The A3 report

Developed by Lise Sjørup Elle

The A3 report is a widely used LEAN-tool which derives from Toyota's production system. It is used in various industries and has a range of different applications. Most commonly the A3 report is used as a tool for problem-solving, communication, knowledge-sharing etc. in organisations. This article will describe the origin of the A3 report as well as the three overall types; the problem-solving A3 report, the proposal A3 report and the status A3 report. A stepwise description of each type of A3 report is provided as well as references for filled in A3 reports. Furthermore this article breaks down the content elements in the different A3 reports and provides the basis for customization to a specific need. Finally it is described how the different A3 reports can be used as tools for solving challenges in program management.

Introduction

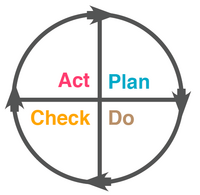

The name of the "A3 report" refers to the standard size A3-paper on which it fits. The idea behind the tool was developed by Toyota and has been used since the 1960’s. It became a part of the Toyota Production System as a standard for problem solving, proposals, plans and status reviews. The A3 report is designed around a Plan-Do-Check-Act (PDCA) cycle developed by Walter Shewhart. The PDCA system is a way of continuously improving and managing an organization in a systematic way. The A3 report documents the findings from the PDCA cycle but is very flexible to the situation for which it is used to describe and/or analyse.[1] The A3 describes in principal the chronological story of the PDCA in one or more A3’s by step wise going through the different stages of the PDCA. For this reason the A3 report has been referred to as “Standardised storytelling”.[2] Even though the tool origins and is widely used in manufacturing, it has been applied successfully in a range of industries such as healthcare, for educational purposes, aircraft maintenance[1] as well as construction[3].

A3 report templates

Today the A3 report is a common Lean tool used as a part of Lean management. The A3 report has developed into several variations as specific tools for problem solving, innovating and planning as well as a general thinking within all levels of an organization. This has lead to the A3 report not only being a problem-solving tool but a tool that facilitates the A3-thinking in different ways. Common for the different types of A3 reports is that they follow the PDCA cycle[4]. This section provides an overview of the different types of A3’s, recommended content and templates. In general it is recommended to use a high level of facts and figures in a simple way which is easily read and understand[4]. The following sections describe stepwise which elements the different A3 reports consist of and what they encounter.

The problem-solving A3 report

This A3 report is the most common type of A3 report. An example of the problem-solving A3 report used for increasing market-share for a specific product can be found in The A3 Lean Management and Leadership Thought Process. Another example of supporting launch objectives with accurate, timely documentation can be found in Toyota's Secret: The A3 Report. A more operational example is reducing scrap in the machine shop which can be found in Understanding A3 Thinking, A Critical Component of Toyota's PDCA Management System.

Plan

- A description of the problem, background and context that provides an understanding of the root causes of the problem[2]. This phase usually takes up the left half of the A3 report.

- 1. Background

- This section describes the extend and importance of the problem.

- 2. Current state

- This section describes the current situation within the company in relation to the problem.

- 3. Future state/goal

- The goals for the future state is described in this section.

- 4. Root-cause analysis

- The root-cause of the problem describes what needs to be solved in order to achieve the goal. There are several ways to analyse the root cause:

- *The Toyota way: asking why five times or until the root-cause is found

- *The Ishikawa “fishbone diagram”

- *The reality tree

Do

- 5. Countermeasures

- In this section different countermeasures for hypotheses are described and tested by changing and adjusting different parameters. Testing and exploration of the many different countermeasures creates a more thought through basis for choosing the best solution. The countermeasures should solve the gap between current state and the desired future state.

Check

- 6. Effect

- Studies the effect of the “Do” phase. It discusses the success and failure of the implemented countermeasures. The “Check” section of the A3-report is in some templates integrated in the “Do” section[2] and in other templates it is a separate section[1].

Act

- 7. Action plan

- In this phase an action plan is created to solve the long-term problem. It is analysed if standardization should be implemented based on a positive outcome from the countermeasures. The action plan can be made in different ways e.g. as a list of actions[1] or an actual project plan with timelines[2]. If the countermeasures were not beneficial the PDCA cycle can be repeated as an iterative process.

The proposal A3 report

This type of A3-report has the purpose of creating a proposal to the organization. This means that it isn’t necessarily a problem that the A3 owner wants to address but it might be an opportunity. Furthermore the emphasis of this type of A3 is placed on the planning-phase. An example of this type of A3 is a Reduction on change-request processes [5]. Two additional examples can be found in Understanding A3 Thinking, A Critical Component of Toyota's PDCA Management System.

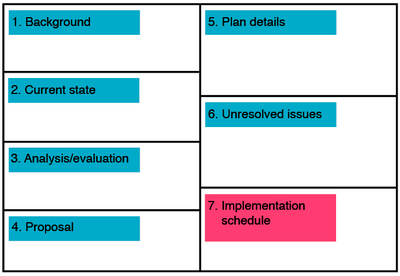

Plan

- 1. Background

- This section describes the extent and importance of the problem or opportunity. It should be described how the opportunity relates to the goals and value of the company[4].

