Lean 6 Sigma in project management

Developed by Gustavo Adolfo Ruiz Muñoz

The Lean Six Sigma is a methodology that combines the lean philosophy and the Six Sigma methodology in order to increase the value of resulting products at a lower cost. This combined methodology helps to gain knowledge in how business processes are developed. In project management, this philosophy may help to conduct business processes into more efficient and effective ways. It comprehends all parts of the organization: the overall Portfolio management point of view, the programs developed into a company and finally, the individual projects inside the organization.

The implementation comprehends characteristics of both methodologies, from the 7 waste tool for Lean project management to the Define-Measure-Analyse-Improve-Control(DMAIC) system from Six Sigma. Some other characteristics of Lean Six Sigma implementation, such as the belt certification are described as well. The characteristics of this implementation are discussed and possible drawback are taken into consideration.

Along the description of Lean Six Sigma in project management, some examples will be shown. An illustrative example of DMAIC methodology applied in the Wind Industry for a specific case, or how Lean Six Sigma may help to decide which projects to select are just some of the multiple cases where this methodology may play an important role a firm.

Contents |

Background

In today's world, the strategies in companies are commonly seeking competitive advantages while gaining in profitability and quality. Miscalculation in delivery times or budgets can affect this competitiveness and cause sever risk for the Return Of Investment (ROI). The main advantage doing a correct portfolio management is to optimize the overall programs/projects evaluating each individual project. In traditional portfolio management the progress of each project is tracked against tasks and not value created. This may lead to ineffectiveness that Lean Six Sigma may help to avoid. [1]

The Lean methodology became popular in Japan during the 30 ’s. One of the first applications was focused in textile and cars manufacturing, using the Just In Time(JIT) philosophy for the Toyota firm. This concepts spread around the world and new applications were found such as lean portfolio management.

The Six Sigma concept has a shorter history. It was stablished in 80’s as a new method for quality manufacturing in Motorola. Nowadays, its implementation in management is considerable popular.

Introduction

Lean Six Sigma in project portfolio management is a methodology that combines the philosophy and tools from Lean project management and Six Sigma management. In lean project management the main objective is to minimize costs and maximize the use of the resource available. The project planning includes the allocation of resources according to strategic priorities. Lean methodology adds flexibility and simplicity in the lower stage of the organizational level to align the overall strategic resources of portfolios with individual projects. This alignment is done by decomposing entire programs in small projects. Resources are distributed through an analysis of priority, either through value stream mapping tool or others tools proposed in this article. A set up of small projects enhance the flexibility of the people who are working in those projects. The prioritization is done after an approach to stakeholders and clients to identify features that can increase the ROI of an organization. The estimation of this priorities is done in small cycles since business conditions may change all time. Thus, the priority of different tasks may change as well. [1]

As a complement to the lean philosophy, Six Sigma offers the possibility to improve the quality of processes and products. As a part of the supporting activities of the program management, quality is an important concept in portfolio management. It is a deliverable feature from benefits and it is a requirement for the Program Governance and Risk Management. Apart from the planning point of view, the Quality management plays actually an important role for goals in projects. In Six Sigma project management, procedures are standardized at the operational level of a company and there is a focus in delimited goals in order to reach the highest ROI. It is a methodology that has to be implemented in the entire organization, from the strategic level to the operational level. A strong point that Six Sigma can offers is its capability to align the projects with the strategies followed by the companies. Another interesting feature is that Six Sigma project are commonly for the short term. [2]

Applying both concepts together, lean six sigma is able to: [3].

- Reduce the complexity of business processes: The simplification and standardization may help to improve efficiency and activities inside the organization, e.g. standard analysis in the Center Of Excellence functions.

- Optimize processes: The Lean concepts are able to optimize process using waste reduction tools where delays on delivery can be avoid.

- Develop culture aiming to enhance the performance of operational teams: The Lean Six Sigma philosophy proposed a cultural change in the organization, able to have a deep impact in the performance at operational levels.

Implementation

In order to develop a Lean Six Sigma methodology in project program and portfolio management, several aspects have to be taken into account. For instance, it is recommended to be at least four categories of certified belt employees as in Six Sigma:

Belt Certification

- Champions: They take responsibility of the implementation of Lean Six Sigma across the entire organization.

- Master Black belts: They have coach responsibility and spend all their time in Six Sigma evaluation. They do statistical analysis of data to assure consistency of Six Sigma across function and departments.

