Modularity and Black-Boxing

Developed by Ana Latorre Duque

Abstract

Complexity is an obstacle ever present in any business. Managing complex systems is therefore a core competency to successfully run any business. This article is part from the course 42433 – Advanced Engineering Project, Program and Portfolio Management E15 at DTU. This is an individual assignment and the reason why this topic has been selected is because of the personal interest of the author on it. To allow success in a company, project or program it is important to learn how to transform complex systems (meaning processes, concepts, architectures, etc.), in small black boxes that can be easily handled. It means to decouple processes and actions to face many small tasks instead of a really big one, what can be hard to manage or even picture it in the managers’ mind. The structure of this article is defined by the following sections:

- Modularity in different areas: Within the field of engineering modularity can be used in many different areas, this article will focus on three main areas of interest: product architecture, portfolio management and project management, and how they build each other.

- Application: Here it will be addressed how to take to due modularity and two techniques will be described (black-boxing, DSMand MFD)

- Limitations: This final section will discuss the limitations of this concept applied to the areas described in the article

Contents |

Big Idea

Modularity refers to how components relate. It consist on coupling and decoupling, connect and disconnect the different parts and features of a product. Nowadays simplifying complexity is not just about reducing it while we are, at the same time amplifying variety, because customers always want it customized and, of course, faster, cheaper and better. This is where the challenge begins. Below this paragraph there is a viral diagram that express how it cannot be pursued it the three areas or it will fail.

The term modularity is used in a wide range of fields within management. It means that systems can be decomposed into subsystems that can be matched in many different configurations. Those subsystems are components, and they have the ability to interact, connect or exchange variety of resources. To make this possible it needs to be defined a standard interface. Imagine modules as puzzle pieces and the interface the puzzle panel.

In Industrial design, modularity refers to an engineering technique that builds larger systems by combining smaller subsystems. In manufacturing, modularity refers to the use of exchangeable parts or options in the fabrication of an object.

To improve the business value and the chances of success in an organization it should grow in three areas. It a company is better in product leadership and goes the first to the market it will be the one who set the price and have in this way a strong position with possible competitors. To shape your product or service to fulfill customer’s needs is called customer intimacy. The last one is operational excellence, which means that the way the company is doing it is efficient, minimizing waste, being the first in time to market and managing resources allowing lower costs increasing the revenue.

Here modules are defined within these three areas, then there are some groups of modules that can be optimized based in the strategic intention of group in these three areas defining the boundaries and connections between modules and areas.

Modularity in different fields

Modularity in product architecture

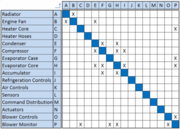

Every product architecture is based in modularity. A product is intentionally decomposed into a system of functionally coherent building blocks. Each module provides a unique function within the product architecture. Modularity is the key for managing complexity and the more complexity there is in a product the more useful will be the use of modules or black-boxes. Each module have its own strategy within the company strategy such us fulfill customer’s need or reducing manufacturing costs. According to businessdictionary.com, product family is defined as Group of products derived from a common product platform. These goods or services use similar or same production processes, have similar physical characteristics, and may share customer segments, distribution channels, pricing methods, promotional campaigns, and other elements of the marketing mix. Products comprising a family are usually priced and discounted as a package. Several product families make up a product portfolio. Also called product group or product line. Product family architectures are crucial in the development of new products within a family and this architecture is based in a shared platform that allows the creation and exchange of some of the modules. A good modularization allows a wide range of products within the same product family, which means customization and optimization. This variety will describe how the customer’s needs are fulfill in different areas and niches. Optimization in means of reducing the cost of manufacturing and time to market. By improving processes and sharing a common language. Strategic modularization is based in a shared platform and the definition on the modules of the product. Those modules can be defined by function or assembly. This is a strategy since it allows a better approach to portfolio management within a company. If the modules are well defined and they share resources and physical interfaces it becomes much easier to make them relate to create a wide range of variety without increasing cost (processes and materials) and time to market. To decide the future architecture of a product it can be helpful to think on the module drives described by Erixon 1998. The modular function development (MFD) is a good approach for the identification of those modules having the starting point in the customer requirements and the module drivers. A way to decompose a product into standard designs, modules or platforms is the “Design Structure Matrix” which can be seen in the picture.

The Design Structure Matrix (DSM) is a simple tool to perform both the analysis and the management of complex systems. It enables the user to model, visualize, and analyze the dependencies among the entities of any system and derive suggestions for the improvement or synthesis of a system. Such a system can be for example a product architecture or an engineering design process; also e.g. the organization of an enterprise or a market can take shape as a complex system and often merit a closer look into their structure.

Modularity in portfolio management

The modularization is also applied in a superior level, at portfolio management. This modularization allows the creation of product families in a portfolio by simplifying processes and saving materials, which also means optimization in means of money, time to release the product and customization. A company’s portfolio is classified in families and subfamilies decoupling systems and processes. This aids the production and help to manage easier projects within a company.

