Comparison of Certifications for Sustainable Buidlings

Developed by Zandra Llamas

Poor quality in buildings is often caused by bad quality management in the construction process. The consequences of that can go from small mistakes to big and problematic situations. This can, furthermore, lead to additional expenses for the correction of errors that could have been avoided, or to big disasters like an uninhabitable building or a building tearing down. Thus, it is important to consider the different quality management systems that will, from an early stage, guide the project not only to be successful, but also to be completely reliable by using all resources appropriately.

This article mentions the different quality management systems - Inspection, Quality Control, Quality Assurance and Total Quality Management - that should be followed to obtain high-quality buildings. It, however, focuses its attention mainly on third-party certifications for sustainable buildings that compile with the four processes, assuring an output of high-quality sustainable buildings.

Among the most widely used certifications, Leadership in Energy and Environmental Design (LEED) and WELL Building Standard (WELL) play a crucial role. Thus, this report compares them in terms of objective, focus areas, project types, evaluation method and certification process. Results show that both play a very important role in the construction industry because while LEED is focused on sustainable, resource-efficient and cost-effective buildings, WELL is, on the other hand, meant to improve indoor climate and impact human health and wellbeing. Therefore, the connection between both certifications is of complementation rather than exclusion.

Contents |

Introduction

Among the systems of Quality Assurance to identify the procedures of quality management, the third-party ones have now been proven to be the best practice as they follow international standards such as ISO. These systems consist of independent parties that certify the quality of a building. Thus, many independent third parties such as LEED and WELL have emerged in the last 15 years. These certifications are based on Sustainability in Construction and aim to increase the number of sustainable buildings in the world.

LEED certification provides independent verification of a building or neighborhood’s green features, allowing for the design, construction, operation and maintenance of resource-efficient, high-performing, healthy, cost-effective buildings [1].

On the other hand, WELL is a performance-based system for measuring, certifying, and monitoring features of the built environment that impact human health and wellbeing, through air, water, nourishment, light, fitness, comfort, and mind. [2].

Big Idea

Quality Management Systems

Quality can be defined as “the degree to which a set of inherent characteristics fulfils requirements” [3]. One of the objectives of the Quality Management Systems is to make clear that non-conformance in a product is somebody’s fault. Thus, workers are encouraged, reward-based, to take responsibility when achieving high quality. There are four main basic approaches to make sure that high quality has been reached and these act as a complement rather than as an alternative:

- Inspection: physical check.

- Quality Control (QC): management control techniques.

- Quality Assurance (QA): externally accredited procedures.

- Total Quality Management: continuous process improvement.

Inspection

Inspection consists of the “conformity evaluation by observation and judgement accompanied as appropriate by measurement, testing or gauging” [3] and is usually performed by external people, or people who are not responsible for the job. Samples are taken and analysed, which reduces the effectiveness as not all the components are audited. However, it is an important task since it identifies problems to be tackled.

Quality Control

Quality Control is “a part of quality management focusing on fulfilling quality requirements” [4]. and consists of all the actions that have to be followed to reach high quality. Therefore, the product is verified according to the customer’s requirements until the output conformance reaches the desired quality levels. Some of the techniques include testing, inspections and walkthroughs.

Quality Assurance

Quality Assurance can be defined as the “part of quality management focused on providing confidence that quality requirements will be fulfilled” [4] by supplying a set of processes than can be applied to ensure high quality in the output. Quality Assurance can be considered as a Strategy of Prevention as its main focus is to plan, document and set guidelines at an early stage of the project to prevent defects from penetrating into the solution [5]. Thus, engaging with QA already at the starting point of the project is crucial to reduce the risks identified in specification phases.

There are three basic types of QA:

- First-party systems: are responsibility of the company concerned.

- Second-party systems: suppliers are accredited by buyers using proprietary standards.

- Third-party systems: consists of independent and certified third-party systems.

