The procurement process

Each project needs a certain amount of resources. Usually not all of these are already owned or available within the project organization. Therefore, the company will purchase some of the required sources or services from other firms. In a project, the statement of work describe in detail the needed resources. The project team will examine this document and decide which of the items can be found or produced internally and which one to purchase. Once identified the whole resources to acquire externally, these are communicated to the procurement function. The procurement function oversees the search for the best seller for each specific resource or purchase category. For this purpose, buyers and procurement managers start communicating with potential suppliers through exchange of procurement documents. Typically, each document reflects a stage of the buying process. In each stage, the buyer and the vendor require and provide different information. The first contacts between procurement and vendor are aimed to establish the supply scope and expectations. When the process evolves, the communication switch toward specific qualities of the request (and of the offer). These documents are sent to all potential suppliers by different channels, depending by the size of the purchasing and selling company and by their policies. Contractors and buying organization negotiate the contractual form that regulates the provision. The choice of contract typology, from the buyer organization side, has the goal to avoid, mitigate or transfer the risk to the vendor.

Contents |

Verify need to purchase, Make or Buy

The first step of the procurement process is to assess if there is actual need of purchasing. The company could in fact own internally the necessary resource to fulfill the work. However, these resources should not be available in the time and amount defined by the project schedule. If the project organization has no availability of the required means for completing the work before the deadline, it will effectuate a buy decision. In this case, a lease or purchase decision follows to decide if acquire temporary or permanently the assets.

Knowledge source

When the organization states the need for acquisition of external assets, it has to acquire internal and external knowledge about the market and the delivery modes of the needed products.

Experts

Different kind of expertises may contribute in defining the purchase strategy. Experienced buyers are a good source of market knowledge. While the legal department usually guides in defining the clauses and the liabilities that regulate the provision. The internal client, the person or department in the project organization that demands the purchase, communicates qualities and specifications.

Market research and meetings

Market research consist in examining existing suppliers’ capabilities. This can be done by attending sector convention or examining reviews from internet or other buyers. Purchasing objectives can be adapted for leveraging mature technologies. The higher level of knowledge will be acquired through the bidding process by communicating directly with the vendors. We will examine this process in the following sections.

Definition of the required items, Statement of work

The statement of work (SOW) is a document that summarizes the task and the target to fulfill in a project. The SOW is settled from the project scope and defines the part of the project scope to include in the supply contract. A procurement SOW is comprehensive of detailed information about[1]:

- Goals and motivation, why the project was started

- Scope, detailed description of what is (and what is not) included in the project

- Deliverable, what must by achieved in the project

- Quality, standard and metrics adopted to guarantee the quality of the project output

- Resources, Materials, Personnel and Financials necessary to complete the project

- Schedule and Cost, of the the project over its lifetime

- Target, how the success of the process will be measured

- Period of performance, start and end date of the project

The procurement SOW includes also an overview of the collateral services required, such as performance reporting or post-project operational support for the procured item. In some application areas, there are specific content and format requirements for a procurement SOW. The procurement SOW can be revised and refined as required as it moves through the procurement process until incorporated into a signed agreement. Essentially, the SOW includes all the information on the needed items in relation with the project characteristics. By examining it, a potential seller should be able to asses if he can, or cannot, provide the required products or services.

Identifying the supplier

When a company is about to start a new project, one of the first activities is to estimate the needed resources. Documents as activity list and activity attributes give an overview of all the necessary resources. If the company has no similar projects in his portfolio,it is likely that the procurement has no contact with the companies providing product and services required by the project. For this reason, the first document that the procurement function issues is a request for information.

Mapping of the market, Request For Information (RFI)

The main purpose of RFI is to gather information about potential suppliers. This is particularly helpful if a single or few contractors are expected to provide a large amount of services and materials in a single project. RFI can be very beneficial in scanning the market for product and services providers for long-term supply agreements. The Internal client, the person or business unit requiring the purchase, is responsible to provide the technical specification or to write the Request for Information itself. The document is received by the procurement function that is appointed to make it available to potential suppliers.

The document is published, or sent to a broad base of potential supplier, on the channels defined by the buying company policy. For many suppliers replying to RFI is a chance to promote their product and services. Consequently, companies may includes special incentives and discount prices in their quotations[2]. By responding to a request for information a business is showing its interest in meeting the needs of the company that sent out the request. Procurement may use RFIs to list the products and services to require a first quotation. The pricing obtained at this stage is used to assess the different companies price level. This information can be used later in the negotiation phase and should not be considered for buying decision. The quotation provided at RFI level will not necessary reflect the final ones, as suppliers will redefine it as they get more information. Through analysis of RFI: responses, strategic options, lower cost alternatives, and cost reduction opportunities may be identified. The different vendors that reply to the request are inserted in a database. This is used for future supplier negotiations on the quality and price of the supply.

