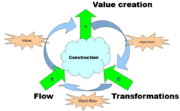

TFV-model

The TFV-Model is an important model in the Lean construction Theory. TFV stands for Transformation (operations), Flow (processes), and Value. The model represents the relationship between these three main components of the management of a construction project, and how they all contribute to its success. The emphasize is placed on creating value for the customer, eradicating non-value adding (waste) activities, and mainly controlling the processes (flow) in a project rather than the operations (transformations/activities) them self. It’s therefore suggested that a process manager should be assigned to any given construction project, and whom would have a vital role for its success.

Contents |

Lean Construction and the TFV theory

Lean Construction is inspired by the general lean production theory, and many of its key concepts are directly taken there from. The biggest difference between the two is, that the construction business works in temporary projects rather than in a continuous production. However Lean Construction tries to benefit from the lean production concepts and methods as much as possible and largely tries to look at construction projects as a form of production. The TFV theory is the main concept in Lean Construction which connects the construction project to production ideas. A discussion of the wording behind “TFV” have occurred about whether or not it’s as appropriate for construction projects as it’s for the production industry. Lean Construction Denmark, the main contributor to the concept in Denmark, have argued that Operations are a more appropriate word than Transformation for the model, since it covers a larger group of activities including non-value adding ones, such as transport, awaiting, and inspections. The reasoning is that such activities should also be included in the wording since they are often paid for equally to the transformative (value-adding) activities. It’s also argued that the prioritized order for the three words should be Value, Flow, and Operations, hence the model should actually be called the VFO-model. However, they have not changed the known name of the model because of the international recognition of it.

Value creation

Value creation, -the starting point of the TFV-model and the main objective of the concept, is reached through the flow and operations. In order to create value for the customer it’s therefore important to understand his/hers needs which decides the baseline for what quality is and the prioritization of the project deliverables. Value Management is by itself a discipline where customer value is seen as a changing factor which the contractor is also able to influence. Operations and processes is always measured on to what degree they are creating value for the customer and whether or not they are doing it at all. It’s thereby not worth it to spend resources on non-value adding activities and processes unless they are absolutely necessary; which in that case they should at least be minimized as much as possible. In the lean theory non-value adding (wasteful) activities are placed in seven categories, which are: - Overproduction - Waiting - Transport - Over-Processing - Inventory - Motion - Defects All of these categories can be related to the construction industry and The Seven Wastes lean concept is therefore inevitable a practical tool in the lean construction process.

Flow

Flow and operations can be seen as two different dimensions of the production. The flow is what happens to the product throughout the production while the operations are what is executed by workers and machines. Optimization of the production should therefore be focused on the flow rather than the single operations; this is because the flow as a whole is what creates value for the customer rather than the single operations. The message is: Do the right things before you do things right. A central concept in regard to optimization of the production flow is the movement from push- to pull logistics. This concept can to some degree be extended to the construction industry. It basically means that a material or product should not be delivered unless it’s requested by the following operation in contrast to it being delivered whenever it’s ready, even though it might not be needed at that time or not needed at such quantities at all. One of this concepts most important benefits have been to eradicate pending inventories and instead getting materials delivered or processed only when needed and when the following process is ready to receive it. Another beneficial concept that have emerged after the pull concept is the ready-for-use packaging idea. Instead of having many separate orders delivered to the same operation, all deliverables needed for that single operation should as far as possible be delivered in one package ready to be implemented. Here it’s important that nothing else, related or unrelated, should be delivered to that operation if it’s not needed at that point of time in the flow. A good example is the Ikea furniture package, -it has all necessary materials to build the finished product and nothing else, neither is anything missing in it. However, if for example a set of doors needs to be delivered to a construction site, handles should be included in the package while locks might be delayed until the end of the project where they usually are installed. In this way the locks won’t be lying around for a long period of time where some of them or parts of them might become missing. Another thing is while e.g. 50 doors might be needed for the whole construction project, only the needed amount at a given time should be delivered, so a space requiring inventory won’t pile up. Such concepts, and others as well, all contribute to the optimization of the flow and a better execution of the project.

Operations (transformation)

From the operations perspective, activities can be divided into value- and non-value adding operations. Whereas value adding activities all together, is the processes that at each operation transforms the subject to a more valuable product until it ‘reaches’ its final form and is delivered to the customer. From a holistic TFV-perspective the value of each transformation should be increased, and the non-value adding operations should be eradicated or at least minimized as much as possible. Examples of non-value adding activities could be transportation, awaiting, and inspections. Time and money used on such activities should be minimized, which can be done through other Lean methods and concepts. As explained earlier, optimization of single operations does not have the highest priority from a Lean perspective, instead it is given to optimization of the flow. However, the two are closely related, and an optimization of operations are often needed in order to optimize the flow. A production example is the optimization of the changeover times in a production line in order to create a better and more flexible flow of different products produced at the same machines and work stations. This will inevitably also require an optimization of the single operation which might not be a technical easy task.

Implications of the TFV-model

An important implication of the TFV-model is that while value should be created through the flow and operations, optimization can also be achieved in between them, -that is the work-flow. A better work flow, among other things, means that the different operations are performed in pace with each other. It’s not sufficient that a certain operation works much faster than the following one, since the following operation will become a bottleneck for the flow. A work-flow where the sequential operations are in pace with each other is therefore needed. One way to optimize the planning of the project flow is through Location Based Scheduling. (Please see the link for more information on this method) In short it is to move from a classical Gant schedule, which simply arrange activities in their sequential order with some flexibility which allows overlapping activities, to a schedule based on the work locations where activities are represented as one or more lines across the calendar. This allows much more flexibility in the planning and makes holes in the schedule obvious for locations that are not finished. Please see the example on the right hand.