Value stream mapping in construction management

| Line 6: | Line 6: | ||

===VSM generic formulation=== | ===VSM generic formulation=== | ||

| − | [[File:ValueStreamMapParts.png| | + | [[File:ValueStreamMapParts.png|350px|thumb|right|'''Figure 1:''' Value stream map.<ref name="wiki-VSM">https://en.wikipedia.org/wiki/Value_stream_mapping</ref>]] |

Value stream mapping (VSM) originated in the manufacturing industry. It was developed by <span class="plainlinks">[https://en.wikipedia.org/wiki/Toyota Toyota Motors Corporation]</span>, being a part of their Lean management tools. The Lean management philosophy is to identify and eliminate every activity in the design, production and supply chain management related processes that does not create value for a costumers point of view<ref name="conference_paper">https://www.researchgate.net/publication/282156168_Implementing_Value_Stream_Mapping_Tool_in_the_Construction_Industry</ref>. Generally it is characterized as a process-improving management philosophy, that seeks to minimize the waste without decreasing the productivity. | Value stream mapping (VSM) originated in the manufacturing industry. It was developed by <span class="plainlinks">[https://en.wikipedia.org/wiki/Toyota Toyota Motors Corporation]</span>, being a part of their Lean management tools. The Lean management philosophy is to identify and eliminate every activity in the design, production and supply chain management related processes that does not create value for a costumers point of view<ref name="conference_paper">https://www.researchgate.net/publication/282156168_Implementing_Value_Stream_Mapping_Tool_in_the_Construction_Industry</ref>. Generally it is characterized as a process-improving management philosophy, that seeks to minimize the waste without decreasing the productivity. | ||

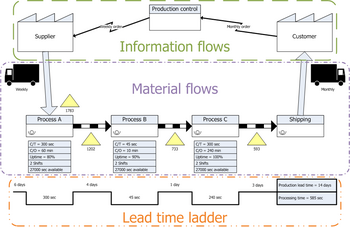

| − | Value stream mapping (VSM) is used to both analyse and design the flow of material and information, that is required to bring a product or service to the end customer. It is a visual tool that provides a holistic view of the overall process, and thus a platform for strategically improvement and adding value to the costumers<ref name="master_thesis">http://oaktrust.library.tamu.edu/bitstream/handle/1969.1/156276/LI-THESIS-2015.pdf?sequence=1&isAllowed=y</ref>. The goal is to design an “ideal state”, also known as the “future state” by analyzing the “current state”. The current state presents how the process is at the time of making the VSM, which is important due to its dynamic nature. The waste present within the work flow system, is identified by reflecting the current state. Having identified the wastes, a future state can be designed where the wastes are eliminated. VSM generates security within the organisations, which is essential to success. Insecurity often result in withhold of important information about the flow and processes, and will consequent lead to delay and loss of value. The general mapping of a current state is presented in '''Figure 1''', showing the three key points: | + | Value stream mapping (VSM) is used to both analyse and design the flow of material and information, that is required to bring a product or service to the end customer. It is a visual tool that provides a holistic view of the overall process, and thus a platform for strategically improvement and adding value to the costumers<ref name="master_thesis">http://oaktrust.library.tamu.edu/bitstream/handle/1969.1/156276/LI-THESIS-2015.pdf?sequence=1&isAllowed=y</ref>. The goal is to design an “ideal state”, also known as the “future state” by analyzing the “current state”. The current state presents how the process is at the time of making the VSM, which is important due to its dynamic nature. The waste present within the work flow system, is identified by reflecting the current state. Having identified the wastes, a future state can be designed where the wastes are eliminated. VSM generates security within the organisations, which is essential to success. Insecurity often result in withhold of important information about the flow and processes, and will consequent lead to delay and loss of value. |

| + | The general mapping of a current state is presented in '''Figure 1''', showing the three key points: | ||

*Information flow | *Information flow | ||

*Material flow | *Material flow | ||

| Line 16: | Line 17: | ||

===VSM in the construction industry=== | ===VSM in the construction industry=== | ||

| − | [[File:ManvsCon.PNG|300px|thumb|right|Figure 2: Construction industry vs. Manufacturing industry.<ref name="8_waste_types">http://c.ymcdn.com/sites/www.nasfa.net/resource/resmgr/Learning_Series/Intro_to_Lean_Construction_&.pdf</ref>]] | + | [[File:ManvsCon.PNG|300px|thumb|right|'''Figure 2:''' Construction industry vs. Manufacturing industry.<ref name="8_waste_types">http://c.ymcdn.com/sites/www.nasfa.net/resource/resmgr/Learning_Series/Intro_to_Lean_Construction_&.pdf</ref>]] |