Aligning buyer and supplier expectation, Request For Proposal (RFP)

The main outcome of the RFI is a first overview of potential suppliers. At this point, the procurement communicates its willingness to consider a partnership and states the availability of funds. This is done through a request for proposal. The RFP states the bidding process and contract terms, and provides guidance on bidding form and process. The request describes the solution that the company requires and the criteria on which each proposal is graded. Requests for proposals can include a statement of work describing the tasks to be performed by the winning bidder and a timeline for providing work or material. An effective RFP also contains information about the supplier profile, as this should be compatible with the buying organization objectives. A request for proposal for a specific project may require the company to review the bids to not only examine their feasibility but also the health of the bidding company and the ability of the bidder to actually do what is proposed[3]. The structure and format of the response is to the discretion of the suppliers. The originality supplier shows in building their proposals may be used to distinguish one from another.

Benchmarking and selection, Request For Quotation (RFQ)

Once a range of suppliers is available, buyers aim to collect more precise information to make a comparison between the different offers. To make this possible procurement sends a Request for Quotation to all the suppliers that displayed interest in RFI's answer, or to those that are already present in the database. Better supply quality is most likely achieved when procurement sets specific parameters and defines relevant specifications. Consequently, the RFQ should contain a detailed list or description of all relevant parameters for the intended purchase. All the potential suppliers replies by following a defined framework including information such as[4]:

- Personnel skills, training level or competencies

- Part descriptions/specifications or numbers

- Quantities/Volumes

- Description or drawings

- Quality levels

- Delivery requirements

- Term of contract

- Terms and conditions

- Other value added requirements or terms

- Draft contract

If this is done correctly, it will be easier to compare the goodness of the quotation of the different firms. The offers replying an RFQ is received in many case in the form of a sealed bid, in one or more submission rounds. All the answer to the RFQ are evaluated by the same criteria. Essentially, key parameters will represent hard constrains. For instance, external IT contractors hired from a consultancy firm will be required to have specific competences and know particular programming language. All the offers that does not respect these constrain will not be considered. If the item purchased is a commodity, price per item or per unit of service can be the main evaluation criteria, otherwise it will be considered the trade off between the quotation and the other parameters. The procurement department makes the final supplier decision following a comparison and analysis of the RFQ responses for negotiation benchmarking advantage.

Get the best available provision, Request For Tender (RFT)

Purchase of extended of large amount of products or services may require a tender. A tender is published the channel determined for the purpose by the company purchasing policy. Larger companies has their own platforms or employee third parts tender platform[5], others publish the tender on public newspapers, trade journals, public registries, or on the internet. The RFT contains well defined specification for the requested item. The level of detail of RFT should mirror the one of the RFI's answer. Sometimes the buying organization makes available ad-hoc forms that the bidders must fill and submit to participate in the tender. If the buyer misses to specify exactly what his organization need, the quality of the resulting bids will be affected by the supplier interpretation of the request. Tenders are an appropriate tool when requirements of products or services is known with satisfactory advance, compared to their actual use period (defined in the project schedule).

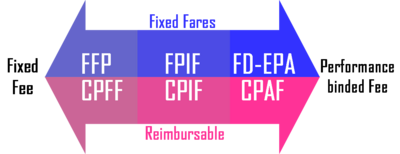

Contract categories

Once the buyer (or the project team in absence of a procurement function) has identified the most appropriate vendor, the two parts sign an agreement. Skilled procurement professionals are able to negotiate the best contractual form for their organization. Each contract type spares differently the responsibilities of the two parts. Also the remuneration criteria for the contractor differs between agreement categories. Companies have different policies about who will sign the contract on the company’s behalf. Some policies defines a maximum contractual value that each buyer can sign for. There exists three main categories of contracts used in supply agreement:

- Fixed-Price contracts

Fixed-Price contracts assign a fixed total price for the provision of products of services. This type of agreement can include financial incentives when some target performance of quality or schedule are achieved. The contract binds the supplier to provide all the items agreed, penalties are applied if the terms are not respected.

- Cost-reimbursable contracts

In cost-reimbursable contracts the client refunds the seller for the cost sustained over the project. In addition, the customer will provide the supplier with a fee, representing the vendor’s profit. The contract may include clause for financial reward in case of outstanding expenditure or time performance.

- Time and material contracts

Time and material contracts are used when it’s know the typology of, material or staff that must be outsourced, but is not know the amount, needed or the time horizon of the provision. They are particularly,useful to employ external staff for a defined period.

