SWOT analysis for Prefabrication Housing Production

Contents |

Introduction

The article focuses on the SWOT analysis application to the prefabrication housing production. SWOT analysis could be used in profit seeking organizations and in decision making situation. the purpose of this article, is to explain how to apply the SWOT matrix tool, to management of prefabricated house.Furthermore, the Prefabricated Housing Process is explained, with all the innovations and benefits, which this production method has brought into the estate market.

In the past years, the most common method of building housing was the on-site method. The construction process starts with a project, which is developed by professionals and requires a certain amount of time to be completed. Once the final project is obtained and approved, is it possible to start with the building phase. The process required the set up of a construction site, which costs time and a large amount of money. The following phase is the construction operated on site, which is exposed to various risks that can be generated by the site environment, or from unpredictable events. The manpower cost is higher, because it must be highly specialized, and it has to adapt its knowledge depending on the site and the project.

Another significant economic impact on the buildings cost is generated by the transport of materials and the mechanical vehicles, needed in the construction process. With the advance of technology and the expansion of knowledge, many companies have finalized to the conclusion that the process of houses prefabrication is more efficient than the on-site construction.

Finally, tools like the SWOT analysis are simpler to apply to prefabricated constructions, because they have more similarities to industrial processes.

SWOT analysis

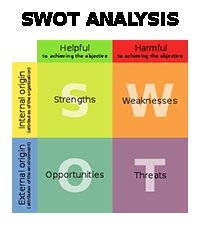

SWOT analysis is a strategic planning method, to assist companies identify advantages and disadvantages related to business aspects or project planning. This technique is applied through the use of a SWOT matrix which explains strengths, weaknesses, opportunities and threats of the project. SWOT is also described as a management tool, to develop strategic analysis. This tool helps to specify the internal and external factors, that are favorable and unfavorable to achieve all the project targets. Users of a SWOT matrix, need to create useful information, to make the tool able to explains their possibilities. The word SWOT is an acronym for the four parameters which the matrix examines:

- Strengths: qualities of the business project which are helpful to achieve all the stated objectives.

- Weaknesses: business harmful possibilities, which place the project at a disadvantage relative to other similar projects.

- Opportunities: market elements which could help the business project to success compared to others.

- Threats: all the factors which could cause trouble to the business project

Using the SWOT analysis tool, is it possible to identify all the internal and external factors, in a business project. In this way, SWOT analysis collects key information in two different groups:

- Internal Factors: which are strengths and weaknesses inside the company. They effect on the company's project, including also personnel, manufacturing and economy.

- External Factors: namely opportunities and threats presented in the environment, external to the company. They can include more general aspects such as legislation, social and technological changes.

Identification of SWOT matrix is useful because it helps to inform later phases if the objective is achievable. After applying a SWOT analysis on a business project, decisione makers should understand if the goal is attainable or not. In case that the goal is not achievable, Decision makers must select another goal and repeat all the process again.

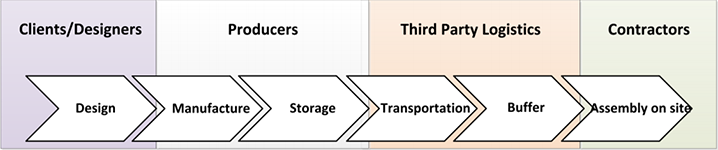

House Prefabrication Process

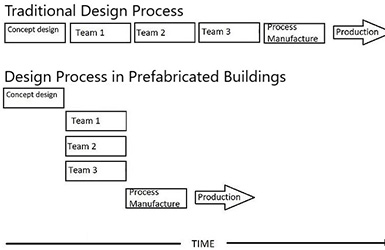

The Prefabricated Process is a high performance method, that highly increases the efficiency in building production. During the process of prefabricated home, the design is done in collaboration between different partners, who have to develop their products using factory prefabrication methods. This is a total new concept in the building design. Despite the fact that researches and new instruments have been applied in this emerging industry, most of them need to be further improved. The various experiences developed over the years show that, It is a process where the different design teams (for example: structural engineers, architect, Building Services engineers, etc.) work closely in order to adapt the prefabrication process to a whole building. The design aspects are developed to raise quality and performance as possible. The Prefabrication Process increase in efficiency, both in economic and temporal terms. For all these reasons, is it possible to say that, the building business is moving to new frontiers, namely: Prefabrication.

