Project Life Cycle in Industrial Engineering

Developed by Baptiste Hubert

All projects can be mapped to a generic life cycle structure. This article discusses about a method of project management: Project Life Cycle. A project life cycle is a sequence of steps through from the beginning to the end of the project, they are sequential and, generally in industrial engineering, there are 4 four main phases which are: Initiation, Planning, Execution and Closure (Figure 1[1]).

Phases can be broken down by intermediate milestones, specific results or deliverables. The project life cycle also allows for the gate procedure to be used, this is a tried and tested method for delivering projects on time, within budget and to the expected quality targets.

The life cycle provides the basic framework for managing the project, regardless of the specific work involved, it is independent from the product life cycle produced by or modified by the project.[2]

Firstly, we will give a description, analysis of each phases, and we will give you a small example for each phases. Secondly, we will speak about applications and limitations of Project Life Cycle in Industrial Engineering.

Contents |

Big idea

Most of industrial projects follow a Life Cycle Model [3] which have all the time the same structure, with 4 steps: Initiation, Planning, Execution and Closure. This structure is often used in industrial engineering, because there is a communication with upper management or other entities less familiar with the details of the projects. Taken together, these steps represent the road a project takes from the beginning to its end and are generally referred to as the project “Life Cycle”. The interfaces of the phases form milestones for progress payments and reporting progress to top management, who can then make the decision to abort or provide further funding. Sometime, the production of a prototype begin before the end of the design, this is known as concurrent engineering and is often employed to reduce the overall project programme. [4]

This phase is where the project objectives are defined and the aspects of the project agreed, it is the phase where a problem is identified and potential solutions suggested, the scope of work is now defined in detail.

One of first steps is the stakeholder analysis, understanding which people or organizations will be impacted by or can influence your project, and what is in scope of the project is critical for ensuring your project's success. The easiest way is to ask the project stakeholders to sign the WBS [5] (or PBS). Being asked to sign their agreement against the scope will force a careful analysis of the requirement which can save a lot of time and cost later.

During this phase it is important to talk with project members in order to give an opportunity to engage with anyone who knows the work better than they may do. This stage is also an opportunity to engage the wider project team in working together. Initiation time allows the project team to define the work in a logical way, without being distracted by the timeline which comes later in the planning stage. By ensuring each step of defining your project is done methodically, it will lead to a better result, and increase the chances of project success.

Developing the responsibility assignment matrix [6] (RAM) before the planning stage allows the project team to avoid the distraction of reality at too early a stage. It is too tempting to modify resource requirement because of assumptions about availability instead of simply and methodically agreeing who should have responsibility for what work. It is also important to keep the distinction between responsibility (at this stage) and resource allocation (who will do the work, agreed at the planning stage).

There is often much confusion between programmes and projects. It should be clear at this stage, because there are 3 important parameters in project management: time, cost and quality.

Example initiation phase

A U.S industrial company won a contract to design and set up the first copper mine production in northern Argentina, and there was no existing infrastructure for either the mining industry projects in this part of South America. During the initiation phase of the project, the project manager focused on defining and finding a project leadership team with the knowledge, skills, and experience to manage a large complex project in a remote area of the globe. The project team set up three offices: one was in Chile, where large mining project infrastructure existed, the other two were in Argentina, one was in Buenos Aries to establish relationships and Argentinian expertise, and the second was in Catamarca—the largest town close to the mine site. With offices in place, the project start-up team began developing procedures for getting work done, acquiring the appropriate permits, and developing relationships with Chilean and Argentine partners. [7]

Planning: Organizing and preparing

This phase is where the project is broken down into manageable areas of work, much details as possible, and planned in terms of time, cost and resources. This is a continuous process and will extend throughout the execution phase of the project. The project manager coordinates the preparation of a project budget by providing cost estimates for the labour, equipment, and materials costs. The budget is used to monitor and control cost expenditures during project implementation. Despite the awareness that new projects are delivered on schedule people tend to plan optimistically. It is important to be critical when developing resource and duration estimates and to be realistic. For industrial project, it is better to over deliver than miss your project end date.

