumors and errors by repeating of information, now all information is gathered in the BIM and made available for all stakeholders. This offers the possibility for a more integrated design process and to check the model fit of the different disciplines. In addition design flaws can be detected in a pre-built phase which reduces a substantial amount of costs during construction. However BIM offers many more opportunities to innovate within the AEC industry. One of these opportunities which is until now only scarcely adopted is the use of BIM on the construction site for operations.

BIM in the AEC industry

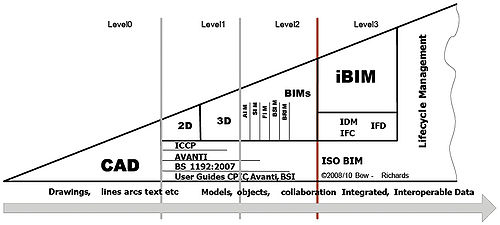

The potential of BIM is not yet fully exploited by the entire industry, large gains in efficiency are still to be made. However large progress has been made as can been seen in figure 2. The industry came from 2d working in Cad programs to now level two and three in which BIM is more and more integrated and used to optimize to design, construction and management of buildings. One of the gains which is not yet widely adopted is the implementation of BIM on the construction site. On the construction site, BIM could replace the uniform paper-based drawings which are currently delivered at the start of the construction phase. These drawings form the largest part of the communication between the contractor and the project operator on site. Despite that the drawings have been often extracted from a BIM, they are not adequate as communication means [1]. This is mainly due to the fact that from the BIM uniform drawings are generated to be used by all different disciplines. A few decades ago that would not cause any problems, however with the growing number of different disciplines and the complexity of buildings these papers are not sufficient anymore. In addition one of the core principles of BIM is undermined by extracting drawings for a longer period of time from the model. This is because after extraction these papers can only be manually updated, which causes confusion and errors.

BIM on the construction site

Using BIM on the construction site can be done in various ways which will be discussed in the chapter Levels of implementation of BIM. What all these ways have in common is that they intend to provide actual, specific and precise information to the workers on the construction site. The person who needs to provide this information in the form of drawings and verbal communication is the project operator. He will be in charge of extracting relevant information for each group of workers shortly before workers need to execute the task. Extracting relevant information can be made easy for the project operator by labeling elements in the 3D model to specific disciplines. The project operator needs to switch on relevant layers in the model and generate floor plans, elevations or sections from the required part of the design. In addition he has to option to add relevant product or construction information. The initial generation and communication will require more time from the project operator. However this is time which is earned back by a reduction of question about the drawings and a reduction of problems needed to be solved. Another benefit is that he can monitor the progress of the construction more accurate by clearly defined tasks which can be indicated by the workers as finished. The overview of the progress indicated in BIM is also insightful for others stakeholders.

Level of implementation of BIM

Taken into account that the AEC-industry is rather conservative different ways of implementation of BIM have been developed. From other implementations of BIM had been learned that it requires large behavioral changes from the employees who have been doing their job sometimes for decades in the traditional way. Therefore generally a gradual approach of implementation is preferred, however there have been exceptions.

Here an option for the more gradual approach will be discussed, based on insights from current case studies[8][9]. The first step is to change from a large archive of drawings and documentation to a more on-demand generation of drawings. These drawings are still printed on paper however deliver slightly different information than the traditional drawings. As these drawings are task-specific one A3 paper can contain multiple views both 2D and 3D and additional information. The clarity of these drawings is enhanced by removing redundant information from the drawings. These A3 papers contain information which previously had to be extracted from multiple larger drawings and does not contain scribbles of changes. For this level of implementation, the project operator will hand over the information and will keep track of the progress. This step is the upgrade of the communication between the contractor and the project operator. As the contractor will now communicate not through paper anymore but by means of the BIM-server. The project operator will need to be educated in working with BIM and extracting information from it and important is that the contractor on his part ensures all required information is available.

The second level of implementation requires a higher level of digitalization. The workers are provided with tablets in which a more dynamic overview is given of the required tasks. This is an intermediate step and has only a small influence on the efficiency by directly being able to notify the progress of tasks in BIM. Here the focus is on establishing a new form of communication between the craftsmen and the project operator. The project operator is helped by this step in the sense that he has to spend less time on composing the paper drawings. Instead, he can send drawings in which the workers can zoom in and out.

The desired level of implementation which requires the largest behavioral change of the workers on site requires communication through the digital means. Workers will be provided with the BIM model in which they have certain rights for input. Within the tasks, they have to perform they can report flaws, missing materials and other comments. These notifications will alarm not only the project leader but also the responsible stakeholders. At that moment BIM will really introduce itself as a communication device. Every stakeholder can access the BIM model and problems can easily be discussed due to detailed information about the materials/products and the implementation of these parts.