Companies, are researching different methods to further develop the concept of prefabrication. One of the most efficient methods, is based on prefabrication of building parts, but imagining them as small parts, which would later form a larger element. Each of these individual parts must be designed and built in the factory. When the all process is completed, the finished product, will be an whole house, which has been assembled with the same production process that is used today in the automotive industry. Starting from this concept, this article explains how to apply to the industry of prefabricated houses, the production managing system and the SWOT tool, used in automated factories. This is a hard concept, both to understand and to improve, because is not common in the building industry. Despite the various complications that can arise, producing prefabricated houses with the same industrial process used in the automotive industry, could be an example of innovative vision. There are already numerous prefabricated projects on the market, carried out by important industries in the sector. These companies are responsible for providing the customer with a complete home, built according to needs and requests. Therefore, for each individual project, the company will have to adapt its production each time according to the guidelines received. An innovative idea is to allow companies to mass-produce their own prefabricated houses. Once completed an exhaustive portfolio, customers will have to adapt their requests, depending on the products provided by the company. At the end of the process, the final product will be the finished home, ready to use. Even thought customers can customize their home according to their needs, companies will not need to adapt their tools for each building, so it could use every time the same production line. This method create a double advantage for both the customer and the company.

Tool application - Danish Construction industry

An environment, where could be interesting to apply the SWOT matrix tool, is the Danish market of prefabricated buildings. Considering the Danish construction industry as example, a range of figures have called attention for improvement of competitiveness. In contemplating various initiatives to develop the industry’s practices, increased industrialization is currently receiving considerable attention throw efficiency to the potential benefit of both customers and the stakeholders carrying out construction work. Industrialization can find expression in among other things the factory-like production of system products to be implemented in buildings. These products have a certain appeal because they employ modular architectures which enable suppliers to achieve production wise advantages while also offering customers some variety and customization through individual configuration of the elements forming the products. This ongoing effort suggests that supplying system products to the construction industry and implementing them in building construction projects is not a straightforward matter; it may be associated with considerable managerial and practical challenges. Danish market uses the system product, which is a multi-technological complex part of a building, developed as a completed modular and variable product. The system is developed in a separate product development process based on the principles of integrated product "development for life cycle", which means preparation of its marketing, delivery process and servicing. "The system product is developed for mass customization and it is developed with a room for variation within which it can be configured and individualized for each construction work." [1].

Potential Applications

[2] In the research for a specific and real application, it would be interesting to apply the tool described in this article, to a company. This would be a practical way to use SWOT analysis. At the same time, the company would receive helpful information, because it could easily evaluate its elements within the SWOT matrix. A possible application could be on "ScandiByg", which is the danish market leader in the field of industrially manufactured construction. The company is specialists in the development, production and construction of modular buildings. Scandybig has over 40 years of product development, their expertise enables to design solutions that match the individual customer's wishes and requirements for a building project. The company's primary business area is construction of housing, offices, and institutions with prefabricated element, for professional private and public customers. The organization has a long history of manufacturing solutions for other purposes than construction work. After years of developments, the results of the company were the introduction of various concept. From this concepts a number of products were developed. These products are managed by a team of employees based in the Danish headquarter, who manage the administration, product and project portfolio and sale, and sales agents abroad take care of sale to foreign markets. Examples of system products are integrated façade solutions, garrets, prefabricated kitchens, bathrooms and multi functional ceiling solutions. This definition builds on an understanding of “modularity” as the development of modules employing some common characteristics which can be varied in order to meet customers’ needs. The decomposition of products and the standardization of components’[3] interfaces is what theoretically enables modularity to ensure such individual solutions . Integrated product development means that developers make decisions which have consequences in the rest of the product’s life cycle. They therefore attempt to create a product which is appropriate in configuration, use and maintenance. Finally, the term “mass customization”, expresses an intent similar to modularity, namely to develop a product program which matches different customers’ different needs and doing it in a cost-effective way by ensuring some common features in construction, production and installation.

