Lean project management and its implementation

Contents |

Abstract

Lean management is a popular approach to improving efficiency, reducing waste, and enhancing quality. Lean management is a way of thinking and a systematic approach to eliminate waste, and lean project management is using this approach to create efficiency and delivery better results for costumer’s needs. Lean project management focuses on removing obstacles in the project plan to speed up the project by eliminating unnecessary waste from the project process.

Lean management originated from the Japanese car manufacturing companies such as Toyota in the 1940s and 50s as a response to the country’s socio-technological economic problems of increased competition levels and resource limitations. Lean management has 3 principal sources of waste: Muda, Mura, and Muri. Lean project management seeks to eliminate all 3 sources of waste.

This article will cover the theory behind lean management and lean project management. This will include the background of lean management, and further elaboration on the 3 sources of waste in relation to lean management and lean project management, the 7-types which is specific types of waste, the principles of lean project management, and explain multiple tools and techniques project managers can use in managing lean projects.

This article will also cover how project managers can implement lean management. Implementing lean management can be challenging, and many project managers struggle to achieve the desired results of improving efficiency, reducing waste, and enhancing quality. The project managers must clearly set goals for the implementation and communicate them to the team. In addition, the project manager must have sufficient knowledge of lean and analyze where improvements are necessary for the project process. The lean project manager can introduce lean tools into the project process and provide training to the employees. Lean management is based on continuous learning and improving the project process and because of this monitoring and analyzing progress is a good way to keep the project lean.

Lean project management has many advantages such as high customer satisfaction, reduced costs, and efficient project process. But there are also some limitations for the project manager and the project process such as lack of analysis of which process needs improvement, time-consuming management, and higher risks. All these limitations can cause the opposite effect of the benefits of lean management. Because of this, some areas in the industry make the lean approach more suitable than others.

Theory behind lean

Lean management is a business philosophy and management approach. It aims to increase efficiency and minimize waste by reducing costs and improving quality.

The idea behind lean management is to ensure continuous improvement in the organization by producing a product or service which is needed while minimizing waste in all stages of all processes. Lean management enables the ones using it to be more flexible, adaptable, and responsive to changing customer demands.

Lean management started in the Japanese automotive industry in the 1940s and 1950s when the companies had limited resources and a competitive market. To face these challenges of resources and competitiveness, Toyota developed a production system that eliminated waste and increased process efficiency and known as the Toyota Production System (TPS).

The positive results of the TPS lead to the name lean management in the 1970s and 1980s and had an increased interest in Western countries, and General Motors, Ford, and Boeing all began to adopt lean models into their production process. Today, lean management is widely used to improve efficiency and reduce waste in many different industries such as healthcare, service industries, and software development.

The theory can be applied to many organizations and roles in organizations. Lean project management has and can be expanded to more industries other than production processes including healthcare, construction, and software development.

The 3 sources of waste - Muda, Mura, and Muri

The basis of the Toyota production system and later Lean is to reduce or eliminate 3 types of unnecessary allocation of recourses across the whole project process. These 3 sources are named Muda (無駄, waste) Mura (斑, unevenness), and Muri (無理, overburden).[1]

Muda

The Muda source of waste refers to the elimination of waste in terms of time and resources. Identifying and eliminating any activities that do not add value to the project can reduce waste as much as possible and this is the goal. For project managers managing lean projects, the Muda can for example minimize unnecessary workflows, documentation, or meetings which does not add value to the project.[2]

Mura

Mura can be translated to Unevenness, non-uniforming, and irregularity. It refers to the reduction of variability in the project. Reducing the likelihood of errors and delays can ensure the project is completed on time and within budget. Standardization is a common method to enforce Mura in projects.

Muri

The Muri source of waste refers to the reduction of stains on the project team for lean project management. The goal is to optimize the workload and workflow in the team to ensure efficient work without being overburdened or stressed by people and equipment.

In a lean team, the project manager is responsible for enhancing a reduction of all the 3 M’s in the project process. The management aims to create a streamlined and efficient process that maximizes productivity and minimizes waste and errors.

7 types of waste

The Toyota executive, Taiichi Ohno, identified 7 types of waste (TIMWOODS) found in any process and he is one of the founders of lean management in Japan. Ohno states that “The most important objective for the Toyota system has been to increase the production efficiency by constantly and thoroughly eliminating waste.”.[2]

TIMWOORDS are specific examples of waste that can be eliminated and minimized from a project. The 7 types of waste can be categorized under the Muda, but some of the types can also be categorized under Muri (transportation waste and waiting waste) and Mura (overprocessing waste and defects in waste). [3]

However, not all waste can be eliminated in a team and some waste is necessary to keep up customer satisfaction. An example is in software testing which is an important step in product development that is necessary to have a high-quality product, but the customers are not willing to directly pay for it. Because of this, the waste is categorized into two groups:

- Necessary waste - non-value adding, but necessary to allow for high-quality products. These activities can be testing, planning, reporting, etc.