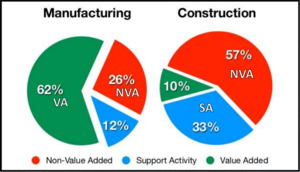

The construction industry in terms of productivity, quality and efficiency, is often characterized as a backward industry, that fails to innovate compared to other industries. The Lean Thinking philosophy was adopted to the construction industry since the 1970's, and several successful implementations has been achieved. The Construction | The construction industry in terms of productivity, quality and efficiency, is often characterized as a backward industry, that fails to innovate compared to other industries. The Lean Thinking philosophy was adopted to the construction industry since the 1970's, and several successful implementations has been achieved. The Construction | ||

Industry Institute states that only 10% are value added inputs and striking 57% are waste. This is compared to the manufacturing industry where 62% is value added and 26% is waste. The lack of performance in the construction industry compared to other industries, has been directly related to the low rate of innovation<ref name="master_thesis">http://oaktrust.library.tamu.edu/bitstream/handle/1969.1/156276/LI-THESIS-2015.pdf?sequence=1&isAllowed=y</ref>. These statistics are a major motivation, for studying and identifying the wastage, which is frequently present in the industry. Consequently how to apply Lean tools and techniques to reduce the wastage. Examples of value adding activities are pouring concrete, erecting steel pr installing the roof. Examples of waste are excessive material handling, design errors, conflict between contractors, ineffective supply chain and rework. | Industry Institute states that only 10% are value added inputs and striking 57% are waste. This is compared to the manufacturing industry where 62% is value added and 26% is waste. The lack of performance in the construction industry compared to other industries, has been directly related to the low rate of innovation<ref name="master_thesis">http://oaktrust.library.tamu.edu/bitstream/handle/1969.1/156276/LI-THESIS-2015.pdf?sequence=1&isAllowed=y</ref>. These statistics are a major motivation, for studying and identifying the wastage, which is frequently present in the industry. Consequently how to apply Lean tools and techniques to reduce the wastage. Examples of value adding activities are pouring concrete, erecting steel pr installing the roof. Examples of waste are excessive material handling, design errors, conflict between contractors, ineffective supply chain and rework. | ||

====8 types of waste in the construction industry==== | ====8 types of waste in the construction industry==== | ||

| − | [[File:8 wastes.PNG|300px|thumb|right|Figure 3: 8 types of waste<ref name="8_waste_types">http://c.ymcdn.com/sites/www.nasfa.net/resource/resmgr/Learning_Series/Intro_to_Lean_Construction_&.pdf</ref>]] | + | [[File:8 wastes.PNG|300px|thumb|right|'''Figure 3:''' 8 types of waste<ref name="8_waste_types">http://c.ymcdn.com/sites/www.nasfa.net/resource/resmgr/Learning_Series/Intro_to_Lean_Construction_&.pdf</ref>]] |

The following table list the 8 types of waste, typically found within the construction industry<ref name="8_waste_types">http://c.ymcdn.com/sites/www.nasfa.net/resource/resmgr/Learning_Series/Intro_to_Lean_Construction_&.pdf</ref>. | The following table list the 8 types of waste, typically found within the construction industry<ref name="8_waste_types">http://c.ymcdn.com/sites/www.nasfa.net/resource/resmgr/Learning_Series/Intro_to_Lean_Construction_&.pdf</ref>. | ||

Revision as of 20:10, 12 June 2017

Value stream mapping (VSM) is a tool used within the field of Project Management to visualize and improve the overall flow process of a product or service from raw material all the way to the customer. It has its origin at TOYOTA, being a part of their lean management tools, where it is known as “material and information flow mapping”. VSM helps document all the activities required to complete a request from a customer. It includes people who normally manage individual functions or processes, and makes the overall flow of material and information across the entire process visible. In addition, it brings alignment to the organization, by involving the people who in fact do the work, and provides a platform for improvement and implementation. VSM is dynamic tool, since its continuously updated as the processes is being improved. VSM differs from the traditional tool; process/flow maps, by having a process focus, rather than a product focus. It provides a holistic view of how thing work, with a costumer perspective. One vital gain from applying VSM, is that it provides a common language when talking about processes, and allowing people to operate solely based on facts.

Contents |

The Big Idea

describe the tool, concept or theory and explain its purpose. The section should reflect the current state of the art on the topic

VSM generic formulation

Value stream mapping (VSM) originated in the manufacturing industry. It was developed by Toyota Motors Corporation, being a part of their Lean management tools. The Lean management philosophy is to identify and eliminate every activity in the design, production and supply chain management related processes that does not create value for a costumers point of view[2]. Generally it is characterized as a process-improving management philosophy, that seeks to minimize the waste without decreasing the productivity.

Value stream mapping (VSM) is used to both analyse and design the flow of material and information, that is required to bring a product or service to the end customer. It is a visual tool that provides a holistic view of the overall process, and thus a platform for strategically improvement and adding value to the costumers[3]. The goal is to design an “ideal state”, also known as the “future state” by analyzing the “current state”. The current state presents how the process is at the time of making the VSM, which is important due to its dynamic nature. The waste present within the work flow system, is identified by reflecting the current state. Having identified the wastes, a future state can be designed where the wastes are eliminated. VSM generates security within the organisations, which is essential to success. Insecurity often result in withhold of important information about the flow and processes, and will consequent lead to delay and loss of value. The general mapping of a current state is presented in Figure 1, showing the three key points:

- Information flow

- Material flow

- Lead time ladder

VSM in the construction industry

The construction industry in terms of productivity, quality and efficiency, is often characterized as a backward industry, that fails to innovate compared to other industries. The Lean Thinking philosophy was adopted to the construction industry since the 1970's, and several successful implementations has been achieved. The Construction Industry Institute states that only 10% are value added inputs and striking 57% are waste. This is compared to the manufacturing industry where 62% is value added and 26% is waste. The lack of performance in the construction industry compared to other industries, has been directly related to the low rate of innovation[3]. These statistics are a major motivation, for studying and identifying the wastage, which is frequently present in the industry. Consequently how to apply Lean tools and techniques to reduce the wastage. Examples of value adding activities are pouring concrete, erecting steel pr installing the roof. Examples of waste are excessive material handling, design errors, conflict between contractors, ineffective supply chain and rework.

8 types of waste in the construction industry

The following table list the 8 types of waste, typically found within the construction industry[4].

| Waste type | Definition/cause | Example |

|---|---|---|

| Inventory | Excess products and material not being processed. | Steel door frames delivered in bundles during steel erection. (Early delivering - just to be safe) |

| Motion | Unnecessary movements by people (e.g. walking). | Early delivery of the steel door frames got in the way of production operation and had to be moved. |

| Defects | Efforts caused by rework, scrap, and incorrect information. | In the process of moving the early delivered steel frame doors, some were damaged. |

| Extra-Processing | More work or higher quality than is required by the costumer. | Some of the damaged doors were repaired, and spending time ordering new doors. |

| Non-Utilized Talent | Under-utilizing peoples talents, skills and knowledge. | Carpenters moved the steel frames to the construction install area. |

| Transportation | Unnecessary movements of products and materials. | New doors has to be delivered on site. |

| Waiting | Wasted time waiting for the next step in a process. | Waiting for the new doors to be delivered. |

| Overproduction | Production that is more than needed or before it is needed. | Due to lack of doors to install, the carpenter began on other tasks too early. |

Application

provide guidance on how to use the tool, concept or theory and when it is applicable

remember a image/list of all the symbols [5]

pre cast concrete Yard example from the conference paper[2]

Limitations

critically reflect on the tool/concept/theory. When possible, substantiate your claims with literature

Annotated Bibliography

Provide key references (3-10), where a reader can find additional information on the subject. Summarize and outline the relevance of each reference to the topic. (around 100 words per reference). The bibliography is not counted in the suggested 3000 word target length of the article.

- ↑ https://en.wikipedia.org/wiki/Value_stream_mapping

- ↑ 2.0 2.1 https://www.researchgate.net/publication/282156168_Implementing_Value_Stream_Mapping_Tool_in_the_Construction_Industry

- ↑ 3.0 3.1 http://oaktrust.library.tamu.edu/bitstream/handle/1969.1/156276/LI-THESIS-2015.pdf?sequence=1&isAllowed=y

- ↑ 4.0 4.1 4.2 http://c.ymcdn.com/sites/www.nasfa.net/resource/resmgr/Learning_Series/Intro_to_Lean_Construction_&.pdf

- ↑ http://www.strategosinc.com/vsm_symbols.htm