The Just In Time concept in construction

Developed by Lasse Hybel

The construction industry is mainly project based, and renowned to be inefficient with low productivity, and to be an industry that often encounters difficulties with keeping time schedules due to delays during the construction period. Concerning the construction management, the introduction of the Just-in-time (JIT) concept can be advantageous, when managing the logistics of the building materials and workforce on the building sites.

The JIT philosophy was originally developed for the manufacturing industry, where it is a method of forwarding materiel or work from one process to the next, at the moment where it is required at the succeeding process. Thus, reducing work-in-process inventory, production cycle times since less time is spend on queuing before being processed and the reduction of flow variation, resulting in continuous ongoing improvements.

There is a significant difference in how JIT is implemented in the construction industry compared to the manufacturing industry. This is because construction is a different type of production, which can more closely be resembled with product development, than with manufacturing. If not taking into account the industry of ‘assembly line housing’. In general, there is a far greater complexity and uncertainty in construction.

JIT is a concept from the lean philosophy, and the goal of the JIT concept is to reduce, or ultimately eradicate, variations and waste. In the construction industry this waste is waiting, storing inventory and moving materials.

Contents |

Lean Construction

History

Lean manufacturing was originally pioneered and developed at the Toyota Motors Corporation manufacturing plants in Japan, based on the ideas of the employed Engineer, Ohno Taiichi [1]. The lean concept JIT, should contribute to the increase of production volume and the productivity in a mixed small-series-production (lots of many product varieties). Lean and JIT was therefore a response to the production demands arising in Japan after the second world war, where the production machinery should convert to the production of cars and trucks among others, instead of weapons [2].

Lean Philosophy

Lean construction is a management philosophy spun of from the principles of lean manufacturing. Lean is a philosophy that focuses on value instead of cost, and seeks to optimize productivity by removing all non-value adding processes. Ohno specified the following concepts, which became the five governing principles of lean:

- Precisely specify value from the ultimate costumer’s perspective

- Identify the value delivery process (Value stream) – Eliminate non-value adding steps

- Make the value adding steps flow without interruption

- Establish a pull from the costumer. Do not produce until it is needed.

- Pursue perfection

These principles all concerns the problem of waste, or Muda in Japanese. Activities or processes that takes up resources without creating value, which should be eliminated in order to deliver things right at the right time - For the good of the producer and the costumer. The different types of waste that can occur in a production, were defined by Wormack and Jones [3]:

- Defects in products

- Overproduction of items no one wants;

- Inventory waiting to be processed;

- Unneeded processing;

- Unnecessary transport of goods;

- People waiting for input to work on;

- Design of goods and services that do not satisfy customer needs.

In order to achieve an optimal production without waste, the following concepts and ideas have been developed as management tools.

Just in time (JIT)

JIT is a method of forwarding material or specific manpower or traits at the exact moment where it is needed, reducing on site inventories and inefficient man-hours (Waiting, and double handling). The following concepts are essential to managing JIT.

One Piece flow: One product on the assembly line at the time. E.g. at a car factory several different models in several different colors can be constructed on the same assembly line.

Pull: There is a pull throughout the assembly line and the suppliers.

Tact: Strict timeline. It is required to know at exactly what time a given product is at a certain time.

Kaizen

The lean concept requires a strict set of standards. However, these standards should be continuously improved, to continuously increase the productivity. This philosophy is named Kaizen.

Andon

Andon is a method of keeping the workforce informed of the progress towards their production/involvement by use of information displays such as light boards or post-it boards, making it possible for everyone to be up to date with the status off all operations at any given time.

Stop the Line

It is better to stop the assembly line, or hold the construction flow, and fix any errors as they occur, instead of letting the dysfunctional product proceed throughout the production, to be repaired after the product is finished.

Poka Yoke

A concept from the idea of ‘right the first time’, which is essential. It is a concept that states that at process should not be able to go wrong. This can be implemented by ensuring that the product only can be assembled in one way. This philosophy is termed Poka Yoke.