The table shows a synthetic overview of the types of contract present in the three categories:

| Type | Name | Description |

|---|---|---|

| Fixed-Price contracts | Firm Fixed Price Contracts (FFP) | The price for the good is set by the vendor, and once the contract is signed, it cannot be changed. The only cases in which the price can vary is when the scope of the project is revised or when the client requires different specification from the one stated in the contract. |

| Fixed Price Incentive Fee Contracts (FPIF) | FPIF contracts allows a degree of flexibility on the cost of the item. This flexibility is linked to the supplier performance in delivering the item. Performance target are settled by the vendor, and they relate to time, schedule and technical performance. The cost of the supply is billed when the work is finished. In this way, the client recognizes the supplier financial incentives in case of outstanding performances. However, the cost cannot exceed a price ceiling. The supplier must cover all the costs surpassing that threshold. Vendors are also legally liable for the completion of the work. | |

| Fixed Price with Economic Price Adjustment Contracts (FP-EPA) | FP-EPA contracts are designed for long term supply agreement.,These,contracts are usually valid for many years. For this reason, the fixed,price is adjusted on the base of precise indicators. Indicators involve,variation on the price of commodities and financial index aimed to,identify inflation changes. These adjustments defends both buyer and,vendor from adverse scenario change. | |

| Cost-reimbursable contracts | Cost Plus Fixed Fee Contracts (CPFF) | The vendor is reimbursed for all the cost sustained in the provision.,Additionally, he receives a fee computed as percentage of initial,estimated project cost. The fee does not depend by the seller,performance but is revised in case of scope changes. |

| Cost Plus Incentive Fee Contracts (CPIF) | In CPIF the seller is reimbursed of all allowable costs sustained for,completing the work. Furthermore, he receives a fee that can vary,depending by the achievement of performance objectives set in the,contract. Cost higher or lower cost compared to the budget are shared by,vendor and buyer according to formulas defined in negotiation phase. | |

| Cost Plus Award Fee Contracts (CPAF) | The vendors is reimbursed of sustained cost. The fee is based solely on,performance achievement stated in the contract. The fee is defined by,the buyer on his perception of the seller performance. Fee definition is,not subject to appeals.

This type of contract can be signed by contractors that wants to gain a,good reputation with the customer as tie the profit to the quality of,the work delivered. | |

| Time & Materials | The contract,defines the unit price for the specific item, for example daily wage of,an expert or a unit of material, but it does not state the amount.,Therefore, the cost of the contract is billed to the buying organization,on ongoing basis, depending by its usage of the resources stated in the,contract. | |

Purchase Orders

When a company need to purchase commodities on recurring basis, the term and conditions of the trade are negotiated by the two part and then stated into a framework agreement. In this way, all the future purchase of the item listed in the agreement will be regulated by it. When this agreement is in place, the buyer can release a purchase orders (PO), a document containing the types and the amount of purchased goods or services. When the supplier accepts it, the purchase orders becomes a legally binding document. For that moment the buying organization will be liable to pay for the supply. Once the vendor receives the payment, he releases an invoice. This can be used by the buying company for controlling purpose by making it match with the corresponding PO.

Risk and pitfalls

As many other project management activities, procurement's activities include several risk and pitfalls.These can involve the internal procurement process, the definition of supply specifications and delivery modes or lack of strategic prospective.

Meet requirement for negotiation time

Not always the required purchases are available in project planning documents. Many times, internal clients manifest the need to acquire external capabilities with little or no advance to the procurement. In this case, buyers have little bargaining power toward any potential seller as there is no time for an effective negotiation. As result, should be responsibility of the interested business unit or process owner to communicate the buying decision to the procurement. Only in this way is possible to achieve buying performance through negotiation.

Get what is needed

In many procurement categories, especially the services one, it is particularly challenging to define what is needed. Contracts always state the duration of service provision but not always are clear about how the service is delivered and what services are included. To overcome the possibility of lacking service level, buyers should negotiate with vendors the inclusion of service KPI into the contract. This is usually the case for IT service on Cloud where uptime is an essential metric. The solution is identifying the metrics that characterize the service as ensure they are included and set in contracts.

Define pricing policies

Another arising issue of IT service contract is the vagueness of pricing over time. Many services are offered at favorable initial prices. Companies can be tented to subscribe for the services. However, if buyer fail to negotiate a long term pricing profile suppliers will have the chance to increase billing prince extensively[6]. Service providers can make leverage on the technical lock up and the switching cost for increase their revenue.

Supply relationship management

Supply relationship management is the activity of connecting the interest of the organization and its extended supply chain. Tradition supplier relationship between a company and its supplier have tactical of operational prospective. SRM starts with finding the right stakeholders and align strategic objectives. This kind of approach is particularly beneficial for long term supply relationship as it can bring[7]

- Efficiency improvement

- Cost reduction

- Risk mitigation

- Increased potential for innovation

Naturally is not possible to establish this kind of relation with all the supplier. It is necessary to categorize suppliers on their strategic importance to the organization. In this way the focus will be directed only toward the most relevant suppliers.

References

- ↑ http://www.humanwareonline.com/project-management/center/sow-statement-of-work/

- ↑ http://www.method123.com/template--rfi.php#!prettyPhoto

- ↑ http://www.investopedia.com/terms/r/request-for-proposal.asp

- ↑ https://www.negotiations.com/articles/procurement-terms/

- ↑ https://www.ariba.com/

- ↑ http://www.zdnet.com/article/cloud-computing-pricing-beware-the-bill-shock/

- ↑ Deloitte: Supplier Relationship Management (SRM), Redefining the value of strategic supplier collaboration (2015), https://www2.deloitte.com/content/dam/Deloitte/de/Documents/operations/Supplier_Relationship_Management_2015.pdf