Life Cycle Assessment

Life Cycle Assessment (LCA), is an approach used to analyze the environmental impact of products, services and activities over their entire lifecycles. LCA seeks to identify and quantify any environmental risks involved from extraction to manufacturing to use and eventual disposal and reintegration into the economy.

In the context of Project, Program and Portfolio Management (PPPM), LCA can be used to make decisions about which materials to use, which processes to apply, which organizations to collaborate with based on their environmental performance. A Portfolio Manager could, for example, prioritize a project that has a low environmental impact or invest in a company with an overall better environmental performance compared to the alternatives. Also subjects that are external to a company can find LCA very useful. Stakeholders, including investors, customers and policy makers, can use the information to understand the environmental impact of the products they use to buy or to invest in, in order to make more informed decisions.

LCA can be considered as a valuable tool especially in Project Management (PM), as it aligns to principles and guidelines about PM such as the ones provided by the Project Management Institute. This article focuses on the steps that should be carried out to perform a professional LCA, as well as the applications of LCA in PPPM and the benefits and limitations of such tool.

Contents |

Origins of LCA

The idea of LCA was conceived in the 1960s, when environmental degradation and limitations of raw materials and energy resources sparked interest in finding ways to cumulatively account for energy use and to project future resource supplies and use. This practice sees its roots in studies carried out uncoordinately in the US and Northern Europe regarding packagings, with a focus on energy use and a few emissions. At first, studies were primarly done for companies for internal use, usually without informing styakeholders, since interest in sustainability was very limited to few at that time. One example is an internal study initiated in 1969 for The Coca-Cola Company that laid the foundation for the current methods of life cycle inventory analysis in the United States. This study quantified the raw materials, fuels, and environmental loadings from the manufacturing processes for various beverage containers, in order to compare their impact on the environment and their depletion of natural resources. The aim was to identify the container with the lowest release to the environment and the least impact on natural resource supply. After a stall in the 1970s, it was just during the 1980s and 1990s, when international collaboration and coordination in the scientific community started to take place and universities engaged in working on method development, that the application of LCA spreaded across industry and governments, resulting in an increasing range of products and systems included into LCA studies. The term Life Cycle Assessment was itself coined in 1990 and, since then, this practice has seen a constant increase in both range of methodologies and applications.[2] [3]

Steps to perform an LCA

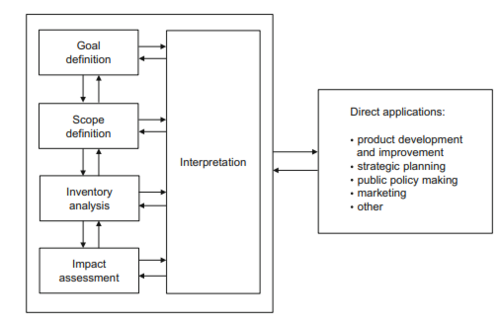

In the following paragraphs are listed the steps that have to be carried out in order to perform a well structured LCA study. These are, as well, the most important parts that must be included in an LCA report that can be considered detailed and professional. The LCA process is a systematic, phased approach and consists of four components: goal definition and scoping, inventory analysis, impact assessment, and interpretation. [5]

Goal and Scope definition

During the goal and scope phase of a study, the objectives are established, including the intended audience, the reasons for conducting the study, and the intended application. This phase involves making key methodological decisions, such as defining the functional unit precisely, identifying the system boundaries, determining allocation procedures, selecting the impact categories to be studied, choosing the Life Cycle Impact Assessment (LCIA) method to be utilized, and establishing data quality requirements.

Functional unit

A lot of attention must be given to the definition of the functional unit, that is the base to calculate all the inputs/outputs of the analysed product and the relative emissions to the environment. The functional unit must be very specific and detailed. An example of functional unit may be : one car of type X, expected to be used for Y years, produced in country Z, with features a,b,c (e.g., how many people it can carry, desired performances etc.).