Challenges & Opportunities

The replacement of the traditional papers on itself by access and interaction with a BIM can increase productivity substantially. However, there are also spinoff effects. The implementation of BIM on the construction site creates a communication line between the actual workers and the people who design and plan the projects. Despite that there will not always directly be a direct reaction from these parties, it does give them an opportunity to reflect on the progress. Also, valuable data can be gathered which is more accurate than previously. This data contains information about the likelihood of risks, task requirements and required time necessary to finish tasks. The project manager can reflect on the speed and quality with which the communicated data is perceived and applied. Which enables him to communicate even more efficient with his employees.

The intention of BIM tools initially has been to use it for its design features and the possibility to visualize the project with renders and video clips for the client [10]. Contractor and project operators have different requirements in information which needs to be collected in BIM. These changes have partially already adopted by other disciplines who added parts of this more specific information. However, the designers will have to implement even more detailed information or enable others to do so. This is an iterative process which will require some time and training of the different disciplines. In addition researchers and students is asked to expand the current tool base and standards.

A big part of communication on the construction site has as biggest challenges still the change management [10]. Despite that there is much more information available through BIM and insights into errors and planning, there are always last minute changes. These changes can be either be created through the client, material shortages, unavailable staff and the weather. In the previous situation, only the contractor would be aware of these changes and he has control over which changes are shared with specific stakeholders. The difficulty which now arises is that all stakeholders can monitor these changes however small they are. This makes other stakeholders feel more in control and gives them the possibility to give their opinion about these changes. However legally not all of them or even none have rights to change the design. This can lead to frustration of parties involved in the change, which have to be even better managed in contracts.

Conclusion

The AEC-industry is well on their way in innovating their sector and gain productivity. Now BIM is on the verge of being implemented on the construction site. Currently, the tools to radically change communication on the construction site between the craftsmen, project operator and contractor have been developed. However, there is still an ongoing iteration of these tools and research into how these tools can be best introduced into this sector. Already proven is that productivity can be increased and the required budget can be reduced, in combination with the ability to deliver a better-documented building with fewer errors this gives a strong value proposition.

Key references

(Berlo, 2016) This article gives an overview of the theory of BIM and the implementation in the construction site with the possible advantages. Furthermore, it proposes a case study in which this theory is applied and a communication option is proposed. The proposition in the article is that the project operator generates A3 overviews with drawings and additional information, to be used by the craftsmen.

(Bargstädt, 2015) This article reviews the possibilities and challenges of implementing BIM as a tool on the construction site. The focus is on the current status and knowledge about BIM and how to proceed in these field in order to keep moving forward to an optimum use of BIM.

References

- ↑ 1.0 1.1 1.2 Berlo L. A.H.M., Natrop M. (2015) BIM ON THE CONSTRUCTION SITE: PROVIDING HIDDEN INFORMATION ON TASK SPECIFIC DRAWINGS, ITcon, Vol. 20, 97, ISSN 1874-4753

- ↑ Hattab M., Hamzeh F., (2013) INFORMATION FLOW COMPARISON BETWEEN TRADITIONAL AND BIM-BASED PROJECTS IN THE DESIGN PHASE, Proceedings IGLC-21, July 2013, Fortaleza, Brazil, Retrieved from: https://iglcstorage.blob.core.windows.net/papers/attachment-46735d29-ae2f-4edd-bb40-bd1a26da309c.pdf

- ↑ Vestergaard. 2017. 02_Intro_ØG-DDB_11034_2017. Advanced Building Information Modeling (BIM). DTU Lyngby. Retrieved on: 14-09-2017. Retrieved from: https://cn.inside.dtu.dk/cnnet/filesharing/Overview.aspx?FolderId=1084089&ElementId=551783

- ↑ Singh V., Gu, N., Wang, X. (2011). A theoretical framework of a BIM-based multi-disciplinary collaboration platform. Elsevier. Automation in construction 20. p. 134-144.

- ↑ BIR, Bouw Informatieraad. (2016).BIR Kenniskaart nr. 5. BIM transitie in organisaties. Retrieved from: www.bouwinformatieraad.nl on March 10 2017.

- ↑ BuildingSMART. (2012). Technical vision: openBIM. Retrieved September 10, 2015, from http://www.buildingsmart.org/standards/technical-vision/

- ↑ Cutler J., (2016) Future cities, smart cities and building information modeling, BIM is not CAD, Retrieved from: https://www.geospatialworld.net/article/future-cities-smart-cities-bim/

- ↑ Kimotot et all., (2005) The application of PDA as mobile computing system on construction management, Elsevier, Automation in Construction 14 (2005) pp500 – 511, doi:10.1016/j.autcon.2004.09.003

- ↑ Davies R., Harty C. (2013) Implementing ‘Site BIM’: A case study of ICT innovation on a large hospital project, Elsevier, Automation in Construction, 30 (2013), 15–24, Retrieved from: http://dx.doi.org/10.1016/j.autcon.2012.11.024

- ↑ 10.0 10.1 Bargstädt H. J. (2015) Challenges of BIM for Construction Site Operations, Elsivier, International Scientific Conference Urban Civil Engineering and Municipal Facilities, Germany, 117, pp 52 – 59