Last Planner system (LP)

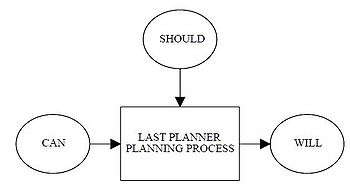

The Last Planner System is a commitment based planning system which integrates ‘should-can-will’ planning with analysis of the constraints of the upcoming process. ‘Should’ is the pull planning, ‘can’ is make ready and ‘will’ is the look ahead planning. All participants in the project agrees on a process plan, but not schedule. There is never detailed plans for more than one week at the time, to ensure a high plan reliability and activity predictability. When keeping the commitments of what is agreed ‘will’ be done, to what ‘should’ be done, but limited by what ‘can’ be done, yields a stable work environment. The manager should only assign work activities which he knows can be done. If the activities do not obey these limitations, uncertainty will be inherited by direct workers, resulting in a high percentage of non-productive time and a demotivated work force [4]. The work is continuously evaluated, by monitoring how much was actually done, compared to previously commitment to what ‘will’ be done. This notion is termed PPC, or the Percentage of Planned Activities Completed [5].

Cho and Ballard [6] has shown that there is a significant correlation between the implementation of LP and project performance – The sum of cost and schedule reduction percentages.

Kanban

Kanban, which translates to ‘signboard’ or ‘billboard’, is a scheduling system that controls the production inventory. The system insures, that whatever is produced is throughput, i.e. needed for the production of an order.

Towards JIT in Construction

The Purpose of JIT is to reduce cost by eliminating waste related to material storage, but also labor time and transportation. There is a significant amount of value to gain by doing so, Hammerlund [7] has previously shown that approximately a third of the time a worker spends on the building site, is regarding the procurement of materials needed by him, which adds up to ten percent of the total building cost. The optimum concept that JIT is, will only increase supply costs marginally compared to the magnitude of waste eliminated, thus increasing productivity [8]. The waste in the construction industry is somewhat identified and the introduction of JIT can be justified. However, the application of JIT in the construction industry is substantially different to that of the manufacturing industry, due to their different types of production, and because of the greater complexity and uncertainty in construction. Construction is best conceived as a product development process. The construction industry consists of building projects, that are scheduled driven. A smooth work flow and a high work performance is achieved if the schedule is kept. However, that is often not the case with specially large scale projects. Design modifications, slips in the deliveries, unforeseen complications and etc. are most likely to occur. The work flow can be shielded from some of these flow variations by keeping a inventory. At the Toyota plant, Ohno successfully minimized inventories between any process, thus also reducing the safety stock that allows the continuity of a process downstream, should any deliver variation occur. What buffers are there in a construction project, that conceal variation and ensures a safety stocks, but also act as waste?

Construction Buffers

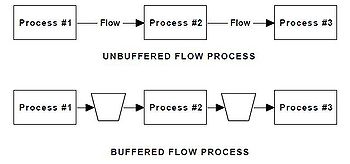

Ballard and Howell [9] defines two inventory types that might shield, or buffer, downstream construction processes from flow variations, together with suggestion rules for how to utilize them optimally.

- Schedule buffers: Piles of stuff: Materials, tools, equipment, manpower, etc. May originate in decisions to insert time intervals between scheduled activities. Act as added time to the project duration.

- Plan buffers: Inventories of workable assignments, made by planning processes that make work ready for downstream production. Buffer by enabling a reliable and predictable flow output from a given process.

In general, increasing the schedule buffers between supplier and construction, leads to an increased shielding from late deliveries, but does not address the cause to the problem of flow variation. This is obviously an expensive shielding application, both regarding time and money.