- Black Belts: They are focused in specific projects to apply Six Sigma and they dedicate full time for Six Sigma implementation.

- Green Belts: They are the employees who implement Six Sigma in their jobs responsibilities.

The position of certified belt employees might be located inside each of the management levels: In portfolio management, they can influence for example in the decision-making for the strategic approach by applying correctly the Lean Six Sigma methodology and tools. In project management they can assure that certified standards are respected during the development of the projects.

Another concept applied from Six Sigma is the DMAIC framework:

DMAIC

- Define: In this first step, it is defined the opportunities the company has for different projects. It is the most important phase since it targets the limited sources of a company.

Figure 1: DMAIC. [4]

Figure 1: DMAIC. [4]

- Measure: In this phase, the business processes are documented. Measurement techniques are validated and the historical Six Sigma is assessed.

- Analyse: The data collected is analysed and the performance of different projects is evaluated. The root of multiple problems may be found in this phase.

- Improve: The teams in projects are able to eliminate root of problems sufficiently to achieve the overall objectives of a project.

- Control: The companies have been able to establish mechanism of control on possible causes of problems for the long run.

In portfolio management, DMAIC methodology can be used in many ways. It can be used in the decision-making phase of portfolio management at the strategic level to improve the assessment of the orientation of a company.

An example given can be seem for the Wind industry, where subsides are defined as opportunities given for new companies who wants to participate in that market. The subsidies are external benefits given by governments to the wind industry. Those subsidies can be measured and analyse. The data collected can be always improved by assessing financial or political actions. Finally the data is controlled since the wind industry is changing all the time and new green energy source may become as a threat to those subsidies.

All this Six Sigma concept are implemented always taken into account the lean philosophy. Small projects are assigned and there are especial interests in costs and waste. Coming back to the Wind Industry example, residuals or wastes from the data collected can be avoided for the measurement part in DMAIC. Obsolete /wrong data of subsidies per country could be treated as waste and it shall be eliminated using the Lean methodology. Note that this kind of information can affect the decision-making in portfolio management. This is just an example but plenty of other cases could show the implementation of Lean Six Sigma in portfolio, program or project management.

Tools

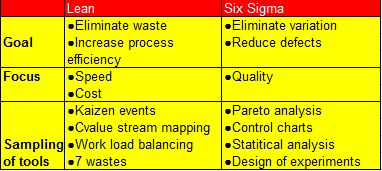

The tools used for the Lean Six Sigma project management are a combination of the tools of both methodologies:

Figure 2. shows the goals, focus and sampling tools for both methodologies. Other tools can be used as well and they shall be chosen according with the portfolio/program/project characteristics.

Lean Tools

- Kaizen Events: This tool is based in the rapid improvement of business processes. It was firstly implemented by Toyota in the manufacturing industry. Nowadays companies use it in portfolio management as well to determine why a project has its certain costs or why a determine number of resource are used in it. These questions may lead to new ones that in the end will help to identify all kind of waste of resources a company may have. [6]

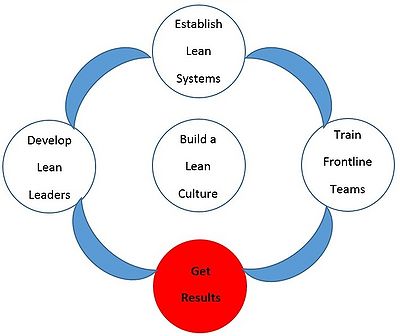

The Kayzen tool help to develop all areas shown in Figure 3. The main objective is to build up a lean culture that would have a direct impact on the business results.

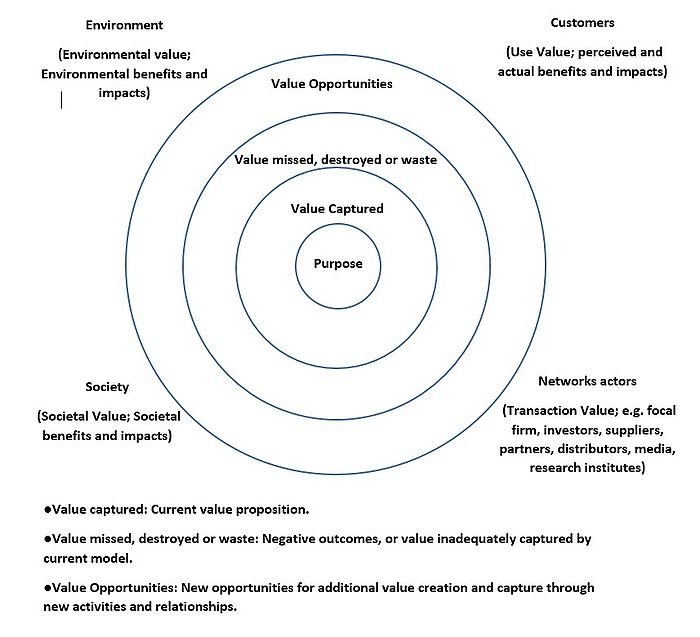

- Value stream mapping: The value stream mapping is a tool to understand every value proposition in a company. It identifies the positive and negative aspects of value proposition. E.g.: the network between stakeholders involved in creation and delivery of new products. It also identifies conflicting values and it identifies opportunities to reoriented projects or entire portfolios to more profitable business processes. [8]

In Figure 4 it can be seen that the purpose of each business task is influenced by multiple factors. The value captured as well as errors and opportunities shall be take into account. External factors: Environment, Customers, Society and Networks have a relevant impact on the value captured.

- Work load balancing: It aims to reduce non-value added activities in a project. Load charts are in literature where timing in different types of operation is controlled. [9] This tool may have deep impact under a program strategy alignment in a business case, since it is able to coordinate times to adjust better to the delivery time. Note that the delivery time and the time to market expected from a product shall be aligned as much as possible in a lean methodology.

- 7 wastes: It is another Lean tool originally used for the manufacturing industry that can be implemented in business growth evaluation. It includes evaluation of putting too much work in progress originating bottle necks. It also analyse delays and extra-capabilities of the organization that were hidden until then. [10]. The 7 wastes can treat as residuals those activities in project management which are considered not to give extra value to the product or seriously deteriorate other important activities. Residuals are erased or reoriented.

Six Sigma Tools

- Pareto analysis: It is a statistical tool for decision-making on the activities who has the bigger effects on a project. It is a key tool in Six Sigma and it consists of a bar chart of activities ordered by their importance. [11]It can be used for example in the Measure step of the DMIAC methodology. It has broad applications as it will be shown in the next section.

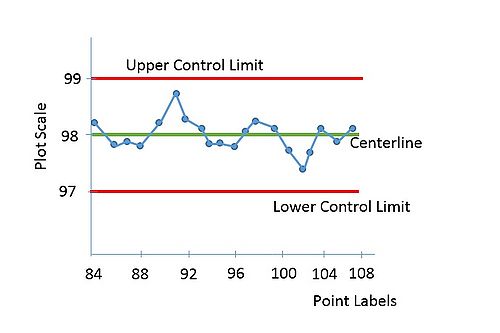

- Control charts: It is a tool to monitor process, stability and control in projects. A control chart follows a time series, where there is a central line of how processes are supposed to be done and deviation of this processes are limited by upper and lower boundaries. [12]. Under a program management point of view, it can be used in a control stage of the Program Governance. Periodic reviews of a program are done in order to determine whether benefits coming from projects are within the boundaries.

- Statistical analysis: The statistical analysis evaluates data gathered in the DMAIC process using statistical tools, from calculating variances to distribution of the data in order to execute some short of control in projects. It help the improve phase of the DMIAC, where several inputs of the model may be changed and new result can show improvements or not. Statistical analysis is a broad topic that can be used every time the DMAIC has measured data. It can be used to assess quality controls in Program Quality Management or to have a deeper understanding in Control Charts.

- Design of experiments (DOE): This tool is used in order to define cause-effect relationship. The commonly terms associated to DOE are the controllable and uncontrollable input factors which are factors that can and cannot changed in a project. It also includes the response or output measures which are the results of business activities. It also includes the hypothesis test, which helps to determine the critical factors for the statistical evaluation. Another concept taken into account during DOE is the interaction between inputs, better known as correlation. Finally blocking and replication are interesting topics for the DOE in order not to modify input information using different measurement tools [14]

Example: The multi-objective case

An example of application of the Lean Six Sigma portfolio management can be found in the literature. In that case it is considered the problems of identifying the projects to implement Lean Six Sigma concepts. As the number of projects increase in a company, the risk of misusing resources of a company increase as well. The successful implementation of Six Sigma in a company involves a management commitment, training, communication and changes in the organization.