Modularity in Project management

This kind of modularity is also called strategic modularity. Regarding modularity of projects it allows the internal design strategy by shorting the time to learn and making the process more efficient that could be basis for a competitive advantage.

Application

Summing up the previous section, modularization is a strategic behavior that allows managing complex systems and process by decoupling them. But, how can we do it? There are some techniques that can be applied to simplify the way we manage processes and systems, here three will be described: Black boxing, the design structure matrix and the modular function development.

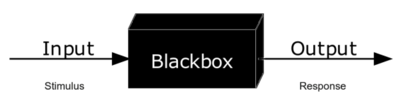

Blackboxing

The term black-box engineering is derived from the fact that the component in question appears as a black box, what means that to see the overall system it is not necessary to have it all. It consist in making groups of the process that are similar in time, shape or resources and put it in a black box and show how they relates. If it is necessary a black box can be open and you can look what there is inside, maybe many systems or more black boxes. Therefore the term black box and the action black boxing can be applied to any field. In this case this article will use it in relation to business management.

In this strategy the inquiry is focused upon a thing that has no immediately apparent characteristics and therefore has only factors for consideration held within itself hidden from immediate observation, and this is an intended feature. To release the weight of too much information and focus in the things that maters in every moment. The observer is assumed to be ignorant in the first instance as the majority of the available data is been keeping in an inner situation inside some black box away from facile investigations. These black boxes can contain anything within the system such as processes, parts, algorithms, relations between other boxes or even more boxes. In the following figure it can be seeing how black boxing relates boxes and helps to visually manage the information to be aware of what it is needed and not to be disturbed by anything else.

Once we face a black box we can decide if it is not relevant for the entire system or if we need to open and take a look inside broadening our boundaries and our scope. This needs to be defined in advance since not every department should be managing the same information since they don’t share the same point of view in the project.

Design Strategy Matrix (DSM)

This Design Structure Matrix is also known as:

- The Dependency Structure Matrix

- The Problem Solving Matrix

- Design Precedence Matrix

As a tool for system analysis, DSM provides a compact and clear representation of a complex system and a capture method for the interactions/interdependencies/ interfaces between system elements (i.e. sub-systems and modules). As a management tool, DSM most commonly applied in project management, and it provides a project representation that allows for feedback and cyclic task dependencies. This is extremely important since most engineering applications exhibit such a cyclic property. As such, this representation often results in an improved and more realistic execution schedule for the corresponding design activities. There are several tools as templates and software that are designed to aid the manager and the team to develop the best strategy for the business. For example Antares DSM is a software tool that allow the manipulation of all types of DSMs and make possible the creation of new models. This software have also the possibility to execute and simulate functions to optimize the DSM projects.

Below it can be watch a tutorial video about that easily explain matrixes and how to work with them and learn to read them.

Modular Function deployment

Modular function deployment is a structured approach for modularization of products based on Erixon 1998 and module drivers. This approach consist of 5 tools linked together and the objective is to identify the different modules of a given product. Steps to follow: 1* Identification of the customers’ requirements described a QFD-matrix. 2* Identify functions and corresponding technical solutions. 3* Analyze technical solutions regarding their reasons for being modules. The output here is module candidates. 4* Analyze modules according to their interfaces, lead times, cost, etc. 5* Made specifications for each module.

Limitations

By taking a brief and very visual look into the section called modularity in different fields of this article, it is clear that the first subsection we explored (modularity in product architecture) was much deeper explained than the rest (modularity in portfolio management and modularity in project management) that are clearly much more shorter, this is because this article has been completed through the application of black boxing, being one section into another and building each other. Therefore modularity in product architecture was explained in a wide basis and then the relation with the upper fields within a company or organization. The limitations of this practice is the practice as such, since by symplifying it is possible that we miss something in the meanwhile

Annotated bibliography

- http://www.dsmweb.org/ - This is a web I strongly recommend if the reader is interested in how the DSM works. This web have a large collection of tools such as professional software. There is an important network of researchers in this area.

- Modular management (YouTube channel): https://www.youtube.com/channel/UCwHU0MFRozXGpcV31PKxDjw , This YouTube channel is much recommended to get to know the principles of modular management in a simple basis. It is easy to follow and understand, moreover there are some examples that engage the audience.

References

- Project Management Case Study: http://vanderweil.com/resources/2010Hallahan.pdf.pdf

- Definition of Black Box: https://en.wikipedia.org/wiki/Black_box

- Industrial use of DSM (inspiration): http://www.dsmweb.org/en/understand-dsm/industrial-use-of-dsm/team-composition.html

- Modular Product Architecture definition: https://www.youtube.com/watch?v=bf2f8Ezr6-Y

- Simplifying complexity: https://www.youtube.com/watch?v=nSmGb3lE3Mw

- Edwin D. Marion and Eric J. Riddleberger (1991). Modular project management: http://findit.dtu.dk/en/catalog/15627515 / http://ieeexplore.ieee.org.proxy.findit.dtu.dk/stamp/stamp.jsp?tp=&arnumber=6772421&tag=1

- Oehmen, J. et al 2015

- Developing productc families based on architecture, Ulf Harlou