SWOT Analysis Application

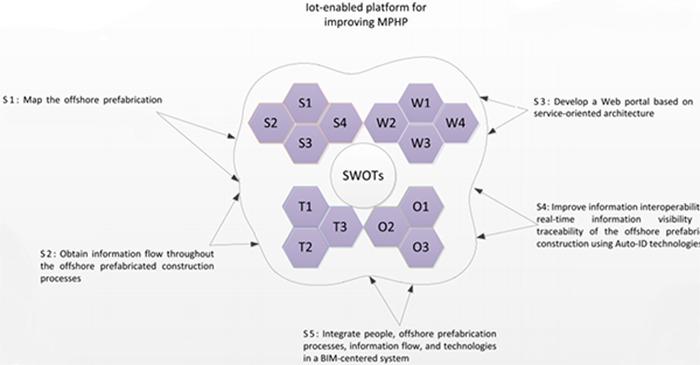

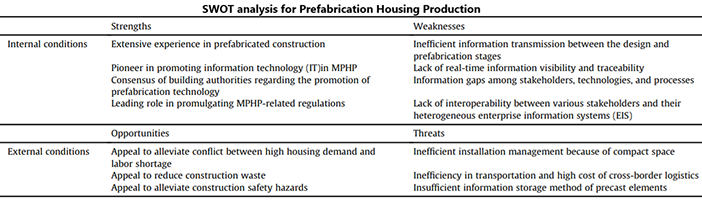

This chapter explains hot to apply the SWOT analysis tool to the Management of Prefabrication Housing Production (MPHP). SWOT analysys approach, is the most crucial tool adopted for the strategic analyses of MPHP. It is useful, especially for the strategic planning process. The tool is recognized extensively and constitutes an important means for learning about a situation and designing future procedures that can be considered necessary to enable strategic thinking. The methodology adopted in the study of MPHP is articulated in a step by step process. The first step is to confront the current housing challenges with a detailed analysis of collected documents. These documents, are collected from two different sources: market investigations and reports by consulting stakeholders involved in building production. The second step, is research through questions, in order to investigate the SWOT of prefabrication housing production. Mainly questions are related with information on the benefits that result from MPHP development, including improved quality, shorter construction period, and better construction environment. The results, from the research, are obtained from a series of structured interviews with major stakeholders, manager from precast manufactures, logistic companies and engineers. Although the opinions of other stakeholders, may benefit the understanding of practical construction problems in the precast housing production process, their ideas could reflect problems from a project-level, rather than from a general perspective. Third, based on the identified SWOTs, suggestions to improve the prefabrication housing production are proposed in accordance with the principle of transforming weaknesses to strengths, and minimizing threats. SWOT analysis enables the identification of the main problem, confronting the construction industry which uses prefabrication technologies and contributing to the formation of a better understanding of both the internal and external situation of MPHP practice. The external conditions are related to the threats and opportunities, whereas the internal conditions refer to the weaknesses and strengths. This is a specific result on SWOTs study on prefabricated buildings.

Strenghts: wide experience in prefabricated construction

Prefabricated construction has long been adopted in Australia, USA and northern Europe. This new construction method were first developed in the 1980s, since this period, prefabrication and standard modular designs, were introduced in public housing projects. The most frequently adopted precast elements include: parapets, precast facades, partition walls, semi-precast slabs,staircases, kitchens and precast bathrooms. Today, after 30 years, sufficient knowledge is achieved in this field.

Weaknesses: problems between design and prefabrication stages

the method of considering the prefabrication features in the building information modeling (BIM) process and transmission of the design information to the manufacturers are unclear. Ideally, technical drawings of the construction components (e.g., slabs, partitioning walls, staircases, etc.) should be generated directly from the BIM model to the manufacturers who will produce them accordingly. Manual handling of ordering information is extremely difficult. Similar to electronics companies, a manufacturer commonly supplies various prefabrication components to different clients and their construction sites. Receiving orders and changes from the clients would cause the production to become full of errors.