In a large project it is common for specialist project planners to be used who may, or may not, understand technical detail. These arguments will continue, but the solution is for project managers and the project team to “own” the plan rather than delegate the process. Every element of the schedule needs to be critically analysed, ensuring that those in the organisation with experience of similar projects or smaller work packages, develop a realistic plan.

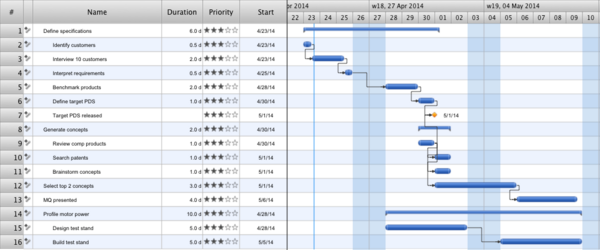

Today there is extensive desktop planning software available, like GanttProject (Figure 2 [8] ), Microsoft Office Projects, OpenProj etc. These have become essential to plan and manage the data of large and complex projects, however, these tools cannot think and they cannot apply experience of the work that a project manager can be have, in the industrial field for example. The temptation to let the software tools do the work is significant, however, project managers need to challenge the plan in all aspects - time, logic and resources.

Every project has different emphasis on time, cost or quality. For a project manager or project team to critically analyse the plan they must understand the project drivers and ensure the plan is weighted accordingly. For example, if the timescale is the key priority then realistic time estimates are essential. If the budget is fixed then minimising cost, sometimes at the expense of schedule, is essential. It is common when project teams challenge these project drivers for them to be told that cost, time and quality are all essential. However, some elements are always more important than others. To apply the same emphasis to all three in an industrial project is to plan to fail. Uncertainty, risk and change is inevitable and the project manager has an ethical duty to understand the project drivers before committing to the project plan.

It is not uncommon for a project manager to be given a delivery date, the budget and the quality perimeters before the project plan has been developed. This is applying reverse logic to the project plan and will set the project team up for failure. However, although sometimes reverse planning is inevitable, it is still the duty of the project manager to be honest with their organisation. This problem can be mitigated by publishing the risk management plan and be producing different planning scenarios for review.

The level of detail that your project needs to be planned at will depend greatly on the size of the project, the amount of information that is available to the project and the amount of visibility and reporting that are required. In a large project it is important to provide a level of detail at which the project can be managed. Presenting the project sponsor or organisation with a complex plan involving many thousands of activities will remove clarity from the plan overall. We recommend a series of planning levels so managers at different levels can review information at the appropriate level of detail.

Example planning phase

During the planning phase, the project team developed an integrated project schedule that coordinated the activities of the design, procurement, and lean production teams. The project controls team also developed a detailed budget that enabled the project team to track project expenditures against the expected expenses. The project design team built on the conceptual design and developed detailed drawings for use by the procurement team. The procurement team used the drawings to begin ordering equipment and materials for the construction team; develop labour projections; refine the schedule; and set up the production site. Although planning is a never-ending process on a project, the planning phase focused on developing sufficient details to allow various parts of the project team to coordinate their work and allow the project management team to make priority decisions. [7]

Execution: Carrying out the work

During this phase the work is implemented, controlled and monitored. The project plan is put into motion and the work of the project is performed. It is important to maintain control and communicate as needed during implementation. Progress is continuously monitored and appropriate adjustments are made. In any project, a project manager spends most of the time in this step. During project implementation, people are carrying out the tasks, and progress information is being reported through regular team meetings. The project manager uses this information to maintain control over the direction of the project by comparing the progress reports with the project plan to measure the performance of the project activities and take corrective action as needed. The first course of action should always be to bring the project back on course (i.e., to return it to the original plan). If that cannot happen, the team should record variations from the original plan and record and publish modifications to the plan. Throughout this step, project sponsors and other key stakeholders should be kept informed of the project’s status according to the agreed-on frequency and format of communication. The plan should be updated and published on a regular basis.

