Lean Approach to Scheduling in Construction Projects

Contents |

New title: Scheduling using Location Based Scheduling instead of CPM

Abstract

Scheduling of activities are of utmost importance when starting a new project whatever scale it might be on. It is done to ensure the resources are used efficiently and in most cost effective way[1]. According to PMI (2013) Project Time Management is a crucial part of a project managers scope. Managing a project typically include balancing the competing project constraints, such as quality, schedule, budget, and resources [2].

The first process in Project Time Management, the Plan Schedule Management Process, may involve “choosing strategic options to estimate and schedule the project such as: scheduling methodology, scheduling tools and techniques, estimating approaches, formats, and project management software”[2]. There are various methods and techniques for scheduling of which the most widely used are the Critical Path Method (CPM). CPM is primarily an activity based method that takes the activity as the unit of focus, and is often presented in a Gantt chart[1]. However, criticism of the CPM and Gantt chart has been raised, specifically in the case of construction projects, for not sufficiently supporting management during the construction phase, and not creating a continuous, and thus financial, flow of resources [3][4].

The Location-based Scheduling (LBS) methodology is a Project Time Management tool, designed to plan and manage workflows and may therefore be expected to be a useful alternative to CPM. It implies a shift in focus from primarily the activities to the flow of work through the various locations of the project. LBS is a scheduling method that rests upon the theories of line-of-balance and uses the graphic representation of a flowline chart or "Cyklogram" [3]. In this article the representation will be referred to as a flowline chart.

LBS is placed in the realm of Project Management. The main focus of the article is to describe LBS, a Project Time Management tool, used by project managers in the construction industry.

- Firstly, the article provides an application-oriented description of the scheduling method LBS and its representation in a flowline chart. This part is divided into a theoretical section and an application section. The elements in which LBS and CPM differ, are particularly highlighted.

- Secondly, a discussion of the limitations of LBS is executed.

- Lastly, LBS is compared to CPM, including advantages and disadvantages of both methods. In continuation hereof, it is discussed whether it is favourable to apply the LBS and CPM together.

Big idea: Location Based Scheduling (LBS)

Describe the tool, concept or theory and explain it's purpose. The section should reflect the current state of the art on the topic.

As construction work is generally characterized by continuous or repetitive work, where the same activities are executed at various locations of a building or construction, construction scheduling appears to be more closely aligned to repetitive scheduling methods such as “Line-of-balance”, “Time-location Matrix Model”, “Construction Planning Technique”, “Time Space Scheduling method”, “Flow-Line” and similar methods. Those alternative scheduling techniques, developed over the last 30 years, are also referred to by the generic term of “linear scheduling methods”, and have been proven to be well suited for projects of a repetitive nature. Since, the linear or repetitive scheduling methods strongly suggest locations or places the comprehensive term of “location-based scheduling” (LBS) was introduced by R. Kenley [4].

Location Based Scheduling (LBS) has been known in the Danish construction industry since 1972 unde the name "Cycklogram". It is a scheduling method, that takes into account the location of the activities, i.e. where at the site of construction the production of the activities must be carried out. LBS also provides the opportunity to clarify the flow of production, i.e. how resources and activities are distributed across the different parts of the building [3].

Scheduling principle

LBS as a scheduling method has a lot in common with the traditional Critical Path Method (CPM). The common overall idea of the two methods are:[3].

- The schedule should ensure that the project's goals can be achieved within the time, resource and quality framework that apply to the project.

- The schedule serves as a map of the project showing the planned route from start to finish.

- The schedule serves as a time budget and provides the basis for analyzes and decisions regarding the choice of production methods, materials and equipment and other resources.

- The schedule serves as a communication tool that conveys the structure of the production process - what must be done at each particular time, what resources are to be used, and the order in which the work is to be performed.

- The schedule provides a basis for the follow-up of the realized progress of the project and thus also a basis for identifying possible deviations and their consequences.