Opportunities: reduce the housing demand

Almost every metropolitan city in the world, has housing problems, related with the mass concentration of people in small areas. As a consequence,the price of rent has risen considerably, creating a situation in which citizens cannot afford an adequate accommodation. Using the prefabrication process, governments could have the opportunity to supply sufficient dwellings and solve overpopulation problem.

Threats: inefficient installation management

Construction sites are often restricted within limited spaces for storing large and heavy components. Therefore, site management is often the critical path for the success or failure of a construction project. Under these circumstances, a BIM delivery and assembly model could be a interesting solution to prevent problems. The limited space results in more time for vertical transportation of precast units from the ground level to the designated floors. Verification of the components is also inefficient because of the extensive use of paper or paint labels. Workers have to pay attention to the verification process, leading to extra labor and time costs. Despite the focus of workers, accuracy of the verification process is not guaranteed because sometimes paper-based documents are unclear. Current practice may also cause safety issues. Finally, Construction workers on the sites are often preoccupied with their responsibilities and knowledge.

Advantages of the House Prefabrication Process

Theoretical advantages [4] of pursuing modular product architectures have already been elaborated extensively, and they have been documented [5] in specific product contexts, particularly in the area of personal computers . The advantages of modularity include the achievement of scale economies while meeting various requests, a reduced need of managerial coordination, facilitation of innovation and development to meet changing market conditions as well as clarification of organizational knowledge. Research on modularity also includes a continuous investigation of the further potentials and limits associated with modular product architectures. This trend has led researchers to explore the relations between modularity and a variety of managerial concerns [6] such as organizational knowledge, coordination , supply chains and the ability to develop or alter product components [7] and architectures. The focus of this chapter is to provide the insight, that modular product architectures bring into the building industry. The topic of modularity as a strategic and practical tool, related with the SWOT analysis, is difficult to implement. In prefabricated constructions, a balance between systematization and standardization must be found. Furthermore, architectural variety and innovation, always needs to be defined because “standardization is a key concept in modularization“ [8] .

Practical advantages of using prefabrication are mainly related with economic benefits. Companies can save large amounts of money by applying a mass production process, avoiding changing in the production methods of every single project. This methodology is atypical in the construction industry, but it could rise various improvements. Modular homes have many advantages including:

- Strong structure: modules that make up a building are more durable than those built traditionally. Prefabricated houses not only have to meet design requirements, but also withstand transport loads.

- Shorter construction time: a small modular house can be built in less than two months at the factory. The reason is automation, greater repeat-ability, greater teamwork. Assembly on the construction site is usually finished in a few days.

- Higher quality of the building: very detailed projects can be designed. The increase in design time and costs, are amortized by the fact that a single project, can be replicated many modular homes in series. At the same time, is it possible to obtain modular houses which have every detail elaborated. Also, a definitely higher health and safety level in the factory will increase quality of work.

- Implementation increase: shorter investment time means lower costs for any investor. There is no need to rent social rooms for employees who work on site.

- Contractor’s benefits: modular homes also benefit contractor, stakeholder and their employees. Employees who build a house in a factory do not have to waste time on long travels to construction area. They do not have to work in cold or in rain conditions. Employees have more comfortable working conditions in factory and they can also spend more time with their family. As a result, companies obtain satisfied employees which means a more productive industry.

- Price: modular homes are cheaper than traditional ones. The low cost is because industrial processes, reduce significantly the costs of management related with the building site and all the other additional costs, correlated with on-site construction.

Prefabricated Buildings Limitations

Using the SWOT analysis on prefabrication housing production, is not an easy goal to achieve. Prefabricated system products from factories, meet several well-known problems, when they are applied in the construction industry. As a relatively recent phenomenon, it is not clear whether the construction industry only presents conditions propitious for implementation of prefabricated parts, or if there are also conflicting factors complicating the business of supplying system products. “The issue of industrializing the construction market, through use of prefabricated system products, is closely related to that of modular product architectures, understood as initiatives to break down products or processes into smaller, interchangeable units as a means of achieving efficiency without ignoring customers’ varying needs” (Baldwin & Clark 1997; Sanchez 2004).