System boundaries

System boundaries define which life cycle stages are included in the study. In case of a cradle-to-cradle LCA, all the life cycle stages are taken into consideration, from the extraction of raw materials to use phase and disposal. However, in some studies it can happen that some processes are considered to have irrelevant impacts, or that the available data are not enough to model the process, or also, in the case of a comparative LCA, they are considered to have the same impact for both scenarios. Given that, such processes can be excluded from the study, at the condition that the reason of the choice is based on accurate evaluation and well argued.

Impact categories

The impact categories taken into consideration depend on the choice of the authors, that can have more interest in assessing e.g., the impact on climate change rather than on human toxicity. However, the choice of the LCIA method have an influence on that since some impact categories are not included in all methods. The most common impact categories are the following : Climate Change, Eutrophication, Resource Depletion, Land Use, Acidification, Ozone Depletion, Ecotoxicity, Ionizing Radiation, Water Depletion, Human Toxicity, Photochemical Ozone Formation.

Inventory analysis

The Life Cycle Inventory (LCI) phase encompasses the process of gathering and calculating data to measure the inputs and outputs of the system being studied. This includes collecting data on energy, raw materials, products, co-products, waste, emissions to air/water/soil, and other environmental factors. The collected data includes both foreground processes, which are the ones on the direct control of the producer (such as manufacturing and packaging of a product for a consumer good) and background processes (such as the production of purchased electricity and materials for a consumer good). The data is then verified for accuracy and related to the process units and functional unit, and they are the basis for the calculation of the environmental impacts of the product system.

Impact assessment

During the LCIA phase, the results obtained from the LCI are linked to various environmental impact categories and corresponding indicators. LCIA implies multiple steps and calculations, that are normally carried out by the LCA software, such as SimaPRo or GaBi, which also provide the user with a representation of the results in the form of a process tree, a table or a chart. The LCIA phase comprises some steps that are automatically carried out by the LCA softwares, while others are optional and can be applied according to the preferences of the authors of the study.

Classification

Classification requires assigning all the emissions to the relative impact category. For example, all the emissions of greenhouse gases (CO2, Methane, etc.) are associated to the Climate Change impact category.

Characterization

Characterisation involves calculating the magnitude of each input and output towards its respective impact category, and then adding up these contributions within each category. This is done by using substance- or resource-specific characterisation factors that quantify the impact intensity of a substance compared to a reference substance, which allows the calculation of the relative impact category indicator(s). By doing this, all the emissions relative to an impact category are aggregated into one unit of measure. For example, all greenhouse gas emissions are multiplied by a characterization factor that represents in terms of impact intensity relative to carbon dioxide, and therefore represented as an aggregated value of kg CO2 equivalent. The obtained results are called midpoints, which can be further aggregated into 3 areas of protection (AoP), obtaining endpoint results. “Midpoint indicators focus on single environmental problems, for example climate change or acidification. Endpoint indicators show the environmental impact on three higher aggregation levels, being the 1) effect on human health, 2) biodiversity ( or ecosystem health) and 3) resource scarcity. Converting midpoints to endpoints simplifies the interpretation of the LCIA results. However, with each aggregation step, uncertainty in the results increases.” [6]

Normalization

The purpose of normalization is to provide a relative scale for comparing the environmental impacts of different products or processes within the same impact category. By expressing the impact results in relation to a reference unit, normalization enables meaningful comparisons to be made between different LCAs. During normalization, the impact scores are divided by a reference value or factor to obtain a dimensionless score that represents the magnitude of the impact relative to the reference unit. Normalization factors can be based on a variety of sources, including government statistics, multi-criteria decision analysis, expert judgment or stakeholder consultation. The choice of normalization factors depends on the specific impact category being assessed and the availability of appropriate data. According to ISO 14040 standards, normalization is an optional step. However, it can be very useful to visualize more clearly which processes have more influence within each impact category. It ensures that the results obtained from LCIA are presented in a consistent and meaningful way that can inform decision-making and help identify areas for improvement.

Weighting

Weighting is another step that is considered to be optional by the ISO 14040 standards. It is the final step in a LCA and involves assigning relative importance to the different impact categories identified in the LCIA phase. The purpose of weighting is to combine the normalized impact scores of each impact category into a single score that reflects the overall environmental performance of the product or process being assessed. Weighting is necessary since impact scores are dimensionless and cannot be directly compared without some form of normalization. Weighting produces one score which allows comparison of products or processes across an environmental spectrum on an equal playing field; however, due to being subject to subjective judgments that could be affected by different stakeholder preferences and values. Transparency and stakeholder engagement must be utilized for an equitable weighting process that can provide objective measurements of environmental performance.

Interpretation

Life cycle interpretation (LCI/ICA) is a systematic technique designed to identify, quantify, check, and evaluate information gathered through LCI or LCIA results. The intepretation phase includes 3 mandatory steps: the identification of issues that can potentially influence the final results of the study, the evaluation of the importance of these issues and finally the conclusions, recommendations and limitations of the study. While the results typically appear at the end of an LCA report, such techniques should also be implemented throughout each stage of study to identify issues or uncertainties and generate insights that lead to conclusions and recommendations for improvement of future research efforts. [7]

Identification

The purpose of the first element of the interpretation phase is to analyze the result of earlier phases of the LCA in order to determine the most environmentally important issues, i.e., those issues that have the potential to change the final results of the LCA.

-Goal and Scope definition: methodological choices and assumptions, such as the choice of the functional unit, the way of handling multifunctional processes and the boundary setting (if the case, also excluded processes)

-Inventory analysis: data for activities occurring in many parts of the product system, data for processes that contribute substantially to the environmental impact of the product system, data for elementary flows that contribute substantially to the overall score of an impact category.

-Impact assessment: characterization or normalization factors used in LCIA, the choice of the impact assessment itself, and of the impact categories to be considered. [8]

Evaluation

Evaluation consists of determining and specifying confidence in, and the reliability of, the results of the LCA or the LCI study, including the significant issues identified in the first element of the interpretation. At this step, it is crucial that each issue receives equal consideration based on its impact on the final conclusions. Furthermore, evaluation results must be presented so as to provide commissioners or any other interested parties a clear and understandable view of what was discovered during their study. The evaluation involves completeness check, sensitivity/uncertainty analysis and consistency check.

-Completeness check: for LCI and LCIA, determine the degree to which the available data is complete for the processes and impacts, which were identified as significant issues. If the missing data are important to satisfy the goal and scope of the LCA, the inventory and impact assessment must be revisited in order to fill the gaps. If this is not possible or very demanding, the goal and scope definition may have to be adjusted to accommodate the lack of completeness. If neither of the options is possible, this should be considered when formulating the limitations of the study. In case the missing information is found to be of little relevance, this has to be stated in the completeness check.

-Sensitivity and uncertainty analysis: sensitivity of the model is defined as the extent to which a variation of an input parameter or a choice leads to a variation of the model results. Sensitivity analysis is often conducted by calculating a sensitivity coefficient for each impact parameter. The procedure consists of perturbating each model parameter by an amount that can be considered aligned with the uncertainty of such parameter, or by the same percentage for all parameters (e.g., 10%). Next step is to calculate the coefficient using this formula : (∆IS/IS)/(∆ak/ak) , where ∆ak is the perturbation of the parameter k, ak is the original value of the parameter, ∆IS is the difference measured in the impact score value after perturbating the parameter k and ∆IS is the original value of the impact score. In a very general way, uncertainty may defined as the degree to which we may be off from the truth. The overall uncertainty of a model results can be disaggregated into four components: parameter uncertainty, model uncertainty, scenario uncertainty ( choices and preferences) and relevance uncertainty ( relevance and representativeness of the indicators used). The combination of sensitivity and uncertainty analysis helps identify focus points for improved inventory data collection or impact assessment.

-Consistency check: it is performed to investigate whether the assumptions, methods, and data, which have been applied in the study, are consistent with the goal and scope. If inconsistencies are identified, their influence on the result of the study is evaluated and considered to draw conclusions from the results.