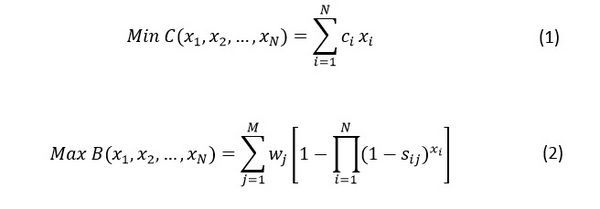

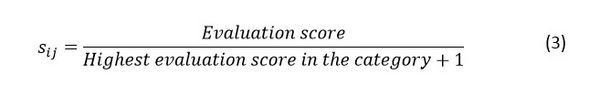

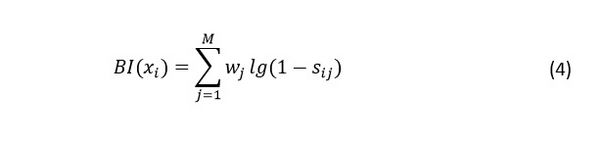

Consider the case where multiple projects are proposed in a company. The correct Lean Six Sigma implementation would deal with maximizing the benefits and minimizing costs:

Where ci are the costs, xi is a binary number which tells if the project is selected, B is the benefits, wj is the weight and sij is the normalized performance score:

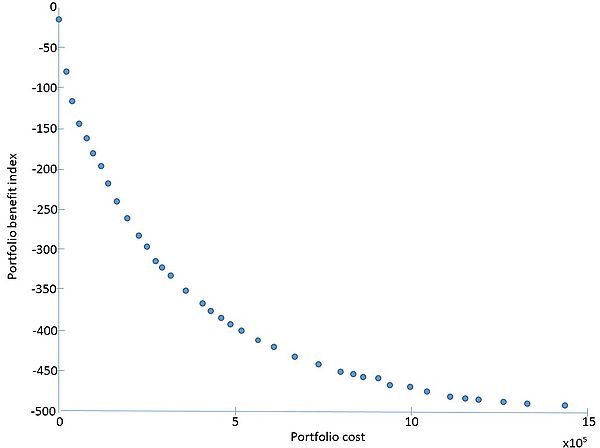

3 kind of constraints are added to the previous mathematical model: Resource constraints, Diversity constraints and Management limit constraint. The resource constraint equation tries to include the limitations a company has to implement Lean Six Sigma in every project selected as there is a limited amount of certified belt employees. Those employees are the only ones capable do those implementations. The Diversity constraint takes into account that Lean Six Sigma may not involve all actors in a project: Decision makers not always want to involve all stake holders in Lean Six Sigma. Finally, the Management constraints equation tries to englobe the limits of projects a management group is able to handle. This analysis was done for a conductor company where 51 proposal project were evaluated. The potential benefit index is given as:

ends showing the following analysis:

Each of the points of Figure 6. shows different optimal for project portfolio. The correct choose of the order in which projects are selected and execute depends on the necessities of a company. In this example, the Pareto frontier tells that for a total selection of projects with a portfolio cost e.g 1 million $ the portfolio benefit index should never be higher than around -470(the lower the better) in order to correctly implement Lean Six Sigma.

The example described shows a direct application of some tools explained in the “Tools” section. A deeper explanations of this case can be found in the literature. [15]

Drawbacks

The implementation of Lean Six Sigma can often lead to loose simplicity of projects. The common pitfalls found are:

- So much attention in belt certification: Coming from the Six Sigma methodology, a proper Lean Six Sigma implementation requires green and black belt certifications. This characteristic may lead employees to complete the belt certification with more enthusiasm than pursuing real value for a business process.

- Unbalanced resources: When there are many belt candidates focused in belt certification there could be a high demand on subject matter experts who are not able to attend to everything.

- Collect too much information or do not evaluate it properly: Six Sigma is a data driven methodology. It is observed in some companies a tendency to collect much more data that required and with poor data quality. Prejudices of people can also provoke not to read data gathered in a proper way.

- Rigid program implementation: As mentioned in previous chapter Lean Six Sigma take advantage of lean implementation in order to enhance speed and flexibility on projects. When the organization focus so much in the methodology tools the company may end up in inflexible procedures where many templates shall be filled out and all this advantages may be lost.

- Not following properly the DMAIC method: Another common mistake in the business world is to go directly for the implementation phase without considering to gather and analyse sufficient data.

- Assume that belt candidates have managerial skills/background: A Lean Six Sigma portfolio management has to include green and black belts employees with sufficient managerial skills and background. It usually happens that the selection of the candidates for the belt certificates have not been done considering that field.

- Assume there is a best way and not better ways: Lean Six Sigma philosophy is a continuous improvement methodology where there is not just a best way to manage projects but there is always better ways for improvement.

Conclusions

The present article shows how two complementary methodologies can be implemented in Project Management. The combination of Lean and Six Sigma philosophy in portfolio management is able to assure business processes at high quality and low cost. This implementation aim to align all activities from a project to the strategic goals of a portfolio. Efficiency and effectiveness is assured by introducing a combination of Lean and Six Sigma tools, as well as Six Sigma methodology called DMAIC.

The implications of introducing Lean Six Sigma has multiple application. Nevertheless its implementation could be difficult. The requirements of belt certificate employees imply to set clear and realistic plans on how to manage organizational changes. It is also recommended to determine which tools described can give value to the business process and be flexible when implementing this combined methodology.

References

- ↑ 1.0 1.1 http://www.netobjectives.com Chapter 4 Lean Portfolio Management. Description: Net Objectives is a company that aims to develop Lean methodology for their clients.

- ↑ M. D., Marly, University Of São Paulo, (2013) Six Sigma Projects: The portfolio Management Perspective Description: Article from the university of São Paulo

- ↑ Labarre, C. ,OTC Conseil Americas Can Lean Six Sigma Streamline Your Project Portfolio? Description: Conseil Americas is an organization focused in risk management and optimization.

- ↑ http://qmssblog.blogspot.dk/2015/03/combining-dmaic-and-lean-events-to.html Combining DMAIC and lean events to maximize process improvements Description: Blog that addresses for the business performance improvement

- ↑ 5.0 5.1 5.2 Lilly,M. DeCoste,D. (2012). Demystifying Lean Six Sigma . Description: Article written in the company website PMtimes, a company related to project management.

- ↑ United States Environmental Protection Agency. Lean Thinking and Methods: Kaizen . Description: Environmental Protection Agency is a government agency that aims to protect human health and the environment.

- ↑ http://www.velaction.com/products-services/lean-consulting/kaizen-event-support/ Kayzen event support Description: Velaction.com is a website for improving the performance of companies and skills of people.

- ↑ 8.0 8.1 Bocken, N.M.P., Short, S., Rana, P., Evans, S., Coporate Governance, Vol. 13 Iss: 5 , pp. 482 – 497 A Value Mapping Tool For Sustainable Business Modelling . Description: This article comes from the University of Cambridge.

- ↑ Quality America Inc. Level Load Balancing . Description: Quality America Inc is a company related to training and certification in Lean Six Sigma

- ↑ Terry, J. http://leankit.com/blog/2015/08/7-wastes-that-impact-business-growth/ 7 Wates That Impact Business Growth. Description: Blog from Leankit, a company dedicated to visual management and forecasting software designed to optimize the effectiveness of workers

- ↑ Haughey, D., http://www.projectsmart.co.uk Pareto Analysis Step by Step Description: ProjectSmart.co.uk is a website which aims to ease the access to project management information.

- ↑ Berardinelli ,C. , http://www.isixsigma.com A Guide To Control Charts Description: iSixSigma is a high-tech B2B dedicated to help busisness and organizations.

- ↑ http://acqnotes.com/acqnote/careerfields/control-chart Production, Quality & Manufacturing Description: Acqnotes.com is a website that provides sources of a department of defence to the aeronautic community.

- ↑ Sundararajan ,K. , http://www.isixsigma.com/tools-templates/design-of-experiments-doe/design-experiments-%E2%90%93-primer/ Design Of Experiments- A Premier

- ↑ 15.0 15.1 Hu, G. , Wang, L. , Fetch, S. , Bidanda, B. (2008) International Journal Of Production Research A Multi-Objective Model For Portfolio Selection To Implement Lean And Six Sigma Concepts Description: The Internation Journal Of Production Research is a journal member of the International Foundation For Production Research, a group related to production systems and processes.