- Pure waste - non-value adding, but unnecessary to allow for high-quality products. These activities can be waiting and do not bring value to the product and can be eliminated.

The 7-types of waste explained and about avoiding waste for project managers:

- Transportation, Unnecessary transportation of resources which does not add any value to the product. Eg. movements of parts under production, transported healthcare.

- Project management: task switching, interruptions, unnecessary long marketing funnel.

- Inventory, Over-stocks of resources and other inventory which is typically in the case of a company trying to be "on the save side" of avoiding delays, production defects, and more. Eg. Stacks of parts that are waiting to be completed, finished products waiting to be shipped, unneeded documentation in healthcare, etc.

- Project management: purchasing online tools that teams rarely use, and office supplies that exceed needs.

- Motion, Unnecessary movement of employees or machines. Eg. moving people working on products, movement of healthcare staff or patients from one unit to another. This can cause injuries to people and extend the production time.

- Project management: badly structured workspaces, too many meetings, extra effort to find information.

- Waiting, Unnecessary waiting of people and goods. Eg. people waiting to begin the next phase, patients waiting to receive help, etc.

- Project management: waiting for approval from higher management, waiting for unfinished tasks.

- Over-processing, a product with unnecessary steps and features which have not been met by customer demands. A work process with many unnecessary steps.

- Project management: multiple levels of approval for small tasks.

- Over-production of products or work which is not needed

- Project management: filling out unnecessary amounts of documents.

- Defects, in a product and working process which leads to rework or elimination.

- Project management: an incorrect collection of data

The 3 M’s and the 7 types of waste are related concepts, but they are not the same. They can both be used in lean project management to identify and eliminate waste in a project. Understanding the workflow of the project process is therefore crucial to eliminate waste in lean project management.

In addition, it is argued that an eighth type of waste also can be added as a specific type of waste that can be eliminated or minimized .[4]

- Goods and services not meeting the customer’s needs

The eight type of waste has been included to enhance the power of customers’ need in the final products and thereby also in the project process

Lean principles

Lean thinking principles are designed to remove waste from a process and an organization. The key point is that lean project management is trying to do more, by using the least amount of effort, energy, equipment, time, facility space, materials, and capital while meeting the customer’s needs and giving them what they want[4] .

The 5 lean principles are:

- Value is anything the customer is willing to pay for. The customer’s needs and preferences.

- Value stream is a map of the values in the produced items and work process. The steps which do not add value can be eliminated.

- Flow is how work or equipment moves through a process. It was to run smoothly to avoid delays or inefficiency. An un-smoothly flow can be avoided by minimizing waiting wastes

- Pull means that anything should first be produced when it is needed, and then it has to be produced quickly.

- Perfection is an approach to continuous improvement in the value steam mapping, process flow, pull analysis, and other principles. Transparency is a good tool for letting people know where things can be improved.

The principles can be followed by everyone in the work process and can be used as guidelines to optimize the work process and flow. For the lean project manager, the principles can be used to analyze the project’s processes and identify wastes, they can also be used to optimize the use of resources in the project process and make sure the equipment or employees are not overburdened by work. A way of avoiding this can be to prioritize the tasks by importance. The principles can also help to promote continuous improvement in the team the lean project manager is managing. Encouraging the team to help identify areas of waste or important or test new processes can be a way to promote this continuous improvement.

The principles are also similar to project management principles in the PMI standards such as focusing on value, Recognizing, evaluating and responding to system interactions, navigating complexity, demonstrating leadership behavior and enabling change to achieve the envisioned future state.

Lean tools and techniques

Lean management has a range of tools and techniques that are designed to follow the principles of lean management. These tools and techniques can be used by lean project managers and by the people in the team[5]

Lean tools

| Tool | How can it be used in lean project management | Illustration |

|---|---|---|

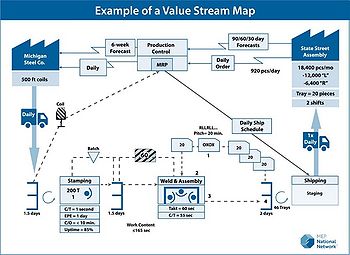

| Value stream mapping | “A lean enterprise method used to document, analyze, and improve the flow of information or materials required to produce a product or service for a customer.” It can help the lean project manager to identify waste and areas for improvement.[5] |

Source: National insititude of standards and technology |

| 5S | A way of organizing the workplace to improve efficiency, safety, and quality. The 5S's stand for Sort, Set in order, Shine, Standardize, and Sustain. |

Souce: 5Stoday.com |

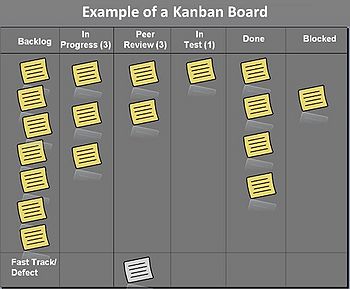

| Kanban board | “A visualization tool that shows work in progress to help identify bottlenecks and overcommitments, thereby allowing the team to optimize the workflow..[5]” |

Source: Wikipedia |

The tools can be used in many different management settings by the project manager and the employees. Even though there are guidelines in how to use the tools, it is up to the team to decide how and when to use them. The use of these tools can further be optimized by testing and engaging with relevant stakeholders.

Lean techniques

| Technique | How a project manager can use the technique | Illustration |

|---|---|---|

| Just-in-time(JIT) | A production and process strategy that allows of producing goods or services when they are needed, in the quantities required, and without excess inventory. This is not a tool the project managers can use, but a strategy which can help to align the decision makings towards the lean principles. |

Source: amsc-usa.com |

| Kaizen | A technique the project managers can adopt to allow for continuous improvement of lean project management. It involves everyone in the team. It emphasizes small changes to improve processes and eliminate waste. |

Source: Adobe |

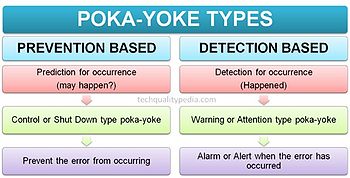

| Poka-yoke | “Poka-Yoke is any mechanism in a Lean manufacturing process that helps to avoid mistakes”[6] Poka-yoke means mistake-proofing and it tries to eliminate errors by preventing and correcting mistakes as they come or by detecting them. |

Source: Tech Quality Pedia |

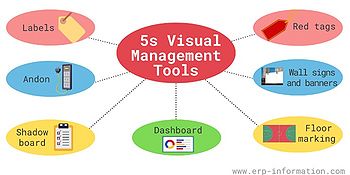

| Visual management | A technique the project managers can use for communicating information to employees and avoid misunderstandings. Multiple tools can be used such as charts and graphs, and other visual tools. It can help employees understand their responsibilities and give them and the project manager the possibility to monitor their performance and progress. |

Source: ERP information |

The techniques can be used in a variety of settings and can be optimized for better following lean project management

Lean project management implementation

Lean management can be implemented within a team, department, and whole organization. [7]. Before implementing lean management it is important to set clear and manageable goals for the team and communicate them. For project managers who might lead a team toward lean management could for example set goals to optimize the workflow to finally make faster deliverables. The implementation method is very similar to the PMI standard model of managing change [8].

Lean management can be adopted in the following way.[7]:

- Develop a clear understanding of lean management principles

- Before implementing lean management, it is important for the project manager to have a clear understanding of the lean principles and theory

- Select a person(s) responsible for leading the implementation

- Select a person responsible for leading the implementation of lean management. In project management, it would most likely become the project manager. The project manager should have sufficient knowledge of lean.

- Identify areas for improvement

- Conduct a thorough analysis of the project or organization to identify areas of improvement and where lean principles can be used. This can involve analyzing processes, workflows, documentation, and software to identify areas of waste.

- Implement lean management tools and techniques

- When the areas for improvement have been identified, the project manager can begin to implement lean management tools and techniques that can help enhance lean project management.

- Provide training and support to the employees

- Project managers or other employees must be trained on lean principles and the tools used in lean management. This will help ensure that everyone in the organization is aligned with the lean management philosophy and can contribute to its implementation. There can potentially be created methodology of usage of tools to ensure further alignment of workflows throughout the teams.

- Monitor and evaluate progress

- To make sure the lean management have the desired affect and are making progress in the team the project manager can begin to monitor progress. This can be done by tracking key performance indicators (KPIs) and speaking with the employees involved in the change.

- Continuously improve

- Lean management must be continuous improved and thereby keep reviewing progress, identifying areas for improvement and implementing or changing tools are techniques used.