- 2. Current state

- This section describes the current situation within the company in relation to the problem or opportunity.

- 3. Analysis/evaluation of alternatives

- This section is highly dependent on the type of proposal and if it’s a problem or an opportunity. If the A3 report describes a proposal of a future state this step might be irrelevant.

- 4. Proposal

- This section should describe the a concise proposal statement and an analysis of what is achieved including savings in terms of cost and time.

- 5. Plan details

- The details of the implementation are described in this section. This can include a list of actions in order to achieve the proposal.

- 6. Unresolved issues (optional)

- This section functions as a “parking lot” for issues that should be addressed in relation to the proposal but for various reasons are out of scope of the project.

Do, check, act

- 7. Implementation schedule

- Similar to the problem-solving A3 the proposal A3 contains a detailed timeline describing execution.

The status A3 report

This type of A3 report reviews the project and can be used at various points in time during a project as well as provide an end status[4]. An example of a status A3 report is a project status review of lead time and inventory reduction which can be found in Understanding A3 Thinking, A Critical Component of Toyota's PDCA Management System.

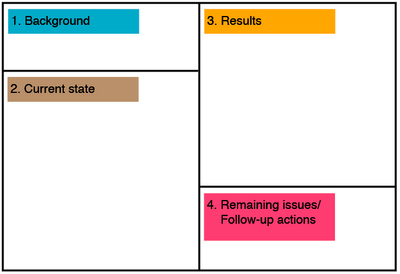

Plan

- 1. Background

- This section describes the extent and importance of the problem or opportunity. For the status A3 this section has a high dependency on who the receiver of the review is and the knowledge of this person.

Do

- 2. Current state

- The current state describes the new state after actions have been taken or a summary of the changes. The current state could be described by using a Gantt Chart[4].

Check

- 3. Results

- This section describes the obtained results from the actions taken at the point in time. Often this section related to metrics such as quality, cost and time.

Act

- 4. Remaining issues/follow-up actions

- Describes the steps necessary to accomplish the goal of the project.

Discussion and implementation advice

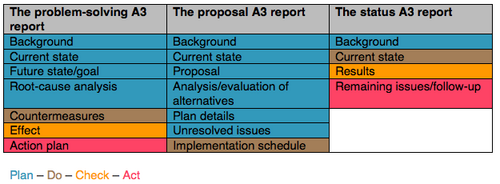

The A3 report is not a fixed setup meaning that it should be created to fit the specific situation and environment which it is used for. This section will provide an overview of the different elements of content within each of the three standard A3 report templates described above as well as discussing the differences.

Focus and application

Figure 4 shows each content element within the specific type of A3 report. The color-codes describe which of the phases in the PDCA cycle the element belongs to.

The problem-solving A3 report is the original A3 report and origins from a manufacturing environment. For this reason this type of A3 report has a strong focus on problems related to delivery, productivity, cost and safety[4]. This is shown by the root-cause analysis which can be executed in several ways and where the aim is to get to the bottom of the problem. Furthermore there is a strong focus on solving the problem short term with countermeasures as well as long term with follow-up actions. From figure 5 it is seen that the planning phase takes up a great part of the content within the problem-solving A3 report which includes the root-cause analysis. In general the problem-solving A3 is objective, data-driven, focused on finding root-causes and solving them on a short- and long-term basis.

On the other hand there is the proposal A3 report which addresses opportunities and focuses on improving the current state. This type of A3 often deals with larger investments or use of resources. Therefore a great emphasis is placed on the planning phase which takes up most of the A3 report. The planning phase describes in detail what can be improved, how the change relates to the strategy of the company, how the improvement should be carried out and what the expected benefits are. It has to convince the receiver that the proposal is a good idea.

The status A3 report is also based on the PDCA cycle but is another type of tool than the other A3 reports. This type of A3 report effectively communicates the status of a project, actions etc. This is reflected in the A3 content, which only contains four basic elements. It can be used in continuation of the two other A3 reports after actions have been taken. This A3 therefore serves another need than the two A3 reports described previously.

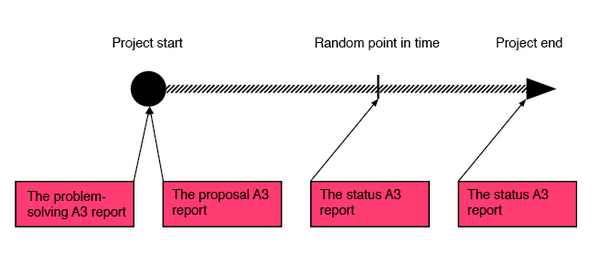

The three types of A3's shouldn't replace each other since they are addressing different aspects and situations within an organization. Figure 6 shows how the three different A3 report templates can be used in various steps of a project. The Problem-solving A3 report can be used to start up a project due to the long-term problem-solving part. This also applies to the proposal A3 report since the proposal is often an improvement that requires a project. The status A3 report can be used as often as desired during a project to provide status updates to stakeholders. The three A3 reports can, however, be combined and customized so they fit the needs of the user and receiver.Users and requirements

The A3 problem-solving report can be used even with a minimal knowledge of the processes within an organization. It is valuable to have inputs from several people when it comes to this type of A3 report because different angles on how the problem has occurred will increase the chance of getting it right and not overlooking important aspects. The proposal A3 report requires employees to have a deeper understanding of the processes within the organization in order to come up with ideas for improvement, relate them to the strategy of the company and evaluate the benefits[4]. The status A3 report can be used by anybody who has knowledge of the project at hand and wants to provide an update of it to stakeholders, internal as well as external.

Application examples: project/program management

As stated in the Discussion and implementation advice section the A3 reports can be used in a range of variations and combinations for different purposes. This article will provide an application example by describing how the A3 reports are beneficial in addressing challenges within program management.

Ten overall themes of challenges for managing engineering programs are described in the guide to LEAN ENABLERS for MANAGING ENGINEERING PROGRAMS. The guide describes how Lean enablers based on Lean principles can be used to solve the themes of challenges[6]. as an extension this article suggests that the different A3 reports can be used as specific tools to support the process of solving a number of the themes. The A3 reports can, of course, not stand alone and clearly have their limitations but they support the themes in the following ways:

Theme: “Fire fighting”

This theme means that the program is reactive instead of proactive. The resources are focused on solving problems and not preventing them[6]. In this article it is proposed that the proposal A3 report is used for including employees at all levels of the organisation in a proactive approach. In this way the need for resources is spread to all levels of the organisation. The proposal A3 report is build around the PDCA cycle and can thereby be used by management to enact the PDCA cycle as a philosophy[4].

Theme: “locally optimized processes that are not integrated across the entire enterprise”

This theme includes processes which are only optimized locally as well as a lack of standardisation and mechanisms for value stream improvement[6]. In this article it is proposed that proposal A3 reports are used for standardisation and knowledge sharing across the organization. When optimizations are made locally they are documented and planned on the proposal A3’s, which can then be shared with other departments. Furthermore the proposal A3 will introduce standardized procedures for how to propose and describe optimizations.

Theme: “Unclear roles, responsibilities and accountability”

This theme includes a lacking definition of who is responsible for carrying out projects and actions within the program[6]. To address the theme this article proposes the use of all three types of A3 reports since all of the A3 reports contains clearly defined roles and responsibilities in “Do” and “Act” phases[4].

Theme: “mismanagement of program culture, team competency and knowledge”

This theme addresses, among other, knowledge sharing from experienced employees to new employees[6]. This article proposes that the problem-solving A3 report is used to solve problems. By using the problem solving A3 report problem solving is standardised and documented as well as easy to find if a similar problem should arise.

Theme: "Insufficient program planning"

This theme includes insufficient adaption to changes in the program environment such as cost and plans[6]. In this article it is proposed that the A3 status report can be used as a systematic and aligned way of reporting changes in projects within the program. The status A3 report can provide systematic information across the organisation as input for program managers to systematically update program cost and plans.

Perspective

The A3 report is a flexible Lean tool which comes in a range of variations serving different needs in organisations. In general there are three overall types; the problem-solving A3 report, the proposal A3 report and the status A3 report. There are, however, examples of other types of A3 reports deriving from the original ones which are discussed and shared at online forums. One example is a strategic A3 report which is similar to the proposal A3 report but focuses on bigger strategic proposals[7]. This illustrates how the A3 report can be customized to a specific need and rather is a way of thinking than a rigid tool.

This article suggests how program management can benefit from incorporating the different A3 reports in solving typical challenges within the topic. The A3 reports are build on Lean principles such as the PDCA cycle and are therefore extensions to theory describing how Lean is implemented and used in an organisation.

References

- ↑ 1.0 1.1 1.2 1.3 Schwagerman III, W. C., & Ulmer, J. M. (2013). The A3 Lean Management and Leadership Thought Process. Journal of Technology, Management & Applied Engineering, 29(4).

- ↑ 2.0 2.1 2.2 2.3 Shook, J. (2009). Toyota's secret: the A3 report. MIT Sloan management review, 50(4), 30-33.

- ↑ Ko, C. H., & Tsai, P. C. (2013). Applying Lean Production A3 to Enhance Construction Work Flow. Life Science Journal, 10(2).

- ↑ 4.0 4.1 4.2 4.3 4.4 4.5 4.6 4.7 4.8 Sobek II, D. K., & Smalley, A. (2011). Understanding A3 thinking: a critical component of Toyota's PDCA management system. CRC Press.

- ↑ https://www.thalesgroup.com/sites/default/files/asset/document/INCOSE-2012-Paper_THALES-Rework_TSA1012021-02_EN.pdf

- ↑ 6.0 6.1 6.2 6.3 6.4 6.5 Oehmen, J., Oppenheim, B. W., Secor, D., Norman, E., Rebentisch, E., Sopko, J. A., ... & Driessnack, J. (2012). The Guide to Lean Enablers for Managing Engineering Programs.

- ↑ http://thetoyotagal.blogspot.dk/2010/11/how-many-different-types-of-a3s-are.html

Further reading

Relevant articles on the APPPM Wiki for further information and inspiration: