Minimizing Risk and Uncertainties in Construction Projects

Developed by Alberto Vilar Bustos

The difficulty of managing the individual flows in the construction process is mostly due to unpredictable conditions, scheduling pressures and the large amount of parts involved. This approach analyzes how uncertainties and risk are created and how they can be managed by the means of Lean Construction principles.

Contents |

Overview

One of the concepts that more effectiveness has demonstrated in the management of construction projects is the concept of Lean. The idea of Lean is to eliminate what does not add value from the perspective of the customer. In this analysis, the implications and consequences that the use of certain risk management methods have in Lean Construction are assessed.

In addition, it is essential to improve the projects management by identifying the risks, planning responses and coordinating the information flow and the resources. In order to give the widest range of solutions to this, three important methods are evaluated: the TFV-model (transformation, flow and value), the Last Planner System and the Location-Based Scheduling; concepts that are connected and used to mitigate the possible damage inflicted by unexpected situations.

In this approach, the correlation and development of these methods in the construction industry are also analysed.

Risks and uncertainties management with Lean thinking

Risk and uncertainty

From early phases, the overall project should be defined: scheduling, planning, cost, time and resources. But there is other information, a level of uncertainty, which needs to be recorded. Uncertainty can be defined as the difference between the information required to make a decision and the information available. There are two concepts attached to this[1]:

- Predictability, since the future is not known, and the past can be an invaluable guide.

- Complexity, since it is costly in terms of time, money and other resources.

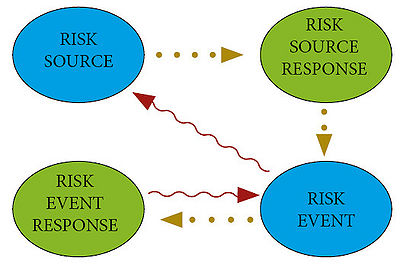

Risk is the probability of the occurrence of a risk event given its risk source. To define risk, two definitions should be considered:

- Risk source, as an underlying state of affairs

- Risk event, as something given due to the underlying state of affairs

When the needs of the owner and occupants of a building are not met, a risk event can be created from the design phase. In addition, modifying these needs during the project, or having a weak communication between the parts, can create the risk event.

In risk situations, there are parameters controlled by probability, known by the decision maker[2]. However, in uncertainty situations, parameters are uncertain and no information about probabilities is known. It is clear that construction management organizations do not have precise information, especially when making long-term planning. But it is possible to determine some parameters from experience or statistical data.

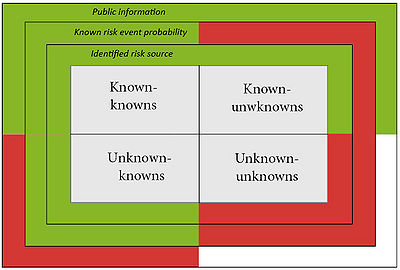

The uniqueness of a construction project leads to a high degree of uncertainty. Therefore, project managers must lean on risk management to identify, analyze, monitor and report risks. The project risk management uses four basic concepts to help identify the type of risk:

- Known-knowns: the risks have been identified and a probability can be assigned.

- Known-unknowns: the risks have been identified but a probability cannot be assigned to them.

- Unknown-knowns: the risks are the ones identified by someone who associates probability to them, but decides to hide that information.

- Unknown-unknowns: the risks have not been identified.

This being said, the purpose of risk management is to help eliminate the unknown-unknowns and decrease uncertainty by having all risks known-knowns. This way, the complexity will be minimized and also the predictability, to some extent.

Furthermore, it is necessary to control the risk source through the project life cycle, since the probability of risk events can be assessed when we receive and monitor the information. When the risk probability has passed the point of becoming a risk event, it can be removed from the risk register. This process requires the full implication and commitment of the project management team, because it is during this phase that awareness of possible unknown-unknowns events can grow.

In addition, uncertainties are the reason of possible cost overruns and delays. Many factors can be responsible of creating this uncertainties, such as the fluctuations in cost of materials, lack of resources, changes in design and specifications or financial problems. Therefore, a study of the possible cost overrun factors is required. But the most effective solution to this is to have a proper project planning, and Lean Construction is the ideal tool[3].

Lean Construction

Lean Construction can be defined as the adaptation of the principles of Lean Production to fit the needs of a construction project. The value is set by the client, and this value consists of the needs, wishes and demands. In order to maximize the values, it is necessary to deliver a product that fulfills the customer expectations at the proper time and quality. Lean Construction is able to achieve this by reducing the waste; this means, to eliminate all that is not relevant for the client’s values. Reducing waste is reducing waste of time, waste in not delivering what the customer wanted or waste in overproduction, among others.[4]

But to fulfill this waste reduction, the industry of construction has been developing different ideas or processes, continuously trying to find the best solution. In this approach three important tools to assess planning and risk management are analyzed:

- Transformation, Flow and Value.

- Last Planner System.

- Location-Based Scheduling.

Methods to minimize risks and uncertainties in construction projects

Transformation, Flow and Value

Lean Construction consists of several tools, which enable all parties to perform their tasks without compromising the resources. The TFV-model illustrates the different outlooks in project management. In order to discuss the parts of the TFV-model, it is necessary to differentiate the effectiveness, which is to do the right thing, and efficiency, which is to do it right.

This model consists of three concepts:

- Transformation: when the workers are told to do something, but not how to do it. This focuses on effectiveness, leading to low efficiency.

- Flow: the waste between processes is eliminated. It is important to know what to do, before knowing how to do it properly.

- Value: there is a focus on creating value for the client. Here is when the project management should be used.