Moreover, there are difficulties related mainly with the production process. This happens, because building prefabrication causes problems related to logistics and transport of the final product. Furthermore, prefabricated houses are affected by some disadvantage [9] , including:

- Lifespan: the most common modular homes are timber frame constructed. Analyzing the lifespan of building materials is it possible to understand that brick houses are more durable than the wooden frame ones. However brand-new modular houses have the identical lifespan as brick houses.

- Heat accumulation: timber houses are much lighter than masonry houses, so they do not keep warm and cool down quickly. This is a big drawback. Most central heating installations operate during the day and are switched off at night. In the event of any interruption in the heating operation, the house will get really cold. Prefabricated houses with timber frame technology does not accumulate heat gains from the day. This means that modular homes require very thick insulation to avoid high heat losses.

- Fire resistance: the walls and ceilings of timber made modular houses have only one hour fire resistance. In brick houses, usually two hours. In addition, wood is a combustible material. Concrete and brick are non-flammable.

- Construction limitations: this is not a big drawback, because it is possible to combine several modules together to form one large space. Sometimes when it is necessary to have bigger rooms, it may be more cost-effective to make prefabricated walls only.

- living: people exchange such advantages as delivery time, quality, reasonable price, less risk of theft. Many people, however, are reluctant to live in a prefabricated house. This happens because there are still many doubts about this type of housing.

Annotated bibliography

- Majken Merete Gorm, Kristian KreinerManaging (2006) System products - A case study of prefabricated building parts: Is a paper written in collaboration between CBS (Copenaghen Business School) and the Center for Management Studies of the building Process

- Andrew Martin, Construction Management Depth Analysis: Sequence, Cost, and Schedule Impacts Final Thesis Report of Prefabricated Exterior Panels, written by Andrew Martin and supervised by DR. Chris Magent (Harrisburg University). The focus is on Construction Sequence, Cost, and Schedule Impacts.

- Li, Heng, Guo, Samuel H.L., Skitmore, Ronald Martin, Huang, Ting, Chan, K.Y.N., & Chan, Greg (2011): Rethinking prefabricated Construction Management using the VP-based IKEA model in Hong Kong: Article submitted for consideration in the Construction Management and Economics - Construction Management and Economics

- Zhengdao Li, Geoffrey Qiping Shen, Xiaolong Xue (2014) Critical review of the research on the management of prefabricated construction: Summary on the research development in the management of prefabricated construction (MPC)

- Clyde Zhengdao Li, Jigke Hong, Fan Xue, Geoffrey Qiping Shen, Lizi Luo (2016): SWOT analysis and Internet of Things-enabled platform for prefabrication housing production in Hong Kong

- Humphrey, Albert (December 2005): SWOT Analysis for Management Consulting

References

- ↑ [Mikkelsen et al. 2005: 20; Pine et al. 1995: 105] Managing system products: A case study of prefabricated building parts

- ↑ [1] Scandibyg

- ↑ [Sanchez 2000: 614] Management Studies of the Building Process

- ↑ [(Garud & Kumaraswamy 1995; Sanchez 2000; 2001; 2002A; Sanchez & Mahoney1996)] Construction Management Depth Analysis

- ↑ [Baldwin & Clark 1997; Langlois & Robertson 1992] Portfolio Management in construction

- ↑ [(Brusoni & Prencipe 2001) and (Lau & Yam 2005)]Rethinking Construction Project Management

- ↑ [Chesbrough 2003; Galvin & Morkel 2001; Staudenmayer et al. 2005] Process Management of building parts

- ↑ [Lund 2005: 71-72] Managing system products: A case study of prefabricated building parts

- ↑ [2] CRL - Advantages and Disadvantages of Modular Construction