Although the three systems are widely used, the third-party systems are now considered to be best practice as they usually follow the international standards developed by the International Organization for Standardization [4]. Thus, many independent third-parties have emerged in the last years.

Total Quality Management

Finally, the TQM aims for a continuous process of improvement that will lead to higher levels of conformance with the client. It consists of many actions and different processes that will solve one or more non-conformances.

Application

Third-Party Systems

Third-party systems have advantage over first and second-party systems because they consist of an objective audit, not dependent on the company’s or personal interests. Its responsibility is to asses a quality system for conformance compared to the standard and issue the certification of conformance when the quality level is successful.

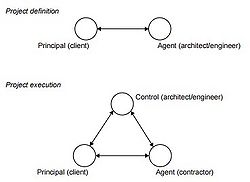

Many parties are included in the project execution, opposed to the project definition where only the client and the agent (an architect or engineer) are involved. In Figure 1, the third-party system for quality control is represented as “Control” and is included only in the project execution.

Since the third-party systems are the most frequent practice, many independent third parties such as Leadership in Energy and Environmental Design (LEED) and WELL Building Standard have emerged.

As mentioned before and contrary to QC, QA , the process of managing for quality is not used to verify the quality of the output [5]. However, LEED and WELL are complete quality management tools because they focus on inspection, management of processes, quality verification of the output, and continuous process of improvement. Thus, these two certifications are different from what was first thought as third-party certifications because they are also included in the Project Definition (refer to Figure 1).

LEED

One of the most widely used third-party certifications in the United States buildings is LEED, which stands for Leadership in Energy and Environmental Design and has been managed by The U.S. Green Building Council (USBGC) since 2000. LEED not only focuses on the design and construction, but also gives considerable importance to the operation and maintenance areas.

Objective, Focus Areas and Project Types

The overall goal is to ensure resource efficiency by using less water and energy and reducing greenhouse gas emissions. Thus, as a side effect and bonus, it also contributes to saving money in both construction and operation.

LEED is organized to promote action in 6 key areas which are also known as credit categories: Location and transportation, Sustainable sites, Water efficiency, Energy & atmosphere, Material & resources, Indoor environmental quality and Innovation.

These categories exist to help clients understand what a LEED project should accomplish (Figure 2):

LEED addresses to buildings everywhere, of any kind and at any phase of development because they have certifications for:

- Building Design and Construction: new constructions or major renovations.

- Interior Design and Construction: complete interior fit-out.

- Building Operations and Maintenance: improvement work or little to no construction.

- Neighborhood Development: land development projects (residential).

- Houses: single family houses.

Evaluation Method

Projects that are aiming to get LEED certification earn points in several areas that are meant to address many sustainability issues. The following are the aspects that are considered when applying for the final certification:

- LEED prerequisites: minimum requirements that all buildings must achieve to acquire a LEED certification.

- LEED credits: several credits from different sustainable areas that can be chosen by the project holder to earn points. The areas are the same as mentioned in the former section.

- LEED points: earned by the chosen credits that are addressed in the project.

Based on the earned points and according to LEED’s rating levels, a project may get one of the following certifications:

- Certified: 40-49 points.

- Silver: 50-59 points.

- Gold: 60-79 points.

- Platinum: 80+ points.

Certification Process

From the list of prerequisites, perhaps the most crucial one is the necessity of commissioning by a certified LEED AP (accredited professional). Commissioning is a highly effective management method to improve the performance of building systems and equipment. It reduces problems and promotes satisfied building owners because it is a quality based process. This process consists of written documentation of facility planning, physical inspection of all installed equipment and operational performance verification of mechanical electrical systems [8].

The process of commissioning includes the pre-design process as well as the executive design, construction, operation and maintenance. The LEED AP of each project is an independent part of the building team and represents the client’s wishes. He must, however, have experience in all the areas of the construction process, for he works together with the architects, engineers and contractors.