Conclusions, recommendations and limitations

The conclusions should be drawn in an iterative way. Preliminary conclusions can be drawn based on the identification of significant issues and the evaluation of these for completeness, sensitivity and consistency. It is then to be checked whether the conclusions are in accordance with the requirements of the scope definition of the study. If so, they can be kept as final conclusions, otherwise they must be re-formulated and checked again. Specifying the limitations of an LCA study is also of vital importance, as it increases its credibility and provides with important information about its usability.

Applications of LCA in Project, Program and Portfolio Management

In order to better understand the role of LCA in Project, Program and Portfolio Management (PPPM), it is necessary to introduce the concept of Life Cycle Management (LCM), that can be defined as "a management concept applied in industrial and service sectors to improve products and services while enhancing the overall sustainability performance of a business and its value chains." (G.Sonnemann, M.Margini, chapter 2). [9] In other words, LCM means integrating a sustainability-oriented, holistic view on the life cycles of products, service activities and systems into managerial decision-making processes. LCA, as a tool of LCM, is being applied by several companies (especially in the last decade) to take better and more informed decisions, which is a fundamental aspect in PPPM. As an example, LCA can be particularly useful when starting a project, to decide which products, materials or procedures are better from an environmental point of view. In addition, Organisational LCA can be used to evaluate the environmental performance of suppliers and other partner organisations, to decide who to cooperate with during the implementation of a project. LCA is also very relevant in Portfolio Management, as it provides a basis for comparison between projects when deciding which ones to prioritize, as well as between different investment opportunities. To maximize the usefulness of LCA in decision-making processes, it should be used in combination with some or all the other LCM tools, which are Life Cycle Costing, Social LCA and Sustainable Product Design. [9] LCA, as a tool, follows more than one principle included in the "Guide To the Project Management Body of Knowledge, The standard for project management", publiced by the Project Management Insitute. These are: 1) " Be a diligent, respectful, and caring steward" , which refers, among other topics, to the respect and care towards the environment and communities. [10] 3) " Actively engage with stakeholders " . Regarding these principle, LCA can be a way to increase the interest of stakeholders into a product or a project that has a better environmental performance. [11] 12) " Enable change to achieve the envisioned future state" . LCA can be used to detect the need of change and to show why the change is needed. [12]

Strenghts and limitations

LCA's main strength lies in its comprehensive life cycle perspective and broad coverage of environmental issues, which enables the comparison of environmental impacts of product systems that comprise numerous processes and involve thousands of resource uses and emissions occurring in different locations and at different times. However, this comprehensiveness is also a limitation as it requires simplifications and generalizations in the modeling of product systems and environmental impacts, preventing LCA from calculating actual environmental impacts. Therefore, it is more accurate to say that LCA calculates impact potentials, considering uncertainties in mapping resource uses and emissions and in modeling their impacts over time and space.

Another strength of LCA, in comparative assessments, is that it follows the "best estimate" principle, ensuring unbiased comparisons through the same level of precaution applied throughout the impact assessment modeling. However, this principle's limitation is that LCA models are based on the average performance of processes and do not consider rare but catastrophic events such as marine oil spills or industrial accidents.

LCA cannot determine whether a product is fully sustainable in environmental terms; rather it provides insight into whether its environmental impacts have decreased relative to those of another product. Therefore, LCA is appropriate for answering certain inquiries but not others and its limitations must be kept in mind when interpreting its results. For example, LCA can tell us what is the most environmentally friendly option between a plastic bag or a paper bag to carry groceries back home from the supermarket. Although, it cannot tell us if a government should increase taxes on internal combustion vehicles to lower the emissions and therefore save money from lungs cancer treatments. That is because LCA cannot evaluate the social impact of increasing taxes with the positive environmental impact of lowering pollution. In this case, a Cost Benefit Analysis should be combined with Health Assessment Studies to better answer this question. [13]

Annotated Bibliography

The book "Life Cycle Assessment: Theory and Practice" is a comprehensive guide towards the world of LCA. It provides useful insights about the development of this practice throughout the years, as well as a detailed description of each step that has to be carried out to perform an LCA study. A lot of space is also given to the applications of LCA from government policies, to management to specific economy sectors such as buildings, food and energy systems. In addition, the book presents an example of a professional study carried out on different types of windows and a cookbook on how to write an LCA report.

