Lean principles in the construction industry

The construction sector is one of the main pillars of economic growth and country development for all nations across the globe and a link in the chain of dependencies between all industries in terms of consuming inputs and providing products. Nonetheless, it is estimated that 50% or more of the required resources and effort as to deliver the built environment consists in waste, or non-added value effort from the customer's perspective. The same lack of effectiveness of the labor hour in the past 50 years has caused for the construction industry to fall behind in the terms of major advancements while the other industries continue to expand and develop. Over time, the workforce landscape has also changed due to demographic and labor shifts, reducing the labor availability and consequently increasing the relative cost of a built environment. [1]

Lean construction is a robust approach that attempts to reduce waste in the construction projects, enhance performance and cut down cost for the industry and the society at large. [2] The concept first emerged in the 80's after gaining full acceptance in the West due to the major improvements displayed in the manufacturing operations and has its roots in Toyota's production management principles. [3]

Essentially, it aims to meet the same value creation criteria as the classical project management, meaning project delivery within time and budget and the production of a building according to the customer's requirements which concurrently contributes economically and socially to the area. The core novelty of this methodology, according to the Lean Construction Institute, comes from the replacement of monitoring results throughout the project execution with a solid planning phase and its continuous learn-improve loop. This should assure a certain level of system performance that sustains a reliable workflow and controllable outcomes. Another difference comes from the focus on minimizing waste and maximizing value at a project level and the use of concurrent engineering to prevent wasteful redoes.

This article showcases how implementing the Lean project practices in construction firms is a continuous process of learning and enactment, involving both internal and external actors. In this sense, it analyzes how the construction projects differ from the manufacturing operations and how that affects the Lean principles' migration. Subsequently, it discusses what limitations need to be considered before seeking to include elements of this methodology in the planning phase and ultimately what are some recommended directions and techniques that can be included with the final goal of reaching sustainable organizational change. As a successful implementation case does not yet exist in the industry and many fundamentally different attempts had been made and researched on, the article proposes a model that should fill in the gaps and aid any interested practitioner in this endeavor.

Its structure will take the reader through a brief history of the concept by presenting the Toyota story, the takes from it and the key differences between manufacturing and construction projects, the five traditional core principles of the Lean management and the waste sources in the targeted projects, implementation directions and limitations.

Contents |

Big idea

History

The concept of Lean stems from Toyota's Lean production, also known as Toyota Production System (TPS), which fundamentally applied precast construction principles to their manufacturing processes with the end goal of creating a leaner organization.

The Toyota Motor Corporation is a prominent player in the automotive industry, alongside with other widely known automakers such as Ford Motor Company and General Motors Company. What had made their production methodology an attractive research target is its massive impact on their profit, production output and sales volume and, consequently, their competitive advantage since it was founded.

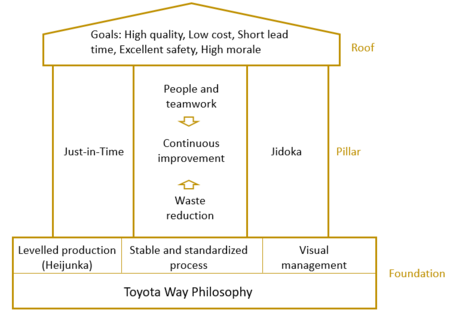

The core concepts of TPS and their intercorrelation can be visualized in a structured manner through the TPS house, consisting of two pillars supporting a roof and a foundation. A good understanding of this is essential for developing and improving a lean system which will subsequently aid the company in removing waste and non-value adding effort, resulting in increased efficiency and maintenance of superior value and quality. [4]

As it can be observed, the procedure puts much emphasizes on the supply chain's speed. The underlining trend is to shorten the lead time by reducing or completely eliminating waste at each step in the process to produce the best quality, at a low cost, delivered on-time, while also enhancing safety and morale, principles known as QCDSM. [5] The techniques and procedures can be further researched on in the indicated article in the Annotated Bibliography section.

Nonetheless, a successful implementation of TPS requires more than adopting and applying a set of tools, methods and techniques. It demands a pervasive and intensive cultural transformation at a company level and the development of a strong collaborative relationship with the suppliers, which will lead to quality materials being delivered consistently and productively. Toyota itself took decades to instill this, and its improvement is still possible.

Lean core concepts and principles

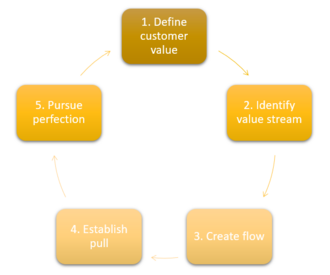

Toyota's methodology was subsequently disseminated and researched on by multiple authors, Womack and Jones proposing 5 core principles [6]:

- Value: defined through discussions with the ultimate customer. The complexity of identifying it increases in construction projects where there is not a single ultimate customer, but the construction client and multiple end customers alongside to be taken into consideration. Additionally, understanding the customer's needs implies both defining the end product or service and the preferred procedure for obtaining it.

- Value stream: analyzes three types of actions - activities that generate value, non-value adding activities which remain unavoidable due to current technological and production constrains and non-value adding activities that can be avoided.

- Flow: after reducing or completely eliminating waste, all the remaining steps of every process need to flow, so the product can be delivered from concept to client without delay or interruption. This involves eliminating batch and queue, and some recommended methods are restructuring the production, training the employees to be skilled in multiples areas and adaptive, delegating the workload to more than one asset.

- Pull: close to TPS's original pull system, this principle aims to tailor the production to the customer's requirements in terms of quantity and delivery time and save inventory space and materials in the process.

- Pursue perfection: through the application of the previous four principles in a continuous loop, the company can identify and reduce hidden waste, highlighting the need to adopt the Lean principles as an integrated part of the work environment.

The relation between these steps can be visualized in Figure 2.

In essence, Lean production takes place at both a strategic and an operational level. Strategically, it equips the organization with a structured approach of defining the customer value and identifying the value stream and, at an operational level, it provides multiple tools and practices for eliminating waste and integrating permanent improvement.

From manufacturing operations to construction projects

Fundamentally, transferring these Lean principles from the manufacturing production to the construction industry has its limits since the two domains operate on different grounds. The manufacturing processes are performed in a factory-controlled environment in which the production line follows a clear flow with easy to identify steps and constraints, there is a mass-produced with little variation output and minor fine-tuning from one project to another.

Whereas the construction projects involve a much higher level of complexity as each one of them presents a unique frame of physical, social and environmental traits. Moreover, the planning phase takes into account a more dynamic context, as opposed to the previously described isolated system, with often concurrent activities that need to be scheduled accordingly, with considerations of the weather and required resources. Time is an important constraint that does not leave space for errors in the allocation of different types of professionals as the construction is time bound and generates additional cost if the date for completion is overdue. The learning curve opportunity is also missed in most cases because the workers change frequently.

Another distinction between the two fields is the more considerable amount of waste generated by the construction industry. Traditionally, waste can be defined as non-value adding activities for the final output, meaning activities that consume time, money, material resources and manpower and bring no value to the ultimate customer.

Although the focus usually lies on the material waste, Ohno [7] described 7 types of waste. An overview is provided for understanding the full implications:

- Overproduction (unnecessary work): The production of a greater than necessary amount with the aim of building up the inventory or keeping the equipment running and attaining outstanding resource utilization. Done on a continuous basis, it causes quantity and quality problems, and it is difficult to identify without making a deliberate comparison between what is being produced and what is being sold and shipped. The usage of the mistake proofing approach and an extensive understanding of the production machines' capacities are recommended for addressing it.

- Time on hand/waiting (delays): Commonly described as idle time, it is easy to identify when the products are not being processed or moved, and it refers to the intervals spent waiting between processes/activities for different resources to become available. A possible solution is to create a sustainable flow.

- Inventories (storage waste): Stocking inventory causes monetary loss as the capital is being tied up and the space is occupied with materials susceptible to being inadequately stored on the site, deteriorated, stolen or vandalized. The issue stems from companies ordering more materials than required to fulfill an order as a direct result from an insufficient resource planning and/or uncertain quantity estimation.

- Transportation (materials movement): Mostly visible in the construction projects where resources need to be processed or moved inside of the construction site and it can be attributed in most of the cases to the layout of the working environment or to a lack of process flow, which results in multiple starts and stops in the transportation process and their correlated cost and waste of working hours, energy, space on the site. A method for addressing it is to map a more optimized site layout.

- Movement: This type of waste stems from the way the resources and equipment are being placed around the site by the employees during the working hours which leads to more unnecessary motion, time and effort to perform tasks. The same inadequate site layout or the lacking work methods and insufficient equipment might be its root cause. An additional consequence is the increased rate of accidents and injuries and associated cost. Identifying and redesigning the jobs that produce this type of waste would reduce motion and cost.

- Over processing: It is described as additional processing of the product beyond the client's requirements which does not add further value from his perspective. A concrete example can be seen in the surface finishes. The waste of workforce potential falls under this category as well when the opportunity of making efficient use of their skills and knowledge is missed. Corrective measures consist of applying tools and methods such as the 5 whys and statistical process control or shifting the equipment used for construction.

- Defective products (unsatisfactory work): It occurs when final or intermediate products do not rise to the quality specifications and requires rework or the usage of poor quality materials. Reasons for which these rejects happen are numerous, some of them being improper integration between the design and production phases, loose planning and/or control, unqualified workforce. Mitigation directions include methods for their identification and removal such as the six sigma.

Lean construction

There are multiple perspectives in literature on what the Lean construction concept means, but this article will focus on the wide understanding that it is the application of the Lean production principles and methods in the construction industry, with the Last Planner approach as a widely known example. Moreover, summarizing from the previous section, the two industries have different implications, therefore, a direct transfer of these principles is not possible without a considerable effort in changing the culture and management tools of the construction industry.

Similarly to Lean production, it promotes the timely delivery of projects, within the allocated budget and with the production of the demanded quantity and quality, and its techniques have the potential to remove unpredictability and enhance the ability to handle complexity and uncertainty.

Application

Although Lean construction is still in its early phase in terms of development, there is a set of principles that has been proposed, implemented and tested, and this section is going to cover them, together with widely known tools and techniques that have been successfully adapted or inspired from Lean production. Nonetheless, the aim is to obtain a lean culture, not the fragmented usage of tools and techniques to increase the project performance.

Implementation framework

The aim of the proposed approach is to facilitate the adoption of the Lean methodology as a new business model, as described by Arbulu and Zabelle [8]. The absence of an entirely successful implementation case has at its root the intrinsically different business philosophy that Lean construction introduces. The clash with the existing business approach from the construction industry makes it challenging to perform the transformation and turns it into a business problem rather than an issue with applying tools and techniques.

An organization can typically be seen as a mix of core elements, such as culture, structure, values, people and systems. The transformation process targets this configuration with the goal of changing the current way the organization operates by redesigning the characteristics of these elements, so a lean project delivery and competitive advantage become possible. In other words, it takes the company from a current state to an envisioned future state.

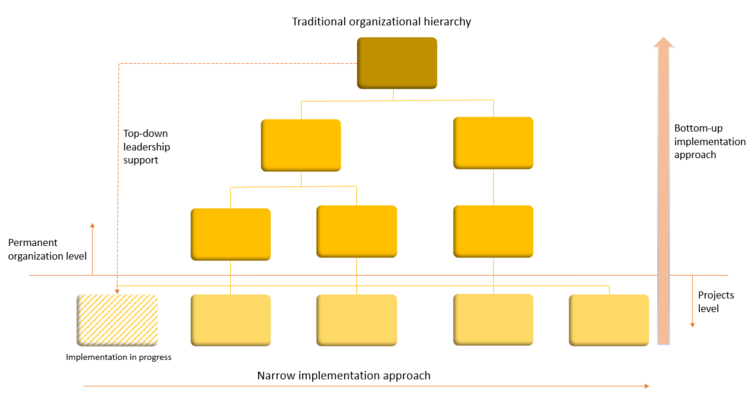

As opposed to the wide top-down transformation approach that is most commonly adopted in which the leadership takes the decision of going Lean without solid and consistent stakeholder engagement, by applying it to more than one project at a time and setting the initiative to failure, a narrow bottom-up model will be described.

Contrary to the first impression, the construction industry holds a key advantage over the other industries when it comes to a sustainable transformation approach, that being its projects. They have the potential to simulate a viable environment for creating a new business model based on the opportunity they provide for designing and implementing temporary business systems. Inside the project setting, the organization can have a clearer view on the performance assessments and monitor what changes should be made on the structure, processes etc. Done on a continuous loop (by taking one project at a time), it will enable the disconnection from old systems, a more fine-tuned process flow, the provision of more well-aligned incentives and a solidly reinforced vision with the committed contribution of the leadership component.

Figure 3 depicts this implementation model, which suggests that the transformation occurs bottom-up from the projects level (the temporary organization) to the main headquarter (the permanent organization) with the top-down leadership support. It takes one project at a time, treats it as a sandbox environment for simulating the new business model, documents the findings and learns how to improve the methodology in the next project.

To support this process inside the project environment, there are 5 elements that significantly impact a sustainable transformation, which need to be met before even attempting to engage in this endeavor, otherwise the likelihood of failure increases:

- Vision: The lack of a clear vision statement will lead to stakeholders' confusion. Therefore, defining what must be accomplished, how it is to be accomplished and what are the success criteria will align all parties' understanding and expectations. Moreover, it will aid the top management and project leadership in creating an implementation strategy by uncovering where the resistance to change might appear.

- Skills: The absence of solid knowledge from the project team's side installs anxiety in all stakeholders involved in the implementation process as money, time and effort are put in something that might not lead to any result. To counter this, investing in training will fill the gap between the current and the new business models. This training needs to include the management of behavioral development, meaning how to keep under control the resistance to change that arises during a transformation process.

- Resources: Organizational transformation without sufficient resources allocated results in frustration. It must be kept under consideration that it requires training for the team members and coaching for the managers.

- Incentive: If a functional incentive strategy is not in place, the change will happen gradually as the project team starts recognizing the benefits of the new methodology, but it will be taking more time than desired. In this sense, understanding the psychology of motivation is key, as money is not the most effective reward.

- Action plan: Not having a comprehensive action plan will have as a consequence a false start, the project team not having a clear sense of order and direction. This can be avoided by creating a commonly agreed on action plan with the project leadership.

If all the criteria are met and combined with solid project leadership, change has space to occur.

By limiting the environment in which the transformation takes place, the top-down leadership support can have a higher impact as effectively leading the teams through change is key, the current business model under which the company operates can be maintained while also creating a new one and the company can quickly gain competitive advantage by selecting projects that significantly contribute to their revenue to apply the transformation on next. Additionally, the break point between the two business models is easier to identify, meaning the moment when at least 50% of the company's projects are being delivered through the Lean based methodology and make the shift.

Inside the project environment

The new leaner business system that will be created inside the project setting refers to applying a precast construction process based on the Toyota Way's 14 management principles, as described by Ong and Pheng [3]. An account of these will be briefly provided below, and further research in the indicated literature is advised.

1. Envision and empathize the long-term results: Similar to the manufacturing operations, the aim is to identify the dependencies and the waste sources in the precast construction process and improve the overall flow, so a greater level of efficiency is met when providing the clients with what they need, in the demanded amount and within the set date. The scope is not on fine-tuning the individual activities at this step, but simply stabilizing them to support the flow. To remain focused on the long-term goals, the end of the flow is to be mapped first. This will constitute the current state map which explains all the conditions of the precast construction flow and will serve as a basis for the future state map.

2. Create a one-piece flow: With the current state map created, all necessary resources for the identified activities should be made available to fulfill the precast requirements, this full picture of how the resources are being allocated and passed by being known as the future state map. Its purpose is to lay the foundation for a smooth connected flow in the value stream, capable of an efficient production of precast components without limitations. This is also the step at which the individual activities are regulated and improved to produce replicable outputs under any conditions.

3. Establish pull: This becomes possible by precise upfront planning of when and in what quantity all precast components are needed throughout the predetermined activities, so the inventory storage space is kept at its minimum. Nonetheless, a considerable amount of inventory should always be at hand to ensure that the demands can be carried out.

4. Balance and stabilize the available workload: Next comes the leveling out of the workload by consistently allocating the right amount of resources and work force to the available amount of work and avoid having unassigned workers. This is done by first grouping the precast components belonging to the same value stream.

5. Fix problems on the run: Introduce and reinforce the working practice among the employees to ensure that the incoming work and their own outputs are defect free before passing them down to the next activity, especially as the construction activities are the integrated sum of all different subcontractors' effort. Taking corrective measures at the right time prevents system failure.

6. Understand the process and consider alternative solution: This is relevant for planning the precast construction process, and it requires that all stakeholders understand the flow of activities, the identified sources of waste and the available alternatives on the market for making the most optimal decision.

7. Continuously monitor and improve flow: This can be achieved by standardizing tasks, which implies defining them and setting the expected performance and action party. Any deviation from this standard will easily be detected this way. Secondary, complementing the manual work surveillance on site with digitalization will make the efforts of ensuring quality easier to accomplish.

8. Empower and develop the people: As people are the core element of any project, training and investing in them is highly relevant. In this sense, it is important to give them ownership and the opportunity to contribute to the company's goal of obtaining a leaner project setup by challenging them with meaningful work and occasional pressure, so they have the space to come up with solutions to problems they best understand. On top of this, broadening their knowledge and skill set through training enables the project management to deploy the same workers to different types of work instead of hiring new ones or generating waiting time. The knowledge diversity also leads to more creative solutions.

9. Build reliable network with suppliers and subcontractors: As stated before, obtaining a leaner organization requires both a cultural change and a solid network with external actors, such as the suppliers and subcontractors. The focus should be on working with constant partners that apply the same Lean methodology inside their own companies and can productively deliver resources and services.

Limitations

Whereas the implementation of Lean construction practices can bring visible benefits in the construction industry and aid in achieving sustainability, there are a number of hindrances in the process. The most notable ones are the unwillingness of the project partners to embrace change, the lack of knowledge about the Lean construction practices, their complexity in itself and the absence of policies and legislation to support them. Other reasons involve the extensive knowledge and amount of time required to adopt them, the lack of an expert for directing their implementation and financial constraints. [9]

More specific research focuses on how a proper implementation is constrained by the level of commitment from the senior management's side as they have a high impact on the organizational culture and are also responsible for selecting the supply chain assigned to the construction projects. An adequate supply chain for this purpose is one trained in Lean construction. [10]

Annotated bibliography

- Joy Ong, Low Sui Pheng, Lean Construction Implementation, 2021, pg 45-74: The book chapter provides an extensive overview of Lean construction and its origins in Toyota's production management, as well as an ample description of the TPS house's concepts which are recommended to be further researched on. It creates a good bridge between the problems that arise in the two industries and justify why simply transferring the methodology is not possible. Subsequently, it presents a precast construction process shift based on the Lean principles.

- Gao Shang, Sui Pheng Low, From Lean Production to Lean Construction, 2014, pg 27-48: The chapter covers similar topics with the previous one and exposes different perspectives proposed by authors who tried to analyze and make Toyota's success easier to replicate. In the second part, it brings an overview of Lean construction's tools, principles and implementation strategies that have been successfully applied to various degrees.

- Roberto Arbulu and Todd Zabelle, Implementing lean in construction: how to succeed, 14th Annual Conference of the International Group for Lean Construction. Santiago, Chile, 2006: The conference paper proposes a model for increasing the construction companies' likelihood to succeed when undertaking a Lean organizational transformation. This implementation strategy was included and described due to its alignment with the idea that Lean construction is rather a business problem than the simple adoption and implementation of scattered tools and techniques from the manufacturing industry and more directions for applying it through these lenses must be easily available. Additionally, it presents highly relevant concepts about the project leadership side.

References

- ↑ Lean Construction Institute, Lean Construction Defined

- ↑ Richard Hannis Ansah, Shahryar Sorooshian and Shariman Bin Mustafa, "Lean construction: an effective approach for project management", 2016

- ↑ 3.0 3.1 Joy Ong, Low Sui Pheng, Lean Construction Implementation, 2021, pg 45-74

- ↑ 4.0 4.1 Gao Shang, Sui Pheng Low, From Lean Production to Lean Construction, 2014, pg 27-48

- ↑ Liker Jeffrey K, The Toyota way: 14 management principles from the world's greatest manufacturer, 2004

- ↑ James P Womack, Daniel T Jones, Lean thinking, 1997

- ↑ Ohno T., Toyota production system: Beyond large-scale production, 1998

- ↑ 8.0 8.1 Roberto Arbulu and Todd Zabelle, Implementing lean in construction: how to succeed, 14th Annual Conference of the International Group for Lean Construction. Santiago, Chile, 2006

- ↑ Olusegun Aanuoluwapo Oguntona, Clinton Ohis Aigbavboa and Gloria Ndalamba Mulongo, An Assessment of Lean Construction Practices in the Construction Industry, 2019

- ↑ Ruan Ximing, Ochieng Edward, Zuofa Tarila and Yang Miying, An appraisal of lean construction project delivery application of lean construction, 2016