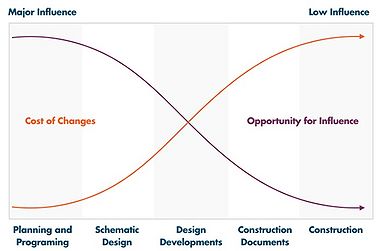

Figure 3 shows the correction costs across the opportunity for influence related to every phase of the construction process. Thus, LEED AP’s goals are to manage the project from an early stage to save the most and to establish strategies to reduce operation costs by focusing on the building’s operation life.

WELL

WELL Building Standard is one of the leading tools that comprehensively address not only the design and operations of buildings, but also how they impact and influence human behaviors related to health and well-being.

Objective, Focus Areas and Project Types

Design and operation of buildings and their impact and influence on human behavior related to health and well-being.

It consists of features across the following seven concepts: air, water, nourishment, light, fitness, comfort, mind and innovation. Thus, all applicable environmental parameters in accordance with WELL will be evaluated. including, for example [10]:

- Air quality (e.g., organic and inorganic gases, and particulates)

- Water quality (e.g., dissolved chemicals and suspended solids)

- Light attributes (e.g., color quality, intensity and spectral power distribution)

- Thermal considerations (e.g., ambient and radiant temperature, air speed and humidity)

- Acoustic elements (e.g., decibel levels and reverberation)

Like LEED, it addresses several types of buildings and can issue certifications for New and Existing Buildings, New and Existing Interiors, Core and Shell, Retail, Education Facilities, Restaurants, Commercial Kitchen and Multifamily Residential.

Evaluation Method

Projects searching for WELL certification go through a similar process as LEED’s. They must compile certain prerequisites or “Preconditions” and earn points in the focus areas by meeting some “Optimizations”.

To earn points, WELL projects go through onsite testing by the WELL AP assigned to the project to ensure they’ve achieved key components of the WELL Building Standard. Testing and measurement during the performance verification are completed according to sampling protocols set by the International Well Building Institute (IWBI) based on the size and project where some collected samples are then sent to a third-party laboratory for analysis.

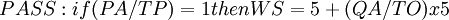

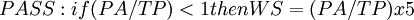

Points are earned and calculated differently than LEED and a minimum of 5 in each section is required. The following formulas are used:

(rounded down to the nearest whole number)

(rounded down to the nearest whole number)

(rounded down to the nearest whole number)

(rounded down to the nearest whole number)

Where:

- Total Preconditions= TP

- Preconditions Achieved= PA

- Total Optimizations= TO

- Optimizations Achieved= OA

- Wellness Score= WS

Table 1 shows a representation of the scoring table used to grade a WELL project:

| Concept | Preconditions Applicable | Preconditions Achieved | Optimizations Achieved | Optimizations Achieved | Concept Scores |

|---|---|---|---|---|---|

| Air | 12 | 12 | 17 | 3 | 5 |

| Water | 5 | 5 | 3 | 0 | 5 |

| Nourishment | 8 | 8 | 7 | 6 | 9 |

| Light | 4 | 4 | 7 | 2 | 6 |

| Fitness | 2 | 2 | 6 | 3 | 7 |

| Comfort | 5 | 5 | 7 | 2 | 6 |

| Mind | 5 | 5 | 12 | 12 | 10 |

| Total | 41 | 41 | 59 | 29 | 7 |

Certification Process

To apply for WELL certification, a project must first be registered online. Basic information as well as the project scope and path need to be provided and Performance Verification must be scheduled. After registration, a WELL AP is assigned to the project by the Green Business Certification Inc. (GBCI) with the responsibility of answering technical questions prior to submission and reviewing the project after the submission.