The official website of the European Commission has a section dedicated to LCA, called the European Platform on LCA (EPLCA). It focuses on existing LCA project in Europe and especially on European guidelines and standards for LCA, mainly the International Life Cycle Data System (ILCD). ILCD standards integrate the ISO standards regarding the topic of LCA, because of the latter leaving a lot of space for subjective decisions and approaches. ILCD provides general guidelines on LCA as well as specific guidelines for each LCA phase.

"A Guide to the Project Management Body of Knowledge", publiced by the Project Management Institute (PMI), provides 12 Project Management (PM) principles to be a "good steward", as well as a wide range of models, methods and atrifacts that are useful in PM. LCA values ,and more generally LCM values, are widely shared by the PMI principles. That demonstrates how LCA could be a valuable method to be applied in PM practices.

References

- ↑ Sustainable Development and Other Solutions to Pollution and Global Change (2019), M.L. Brusseau, chapter 32, https://www.sciencedirect.com/science/article/pii/B978012814719100032X

- ↑ Life Cycle Assessment:Theory and Practice, chapter 3 (Michael Z. Hauschild, Ralph K. Rosenbaum, Stig Irving Olsen) https://link.springer.com/book/10.1007/978-3-319-56475-3

- ↑ M.L. Brusseau, Chapter 32 - Sustainable Development and Other Solutions to Pollution and Global Change,Editor(s): Mark L. Brusseau, Ian L. Pepper, Charles P. Gerba, Environmental and Pollution Science (Third Edition),Academic Press,2019,Pages 585-603,ISBN 9780128147191.https://www.sciencedirect.com/science/article/pii/B978012814719100032X

- ↑ Life Cycle Assessment:Theory and Practice, chapter 6 (Michael Z. Hauschild, Ralph K. Rosenbaum, Stig Irving Olsen) https://link.springer.com/book/10.1007/978-3-319-56475-3

- ↑ European commission website, https://eplca.jrc.ec.europa.eu/lifecycleassessment.html#:~:text=LCA%20is%20based%20on%204,impact%20assessment%2C%204)%20interpretation.

- ↑ National Institute for Public Health and the Environment Ministry of Health, Welfare and Sport; LCIA: the Recipe model; https://www.rivm.nl/en/life-cycle-assessment-lca/recipe"

- ↑ Patxi Hernandez, Xabat Oregi, Sonia Longo, Maurizio Cellura, Handbook of Energy Efficiency in Buildings, A Life Cycle Approach (2018), chapter 4; https://www.sciencedirect.com/book/9780128128176/handbook-of-energy-efficiency-in-building

- ↑ C. Cao, Advanced High Strength Natural Fibre Composites in Construction (2017), chapter 21.4.2.4; https://www.sciencedirect.com/book/9780081004111/advanced-high-strength-natural-fibre-composites-in-construction

- ↑ 9.0 9.1 Guido Sonnemann, Manuel Margini, et.al.; LCA Compendium- The Complete World of Life Cycle Assessment (2015) https://link.springer.com/book/10.1007/978-94-017-7221-1?page=2

- ↑ Project Management Institute Inc.; A Guide To the Project Management Body of Knowledge, The standard for project management, chapter 3.1 (2021) https://findit.dtu.dk/en/catalog/2702860479

- ↑ Project Management Institute Inc.; A Guide To the Project Management Body of Knowledge, The standard for project management, chapter 3.3 (2021) https://findit.dtu.dk/en/catalog/2702860479

- ↑ Project Management Institute Inc.; A Guide To the Project Management Body of Knowledge, The standard for project management, chapter 3.12 (2021) https://findit.dtu.dk/en/catalog/2702860479

- ↑ Life Cycle Assessment:Theory and Practice, chapter 2.3 (Michael Z. Hauschild, Ralph K. Rosenbaum, Stig Irving Olsen) https://link.springer.com/book/10.1007/978-3-319-56475-3