When adopting lean management, the people responsible needs to be aware that it is a long-term commitment and there must be a willingness to change within the whole team. Standardization of processes is a popular way to ensure more efficiency in the process but these standardizations have to be implemented and communicated clearly and continuously. The lean tool can be used in many ways, and it is important to settle on one way of using the tool to avoid confusion between employees and project managers. Providing training and visual aids can help align continuous processes between project managers and employees.[9].

Limitations: Pros and Cons of lean management

As written throughout this article there are a lot of customer and organizational benefits by implementing lean project management. However, as in most processes, there is a range of limitations the project managers needs to be aware of before implementing lean in their teams.

Pros of lean project management

- Increased efficiency in the team

- Lean management can help the project manager eliminate waste and improve efficiency within the team’s workflow. This can lead to reduced costs and increased productivity as written in the theory of lean.

- Improved quality

- Lean project management can help the project managers to more quality deliverables and can help to build a good reputation.

- Increased employee engagement

- Lean management encourages employee to follow the lean principles and to help identify improvements in the process. This can lead to a higher job satisfaction.

- More adaptable to change

- Lean project management ensures quick changes to parts of the process which does do create any value to the produced result. This makes it more adaptable to changing consumer or supplier demands.

- Continuous improvement

- Lean management is a continuous improvement process and rely on the team to constantly look for improvements.

Cons of lean project management

- Resistance to change

- Implementing lean management can be challenging, and some employees may be resistant to change

- Time-consuming and costly

- Implementing lean management can be time-consuming and may require many resources and investments.

- Overemphasis on cost-cutting

- In some cases, organizations may become overly focused on cost-cutting at the expense of other important goals. These can be on innovation or employee satisfaction.

- Over-structure

- It can be challenging for project managers to decide what needs to be implemented into a lean management and what is not change. Finding and developing the right solution to making the process more efficient might also take many resources and time.

- More risks

- When following the just-in-time technique where supplies bought, and process started should not occur before they are needed in the chain. If supplies are not delivered in time or sickness within the team happens the whole flow can become very inefficient. This makes more and higher risks in the project plan.

It is important for organizations to carefully consider the pros and cons of lean management before implementing it. While there are many potential benefits, it is also important to be aware of the challenges and limitations of the approach. When developing products or services which need to follow a specific waterfall structure lean project management might not be a good management approach to follow. For example, when developing medicine or medical products which have many regulations to ensure high quality might not be suitable for a lean structure because they do not have a high ratio of changing processes. However, software development might be very suitable for a lean approach as there are fewer regulations and it is less costly to allow process changes.

Notes

The article has inluded knowledge from the website Kanbanize.com, which is a website which are providing knowledge and references to lean management. The references has been included as the website is explaining well lean project management if a reader would like to have futher knowledge in lean management and lean project management.

References

- ↑ M. Helmold, A. K. Yılmaz, T. Flouris, T. Winner, V. Cvetkoska, T. Dathe, 5S Concept: Muda (無駄), Muri (無理) and Mura (斑), (Part of the Management for Professionals book series (MANAGPROF)), 2022.

- ↑ 2.0 2.1 Dr. Jeffrey K., Toyota Way: 14 Management Principles from the World's Greatest Manufacturer, 1st Edition, (McGraw-Hill Education, 2004), Chapter 3

- ↑ Kanbanize.com, 7 Wastes of Lean, https://kanbanize.com/lean-management/value-waste/7-wastes-of-lean

- ↑ 4.0 4.1 D. T. Jones, Lean Thinking: Banish Waste and Create Wealth in Your Corporatio, (Book: Journal of the Operational Research Society, January, 1996).

- ↑ 5.0 5.1 5.2 Project Management Institute, Inc. (PMI), A Guide to the Project Management Body of Knowledge (PMBOK ® Guide) – 7th Edition and The Standard for Project Management, 2021, glossary.

- ↑ Kanbanize.com, What is Poka-Yoke,https://kanbanize.com/lean-management/improvement/what-is-poka-yoke.

- ↑ 7.0 7.1 Kanbanize.com, implementing lean, https://kanbanize.com/lean-management/implementing-lean

- ↑ Project Management Institute, Inc. (PMI), A Guide to the Project Management Body of Knowledge (PMBOK ® Guide) – 7th Edition and The Standard for Project Management, 2021, p. 160-161.

- ↑ C. Murray; E. Cudney, Standardized work in cyclic industries,(in 30th Annual National Conference of the American Society for Engineering Management, 2009), pp. 511-520