Example execution phase

The implementation phase represents the work done to meet the requirements of the scope of work and fulfil the charter. During the implementation phase, the project team accomplished the work defined in the plan and made adjustments when the project factors changed. Equipment and materials were delivered to the work site, labour was hired and trained, a construction site was built, and all the construction activities, from the arrival of the first dozer to the installation of final production leans switch, were accomplished. [7]

Closure: Closing the project

The purpose of the Project Closure Phase is to formally close the project. During project closure, there are several key activities that need to be performed...

- Verify that the completion criteria are met

- Create a project closure report

- Collect and archive project artefacts

- Perform a project post-mortem

Many projects skip this phase. Once the Execution Phase is complete, they simply move on. It's unfortunate since they really don't know if the project objectives have been met, don't organize the project artefacts to be easily found for future project's reference, and don't identify the key issues and lessons learned by the project that can be applied to future projects. Performing Project Closure will benefit both your company and your career. If you do this well, you will set yourself up to lead high-visibility, business-critical projects. So make sure your projects go through the full project management life cycle.

Example closure phase

The closeout phase included turning over the newly constructed plant to the operations team of the client. A punch list of a few remaining construction items was developed and those items completed. The office in Catamarca was closed, the office in Buenos Aries archived all the project documents, and the Chilean office was already working on the next project. The accounting books were reconciled and closed, final reports written and distributed, and the project manager started on a new project. [7]

Applications

The Project Life Cycle Management can be used to elaborate a business case, to conduct feasibility studies and trade-off analyses etc.

For an industrial project, respecting the life cycle management method is very important. Indeed, for the project manager, the model of the life cycle allows to carry out the project, avoiding any problems related to the progress of the project. This method can be used as soon as a project needs to be completed, such as installing a new production line, or implementing a manufacturing plant in a new environment.

Limitations

It is important to ensure that the project life cycle used for your project is appropriate for the work performed and divided into distinct and manageable phases. It is also important to understand that the life cycle model cannot remove or avoid project-related technical challenges.

This way of manage a project does not adaptable to projects and environments with high levels of uncertainty. It works very well for projects which are well-defined.

Annotated Bibliography

- Project Management Institute (2013). A Guide to the Project Management Body of Knowledge (PMBOK® guide): This book give a global explanation of what is the Project Life Cycle, it is not specific of the industrial field, but it is a really good books about Project management.

- Albert Lester (2007). “Project Management, Planning and Control” : This book explains different methods and model of project management, planning and control, and there is a small part which speak about in details the Life Cycle Models.

- Adrienne Watt (2014). “Project Management”: A large explanations of the Project Management, and an explanation in details of The phase of the Project Life Cycle (Chapter 3).

References

- ↑ Figure 1: Typical cost and staffing levels across a generic project life cycle structure. Project Management Institute. “A Guide to the Project Management Body of Knowledge (PMBOK® guide)” – Fifth Edition, 2013. Page 38

- ↑ Project Management Institute. “A Guide to the Project Management Body of Knowledge (PMBOK® guide)” – Fifth Edition, 2013. Page 38 to 46

- ↑ http://apppm.man.dtu.dk/index.php/Life_Cycle_Model December 2014

- ↑ Albert Lester. “Project Management, Planning and Control” – Fifth Edition. Elsevier Ltd. 2007. Page 37 to 39

- ↑ http://apppm.man.dtu.dk/index.php/Work_Breakdown_Structure_(WBS) September 2015

- ↑ http://apppm.man.dtu.dk/index.php/Responsibility_Assignment_Matrix_(RACI_Matrix) September 2015

- ↑ 7.0 7.1 7.2 7.3 Adrienne Watt. “Project Management”. Creative Commons Attribution 3.0. 2014

- ↑ Figure 2: Example of a Gantt chart for an industrial project. http://www.conceptdraw.com/examples/example-of-gantt-chart ConceptDraw. February 2018