Thus, it is suggested to implement schedule buffers after processes with variable output. In general, fabrication and delivery can be considered to be very reliable and predictable, why the buffers with advantage should be placed between engineering and fabrication, instead of between fabrication and installation. This ensures that engineering completes its work correctly, increasing the chance that the design is final. However, this is obviously difficult to incorporate in fast-track projects. An additional rule states that schedule buffers should be sized to the degree of uncertainty and variation to be managed.

Plan buffers are required, and not to be replaced by schedule buffers. E.g. having a stock of an item, does not provide a working crew with workable assignments to install the items, and operate any transportation vehicle. At the site, assembling of components, determining optimum sequencing etc. is most optimal done before making assignments and committing to the work that will be done in the plan period (which is often one week, i.e. The Last Planner system). The plan buffers here determine what ‘can’ be done compared to what ‘should’ be done. Finally, the commitment to what ‘will’ be done, is governed by what ‘can’ be done. The future planning can now be improved by monitoring the PPC.

Thus, if considering a construction process as a complex of work processes, a manager in charge of a downstream process can optimize piles of stuff he might have scheduled with, as shielding from unreliable inflow, if he has knowledge regarding the PPC of the previous process.

Strategy for JIT implementation in construction

JIT strives to eliminate physical buffers which is material inventories and time, and to obtain a one-piece flow within processes. This can be achieved at a production line, due to the high stability of the flow obtained by the production scheduling. However, such stability can not be obtained with construction scheduling, why it would be hazardous to simply remove all physical buffers, if the source of variation and uncertainty can not be eliminated. Ballard and Howell proposed the following strategies for the development and implementation of construction JIT, through the management of buffers.

Better location and sizing of schedule buffers: Better assessment tools should be developed, to determine project uncertainties and the quantitative relationship between a buffer and the uncertainty they are intended to shield against. I.e. by improving the management of uncertainties and thus eliminating the causes of flow variation, physical buffers can be minimized.

Place plan buffers and make ready processes in front of each production processes: The hypothesis is that production can indeed be shielded from upstream uncertainty through planning. Thus the use of the last planner system should be increased. The benefits will thus be: The last planner method of detailed production planning shields production from uncertainties upstream. This will ideally result in the revelation of sources of variation and uncertainty which will enhance the productivity while releasing resources for further improvement of the performance of the process shielded, and provide a highly predictable work flow in the near-term to processes downstream.

Progressively replace schedule buffers with plan buffers: The ultimate goal in the construction industry here is to obtain a predictability and reliability, so it can be totally independent of piles of stuff, and time between production processes. The Hypothesis here is that work flow variations can indeed be reduced. If so, the following benefits will be implied. The buffer sizes can be reduced if flow variations are reduced. A reduction of these buffers between the event driven process chain (EPC) functions will yield a reduction of the total project duration. Furthermore, if work flow is more predictable, material, labor and other resources can be better matched at the right time to the work flow, and therefore increase the productivity. Thus, the implementation of plan buffers will propagate certainty throughout a given project.

Furthermore, the contractor can implement the following initiatives in the effort to overcome the problem of constantly dealing with unique projects instead of standard design projects, Pheng & Shang (2011) [10]. Training workshops and seminars for the development of better communication skills. - If engineers know more about the clients needs and expectations, rework can be avoided. Improving the build-ability of designs, by incorporating buildable principles (Poka Yoke). Implementing new integrated approaches for procurement such as D&B, instead of the traditional procurement processes, together with the establishment of supporting in-house design teams. The procurement process is indeed vital for the success of the JIT process. Procurement can be stabilized by ensuring long term supplier relationships. Thus, the following strategies are suggested: Develop a localized supply chain with few sources of supply. In the long run, the stability can be optimized by establishing partnerships with the best suppliers among them. Furthermore, long term relationships with subcontractors should be established, with a strict minimum quality level of acceptance. In general, these are all initiatives that strives to stabilize the variations in the work-flow.