Last Planner System

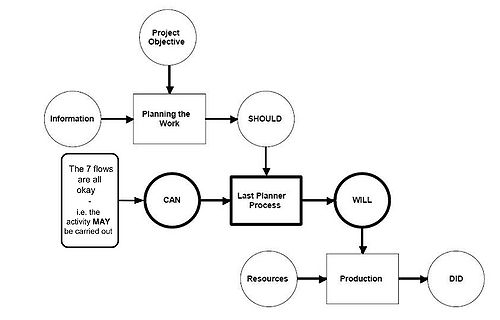

In order to facilitate the TFV-model, the LPS was developed for construction purposes. When managing a construction project traditionally there is a tendency to start the work, even if not all the resources required for the completion of the task are available. The Last Planner System addresses this problem with a break down structure of the schedule.

The method consists in dividing the construction process into three levels: phase, look-ahead and weekly work plan. This is done to provide an even workflow which enables the prediction of durability of the activities.

Firstly, a phase schedule is created, containing the overall construction project with the corresponding deadlines. Then, each representative is required to create a look-ahead schedule to clarify how the activities in the phase schedule should be done. Finally, weekly work plans are created during weekly meetings with the representatives. In these meetings, agreements are done about what to do on that week.

The LPS produces predictable workflow and rapid learning [5]. This creates the maximum value for the owner by eliminating waste caused by unpredictable workflow. Moreover, it enables contractors to reduce the delivery time of the project and creates commitments among project participants.

But even with the situation in which the schedule makes the weekly work plans efficient, there is another aspect to consider when the foremen are doing the planning on site: the weekly meetings are also oriented to commitment and trust among the parties[6]. This is achieved by letting the workers do the planning and adjust their own management to the overall project [7]. This way, an open and easy way to communicate is created.

In the Figure 3, the information flow and LPS process are shown. Regarding the concept of the 7 flows, which is part of this figure, it is used to represent the conditions that must be analyzed and met in order to perform an activity in a construction project:

- Prerequisite work: must be done

- Materials: must be ready

- Equipment: must be ready

- Personnel: must be qualified

- Right information: must be at hand

- Space: must be appropriate and safe

- External circumstances: should be clarified

Location-Based Scheduling

In response to the limitations of the Last Planner System, the Location-Based Scheduling method was created. This enables a more detailed schedule to be established in the design phase, where activities can be performed at the same time, reducing waste of time and resources.

This method aims to secure that under or overloading of resources does not occur. Research studies affirm that LBS is especially advantageous in terms of:

- Understanding the overall work plan and communication with sub-contractors and suppliers.

- Efficient resource flow.

- Evaluation and quality assurance of the executed work.

This follows the line of Lean philosophy and shares the advantages of the Last Planner System. It seems logical to assume that the efficient flow of resources in LBS will decrease the level of uncertainty, and therefore, decrease the variability of task durations. This being said, it can be stated that the LBS seems to be an adjunct to the LPS, rather than a replacement.

Locations are important in the construction industry since it is not a systematic repetitive process, but a series of physical locations in which tasks are variable and of different type and quatity[8]. The location is the container for data which relates to the project. The LBS is hierarchical so that a higher level location includes all the data of the lower level locations. Each of the locations have a different purpose and the highest level is used to optimize the construction sequence. Since the structures of such sections are independent of each other, it is possible to start them simultaneously. The middle levels are used to plan the production flows, and the lowest levels for planning the finishes. This allows the data to be collected at different levels. The location consists of the following data:

- Building objects: components such as elements and sub-systems, that should be included, not only in drawings, but also as a 3D object oriented construction model.

- Planned building component quantities: quantities measured from a 3D model. This way, variations in quantity which occur during construction should be able to be tracked.

- Building system assemblies: this includes the construction method, support components and building site planning.

- Material costs: cost related to the planned material quantities.

- Building system costs: costs of the components that must be included in each location. The labour costs should be calculated based on the actual resource available in the plan.

Limitations

Regarding the Last Planner System, there are a series of limitations. Firstly, the team should have some background training in the LPS and understand perfectly their roles in the process. Although it will create maximum value for the client, this requires training time and cost. In terms of scheduling, if a team member completes a task before it is schedule, the team needs to rethink the planning process. The next task could be done earlier, but it is not because the team member has not planned to do it. This can be defined as losses add up, and gains can never be recovered, and the team does not take advantage of the fast performance of the tasks. However, there can be a clause for which the team member must give notification with 24 hours in advance, if he anticipates the early completion of his task. This way, the team member in charge of the next task can adjust his plans as well.

Regarding the Location-Based Schedule, the incentive to implement this method seems obvious. But studies have concluded that the absence of a common coherent and standardized information system is a main challenge when implementing the system. The use of Information and Communication Technology (ICT) tools may solve this problem.

Bibliography

- ↑ Graham M. Winch - Managing Construction, 2010

- ↑ Uncertainty analysis in construction project’s appraisal phase, Ustinovičius, D. Migilinskas, J. Tamošaitienė, E.K. Zavadskas, n.d.

- ↑ Cost overrun factors and Project cost risk assessment in Construction industry - Savita Sharma and Pradeep K. Goyal, 2014

- ↑ Jakob Lemming, Lecture 3: "Lean Construction" from 42286 Planning and Management in Construction, 2015

- ↑ Recommended practices for the application of Lean Construction methods to building new australian LNG capacity, Engineers Australia, Western Australia Division, 2012

- ↑ Building Information Modelling (BIM) in Design Detailing with focus on Interior Wall Systems, Janni Tjell, 2010

- ↑ Rolf Simonsen, Lecture 4: "Last Planner System" from 42286 Planning and Management in Construction, 2015

- ↑ Location-Based Management of Construction Projects: Part of a new typology for project scheduling methodologies, Russel Kenley and Olli Seppänen, 2009

Annotated articles

This article is related to other relevant pages in the APPPM wiki: