Failure Mode and Effects Analysis in Various Project Stages

Defects, downtime, injuries and delays can be extremely costly and often directly interfere with a company’s objective of delivering quality and reliability[1],. So how can these events be prevented from occurring?

Extensive testing in the later phases of product development project could for instance be a preventive measure. However discovering the faults at this stage can be very costly and mean even further delays. Instead, it is ideal to take preventive measures, which can be achieved through applying the risk management tool “Failure Modes and Effects Analysis (FMEA)”. FMEA is a systematic step-by-step approach for identifying, analyzing and preventing product and process failures. The tool is often applied in the early stages of a project, but can be used throughout in different variations.

This article aims to inform the reader on how to facilitate FMEA, how it can add value in different phases of a product development process and its limitations.

In this article, a “product” is often referred to as a “system” consisting of sub-systems and components

FMEA

Before discussing the use of FMEA in different project phases, the general concept of the tool and its application will be outlined.

Definition

FMEA is a qualitative tool that investigates how a product or process might fail (failure mode) in delivering its intended function and the consequences of this. The tool applies with the standards of Qualitative Risk Analysis defined by the PMBOK guide, which shortly can be summed up as a prioritization of risks for further investigation by assessing their probability of occurrence and severity [PMBOK guide]. In practice the tools objective and compliance with the standards can be formulated as:

- Identification and understanding of failure modes and their causes, and the effects of failure on the system or end users, for a given product or process.

- Risk assessment associated with the identified failure modes, effects, and causes, and prioritizing of issues for corrective actions.

- Implementation of corrective actions for the most critical failure modes along with evaluation after implementation.

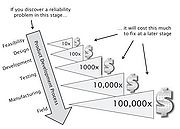

FMEA can be categorized as a proactive risk reduction tool that after initiation becomes a dynamic factor of improvement. This I due to the iterative nature of risks identification where new risks may evolve or existing risks becomes revealed as the project advances through its lifecycle. [PMBOK] The motive for implementing risk identification followed by risk reduction derives from the objective of changing characteristics of the system, without significantly increasing cost. This ability to do so is highest at the projects start and decreases at the project progresses.[pmbok] A general rule of thumb for the phenomenom is the Factor of 10 rule, which states that changing characteristics of a product in a development project multiplies by a factor 10 for each time the project progresses in to a new phase. The factor of 10 rule I illustrated in the figure below.

- ↑ D. H Stamatis, 2003, 2. Edition, "Failure Mode and Effect Analysis – FMEA from theory to execution", ASQ Quality Press. - Step-by-step approach for implementing FMEA including ISO references and Six Sigma practices.