Benefits of JIT in construction

In addition to the previous discussed benefits of utilizing JIT, Pheng and Shang reports the following possible benefits [10]:

- Increasing the competitive advantage of firms in terms of consistently and continuously meeting costumer’s requirements.

- Improving quality of construction materials and components

- Increase in productivity.

- Reduced costs due to minimized inventories

- Improved relationship with supplier

- Work completed ahead of time schedule

- Improving the tidiness of the construction site

- Elimination of site congestion and reduced inconvenience experienced by neighbors

However, these possible benefits can not be achieved without initial investments. For example, more advanced equipment and more skilled employees are required, if the setup time is to be reduced.

Barriers to the implementation of JIT

Several actors have failed in their efforts to successfully implement the JIT concept, due to a variety of problems. The implementation barriers encountered can be broadly classified into two categories [10]:. The first is industry related problems which includes the limitations of building regulations, lack of certainty, inflexibility of JIT scheduling. The other category is human related problems, which concerns the influence of stakeholders such as the contractor, subcontractors, suppliers and clients. Furthermore, is has been established that limited support from governments, consultants, clients and statutory boards does not promote the implementation of JIT [10]:.

Annotated Bibliography

Nielsen, A. S. & Kristensen, E. L. (2002): Paper 3: Lean Construction. En redegørelse for the amerikanske produktionskoncept - Lean Construction - udviklet mhp. en effektivisering og reorganisering af byggeprocessen:

An extensive paper in three parts regarding several aspects of lean construction. The first part gives a general introduction to the background for the development of lean construction. Second part presents the TFV theory, that tries to combine three different views of production. In the third part, practical tools and methods for the transition towards lean construction are discussed.

Ballard, G. & Howell, G. : Toward Construction JIT:

Ballard and Howell strives to identify the differences in the manufacturing- and the construction industry and discusses how these differences complicates the introduction of the Just-In-Time concept into the construction industry. They identify the buffers traditionally utilized in the industry, and they are thought optimized.

Bertelsen, S. ; Nielsen, J. (1997). Just in time Logistics in the supply of building materials. 1st international Conference on Construction Industry Development: Building the future Together. :

A brief description of the framework of how traditionally logistics in the construction industry is viewed. The experiments conducted regarding new ways of organizing the cooperation between the companies which are responsible for the final product - the house, are discussed. The authors introduces the concept of 'Byggelogistik', which is characterized by careful planning, daily management executed from the building site - not the head office - and immediate and direct feed back of all mistakes.

References

- ↑ Ohno, Taichi. Toyota Production System. Productivity Press, 1987

- ↑ “Just-In-time – visioner og erfaringer” , Samfundslitteratur, 1990

- ↑ Wormack, J. P. & Jones, T. D. : Lean thinking: Banish waste and create wealth in your corporation.

- ↑ 4.0 4.1 Ballard, G. & Howell, G. (1994), Implementing Lean Construction: Stabilizing Work Flow. 2nd Annual Conference on Lean Construction at Catolica Universidad de Chile Santiago, Chile September

- ↑ Simonsen, R. (2017): Lean Construction & Last Planner System. Slideshow.

- ↑ Cho, S. & Ballard, G. (2011): Laster Planner and integrated Project Delivery. Lean construction Journal 2011 pp 67-78 .

- ↑ Hammarlund, Y & Rydén, R (1989), Effektivitetet i VVS-branschen, Arbetstidens utnytjande, (1989), Svenska Byggbranschens utvecklingsfond, Sweden.

- ↑ Bertelsen, S. ; Nielsen, J. (1997). Just in time Logistics in the supply of building materials. 1st international Conference on Construction Industry Development: Building the future Together.

- ↑ 9.0 9.1 Ballard, G. & Howell, G. : Toward Construction JIT.

- ↑ 10.0 10.1 10.2 10.3 Sui Pheng, L. & Shang, G. (2011): The Application of the Just-In-Time Philosophy in the Chinese construction industry. Journal of construction in developing Countries.