Then, project team roles are assigned as follows:

- Project Administration acting as a project manager and overseeing the WELL process; responsible for ensuring that all the project documentation is complete and accurate prior to submission

- Owner – responsible for authorizing registration of the project and validating documents

- Additional Signatories – responsible for overseeing relevant aspects of design construction or operation

- WELL AP – guiding projects to successful certification

When the score of any section is <5 it means that the project doesn’t comprise the compulsory Preconditions and the project is disqualified for the certification. The highest score that can be achieved in each section is 10, thus certification achieved depends on the following rating level:

- Silver: 5-6 points.

- Gold: 7-8 points.

- Platinum: 9-10 points.

Limitations

Even though third-party certifications have some advantages over first- and second-party certifications, they also have some limitations or disadvantages. For example, a first-party auditor knows the audited process and he/she interacts better than an external examiner. Moreover, the first-party auditor knows the general ins and outs, thus it’s easier to identify a problem. The internal audit also tends to undergo a deeper analysis of the situation and find more relevant information than a third-party one who tends to be more superficial. Finally, in terms of economy, it is always more expensive to hire an external auditor and thus, it is not always an opportunity for everyone (especially for small businesses and homes).

Annotated Bibliography

- Winch, G. M. (2010). Managing Construction Projects. Iowa: Blackwell Publishing Ltd.

Provides a focused perspective on the role of people involved in construction, especially on project management. One of its approaches is the quality of conformance to requirements, not only product related but also process related. To reach this conformance, quality management systems are used, thus Winch explains further and in detail the different systems that exist. It also provides some Case Studies where the theory is made clear by using real-life examples.

- Arthur, B. (2017). The Difference between Quality Assurance and Quality Control. Retrieved from https://www.dialog.com.au/open-dialog/the-difference-between-quality-assurance-and-quality-control/

Describes the characteristics of Quality Assurance and Quality Control, and explains the connection and differences between both. They are considered to be strategies applied at different stages of the project, and Arthur describes this in a very clear way. It also discusses the benefits of applying these strategies at the right moment.

- LEED, U. G. (2017). Leadership in Energy and Environmental Design. Retrieved from http://leed.usgbc.org/leed.html

Shows a very detailed overview of the LEED Certification, including its meaning, the reasons to and benefits from choosing LEED, the people that should be involved in the project, categories, steps to follow and more. It serves as a good introduction to the certification and further information can be found in the different sections of type of certified buildings.

- IWBI. (2017). The WELL Certification Guidebook. New York

Guides the user through all the steps that are to be followed to get the WELL certification. It dives into the Project Team’s roles, the documentation requirements, performance verification and the final report. It allows the reader to have a clear picture of how to achieve the award and continue with the health engagement in the future.

References

- ↑ LEED, U. G. (2017). Leadership in Energy and Environmental Design. Retrieved from http://leed.usgbc.org/leed.html

- ↑ Knox, N. (2015). WELL Building Standard. U.S. Green Building Council. Retrieved from http://www.usgbc.org/articles/what-well

- ↑ 3.0 3.1 3.2 Winch, G. M. (2010). Managing Construction Projects. Iowa: Blackwell Publishing Ltd.

- ↑ 4.0 4.1 4.2 ISO 9000. (2015).

- ↑ 5.0 5.1 Arthur, B. (2017). The Difference between Quality Assurance and Quality Control. Retrieved from https://www.dialog.com.au/open-dialog/the-difference-between-quality-assurance-and-quality-control/

- ↑ Owens, B. (n.d.). LEED v4 Impact Category and Point Allocation Development Process.

- ↑ Mandelbaum, M. (2014, 10 09). Percolate, Applying Architecture to Product Design. Retrieved from https://blog.percolate.com/2014/10/applying-architecture-product-design-lesson-2-program/

- ↑ Commissioning Solutions. (2017). Retrieved from http://www.commissioningsolutions.com/what-is-commissioning/

- ↑ 9.0 9.1 9.2 IWBI Standard. (2017).The WELL Building Standard. Retrieved from https://standard.wellcertified.com/

- ↑ IWBI Guidebook (2017).The WELL Certification Guidebook. New York