The above requirements for the scheduling is independent of the scheduling method, but the way in which these requirements are achieved, is where LBS and CMP differ. Both methods are based on fundamental elements of scheduling such as activities, ressources and activity-links, and LBS also uses the time analysis (network analysis), which underlies the calculation of the critical path in the CPM method. But these typical CPM concepts lose their function in the LBS method, and instead new LBS concepts are introduced: location, location based activities, resource flow and space zone - to name a few. The principal difference between the traditional CPM method and LBS is that the CPM method is based on the activities and their logical connections to each other (an "activity based scheduling method"), while the LBS method is more based on the resources and their "flow" through the project (a "ressource oriented scheduling method"). By flow is meant how the activity of each activity flows through the different parts of a project. For a construction project, the different parts will be equal the different locations on the project. Thus, the geographical location is added as an additional dimension in the schedule. That is, the schedule representation not only tells when, but also where an activity occurs [3]. The schedule representation will be further elaborated in next section.

A study concludes, with emphasis from the site management involved, that the three most important implications of LBS are:[3].

- Improved schedule overview

- Establishment of work-flows

- Improved project control

Identification of locations: Flowline chart

- Flc2.PNG.jpg

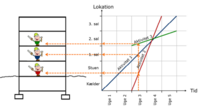

A time schedule made with the LBS method is called a flowline chart. Like in a Gantt chart, which typically is the graphical representation of the CMP method, time is represented on the horizontal axis. In the Gantt chart, the vertical axis represents activities. In a flowline chart, the vertical axis is divided into the locations of the project. The project's activities are instead represented by sloping lines that mark the intersection between time and place for the individual activity. The duration of the activity is reflected by the slope of the line. Figures 1 illustrates how the same schedule can be visualized differently using the Gantt chart and flowline chart, respectively.

Figure 2 illustrates how the flowline chart is read off. It is seen that activity 1 is executed on 1st floor in week 3, and have a duration of one week per floor with a total duration of five weeks.

Application

Provide guidance on how to use the tool/concept/theory and when it's applicable.

With the application of LBS the project manager can

Use LBS to optimize the time schedule

VICO Software

NOT WRITTEN BY MYSELF YET: VICO Control er et software der er specielt udviklet til at lave lokationsbaseret planlægning. Programmet bygger på teorier og metode beskrevet af Russell Kenley og Ölli Sëppanen i: LocationBased Management for Construction(2010). Et nyt projekt i VICO Control begynder med at lave et hierarki. Projektet opdeles i et passende antal niveauer og lokationer (afsnit 7.3.1). Herefter danner VICO Control automatisk et flowlinediagram. Flowline-diagrammet er bygget op med det definerede hierarki på den lodrette akse og tid som anden dimension, på den vandrette akse. Et eksempel på et flowline-diagram blev vidst på Figur 5. Lokationsbaseret Planlægning til Optimering af Tidsplaner DTU 12 juni 2015 Herefter kan aktiviteter kodes ind med navne og varigheder. Efter alle aktiviteter er kodet ind kan de indbyrdes bindinger planlægges. Her har VICO Control flere forskellige visninger af projektet, der gør planlægningen nemmere. Når aktiviteterne er kodet ind, og de indbyrdes bindinger er oprettet, dannes der et overblik over byggeprojektets arbejdsflow. Eventuelle konflikter imellem aktiviteter kan løses, og bemanding kan justeres således at der opnås et optimalt arbejdsflow gennem projektet.

Limitations

Critically reflect on the tool/concept/theory. When possible, substantiate your claims with literature.

Although LBS has a long history and is well-founded theoretically, the method in general has not had much interest in the construction industry. In addition to the results available in the form of theoretical research, there is still limited knowledge about the application of the LBS method in practice. A possible explanation of the limited extent of the method may be that there has been no user-friendly IT-based planning tool for the LBS method. However, IT tools based on location based planning, such as Control™ and Vico Office, has now become unsettled and has been introduced to the 2003 international market[3].

An underlying presumption in this type of work is that LBS mainly is a tool for highly repetitive work (e.g. multi-storey buildings or road constructions) and, consequently, is not suitable for non-repetitive work. The theoretical work provides a solid foundation to the LBS-method, but it does not reveal whether LBS meets the demands of planning, scheduling and control on site and in different kinds of projects [4].

NOT WRITTEN BY MYSELF YET: LBS implies a new, or preferably unfamiliar, scheduling method which requires a new approach to scheduling and it involves new conceptions. For example, LBS requires the definitions of locations and there are different more or less appropriate ways of dividing the project into locations. One aspect is about finding a sufficient level of details required for the planning, scheduling and control of the project. It is possible, but very inconvenient, to change the level of detail once the scheduling has commenced. Another difficulty experienced in one of the cases concerned the definition of different kinds of locations, e.g. how to handle ground works in relation to the locations that are connected to the actual building. The study found no guidelines for the proper approach to defining locations. [4].

NOT WRITTEN BY MYSELF YET: Besides the LBS specific difficulties, some general problems that cannot be directly connected to the specific application of LBS were identified. For instance, it became an apprehension among the site managers that the LBS software requires a significant amount of input information in the initial stage of the planning process. This is a consequence of the design of the LBS software, which uses a bill-of-quantity as the starting point for definition of activities. Thus, the LBS software calculates activity durations from a selection of the bill-of-quantity allocated to a specific activity together with the resources that are allocated and information on productivity for the specific type of work. The site management in this study experienced, which ought to be typical in a Danish context, that they did not have access to a coherent bill-ofquantity for their respective projects. Thus, activity durations were generally valued on basis of the site managements’ individual experiences rather than extracted from bill-of-quantities, documented productivity data or specified numbers of resource units. [4].

LBS vs. CPM

Annotated bibliography

Provide key references (3-q9), where a reader can find additional information on the subject. Summarize and outline the relevance of each reference to the topic (around 100 words per reference). The bibliography is not counted in the suggested 3000 words target length of the article

Harithamahalakshmi, K. et al., 2017. Construction Scheduling Using Critical Path Method And Location Based Management System. SSRG International Journal of Civil Engineering. Available at: www.internationaljournalssrg.org

- Journal that devises an optimal technique of scheduling between CPM and Location Based Management System (LBMS).

Project Management Institute., 2013. A guide to the project management body of knowledge (PMBOK® guide). 5th ed., Available at: http://proquestcombo.safaribooksonline.com.proxy.findit.dtu.dk/book/software-engineering-and-development/project-management/9781935589679/firstchapter

Bertelsen, S., 2012. Håndbog i Trimmet Byggeri - Lean Construction. , pp.1–154. Available at: http://www.leanconstruction.dk/media/8947/Håndbog v 2.1.pdf

Andersson, N. & Jørgensen, B., Practical Implications of Location-based Scheduling. Available at: http://www.leanconstruction.dk/media/16573/Niclas%20Andersson.pdf

- This is the preeminent global standard for project management. It provides project managers with the fundamental practices needed to achieve organizational results and excellence in the practice of project management.

Andersson, N. & Christensen, K., 2007. Location-based Scheduling. Vurdering af LBS-metodens anvendelse i byggeprojekter

Guevara, J., 2015. Lean Construction Methods and CPM Scheduling Work Together - Aegis Project Controls. Available at: http://www.consultaegis.com/news/blog-posts/lean-construction-methods-cpm-scheduling-work-together/

References1

- ↑ 1.0 1.1 Harithamahalakshmi, K. et al., 2017. Construction Scheduling Using Critical Path Method And Location Based Management System. SSRG International Journal of Civil Engineering. Available at: www.internationaljournalssrg.org [Accessed February 8, 2018].

- ↑ 2.0 2.1 Project Management Institute., 2013. A guide to the project management body of knowledge (PMBOK® guide). 5th ed., Available at: http://proquestcombo.safaribooksonline.com.proxy.findit.dtu.dk/book/software-engineering-and-development/project-management/9781935589679/firstchapter [Accessed February 8, 2018]

- ↑ 3.0 3.1 3.2 3.3 3.4 3.5 3.6 Andersson, N. & Christensen, K., 2007. Location-based Scheduling. Vurdering af LBS-metodens anvendelse i byggeprojekter

- ↑ 4.0 4.1 4.2 4.3 4.4 Andersson, N. & Jørgensen, B., Practical Implications of Location-based Scheduling. Available at: http://www.leanconstruction.dk/media/16573/Niclas%20Andersson.pdf [Accessed February 8, 2018]

Cite error: <ref> tag with name "trimmet" defined in <references> is not used in prior text.

Cite error: <ref> tag with name "aegis" defined in <references> is not used in prior text.