Safety risk management in construction sites

Building construction sites are some of the most dangerous places to work in where unfortunately roughly 60.000 people lose their life every year around the globe[1] due to the high number of falling objects, heavy machineries, mishandling of equipment and tools, moving trucks and so on. Nevertheless, a huge responsibility is placed upon the project manager to ensure that all the potential risks workers might encounter are eliminated and, if not possible, they must be minimized.

Before digging into the concepts, it is relevant to understand what a risk is[2]; according to Macquarie Dictionary, risk is the chance of an adverse event depending on the circumstances and its impact can be measured as the likelihood of a specific unwanted event and its unwanted consequences or loss[3] and it can be identified mathematically as follows  .

.

There are multiple types of risks in a typical construction site that could affect the safety of the workers, such as: vibrations, noises, respiratory hazards, handling of heavy materials, electrocutions and many more. These risks may lead to different types of immediate consequences, from a small injury to even death; however, some complications caused by the constant exposure to one of the risks mentioned above, such as noises, could manifest in months or even years, known as professional illnesses.

Given the importance of such topic, there are a few steps explained in this article that can be followed to guarantee the safety of everybody working in construction sites. The points are the following: identification, assessment, treatment/prevention and inspections/maintenance. It must be said that, regardless of how thorough and accurate the safety risk management may be, some incidents can not be avoided due multiple factors, for instance their unpredictability or also, in certain circumstances, the low level of attention or carelessness of the workers themselves. This process is meant to find the sources of the risks and eliminate or minimize them, but it can not fully solve the issue.

Contents |

Overview of safety risks

A construction site can be a rather chaotic place with plenty of risks that can pose a threat to the health and safety of workers. Some of the most common risks workers can face in a construction site are[4] :

- Falls from different heights that can involve workers or objects which can cause small injuries, permanent physical disabilities or even death in the worst cases. A few important points to take into consideration are the slipperiness of the floor where workers are operating, the type of shoes they are wearing and also the protection elements around them that could prevent them from falling, for instance the horizontal bars on a scaffolding

- Vibrations, typically caused by construction tools workers have to handle and vehicles. This type of risk does not immediately evolve into an accident, however it can cause professional illnesses in the long run depending on the level of exposure

- Noises, similarly to vibrations, they can be caused by tools and machineries. If not minimized, it can cause issues to the hearing system and in the worst cases, even permanent hearing loss

- Respiratory, this risk depends usually on: the environment in which workers are operating, such as in not well-ventilated closed rooms or the sewer system, the type of products they are using which could be toxic if inhaled, for example spray paints, and also the type of material they are operating on that could pose a threat to their respiratory system, like asbestos

- Handling of heavy materials, this could generate issues to muscles and especially bones such as the spine depending on the methods used to handle the materials and the number of times a worker needs to lift an object

- Electrocution, which can occur when utilizing certain electric tools and can generate fires or even explosions.

Relation between safety risk management and project, program and portfolio management

The main aim of the safety risk management is to identify all the potential risks in a construction site, assess them to finally find a way to eliminate them or minimize their impact on the workers. This topic strictly correlates to project, program and portfolio management since it is a process that should and must be taken into consideration across all levels whenever workers are involved in the construction phase.

Projects, programs and portfolios are three correlated topics[5]:

- Projects could be non dependant on other projects or included in the umbrella of programs

- Programs deliver benefits and is usually a conglomeration of projects

- Portfolios may contain both projects and programs that could potentially not even be related to one another.

When it comes to project management, safety risk management is about identifying safety risks regarding the project, more specifically the construction phase, for instance potential workplace risks, equipment defects and so on, to then implement strategies to eliminate/mitigate the risks which could translate into informing or training the workers, properly maintaining the equipment and other forms of intervention.

Regarding program management, safety risk management focusses once again on identifying potential safety risks, but this time in the context of multiple projects within a program, to then adopt strategies to minimize the risks.

Finally, with regards to portfolio management, safety risk management concerns on identifying safety risks across multiple programs and projects within a portfolio and eradicate or mitigate the hazards.

Essentially, safety risk management is a fundamental part of project, program and portfolio management because it is critical to protect and preserve the lives of whoever is involved in the construction of the projects by adopting strategies or following the regulation.

Management of safety risks

In this section, the whole process regarding the management of the risks potentially present in a construction site will be explained. This is a process meant to identify and try to eliminate or mitigate as much as possible all the risks that might harm the workers.

Here are the fundamental steps to follow.

Identification

This is a critical part of the process since it lays the foundation for the further steps of risk management. It is a rather complicated topic since it is done before the work begins and therefore it is based on the ability of the project manager to figure out where the risks may arise and in what circumstances[6].

The project manager or whoever is responsible for the safety of the workers should gather as much information as possible regarding similar projects and the accidents and risks that were identified[7]. This is a great way to use past databases that can help spot the sources of risk in today’s construction sites.

Furthermore, communication is vital in many areas, including risk identification; it is suggested to talk to other engineers, project managers or even the workers to see if the can contribute to the process of identifying the risks also relying on their experience in past works[7]. Since many accidents are caused by equipment or tools, it could be useful to verify the instructions of everything the workers will have to use in order to assess the hazards they might encounter[7].

Overall, this firs phase of the safety risk management process relies on the knowledge and experience of the project manager who has to identify the risks or third party individuals who might be involved like the manufacturers of tools or the workers themselves.

Assessment

This is the step in which the risks identified in the previous phase are evaluated and prioritized based on their probability of occurring and the negative effect they might have on the labor force employed in the construction site[6].

Although there are multiple ways to complete this part, two main groups can be defined to assess the risks:

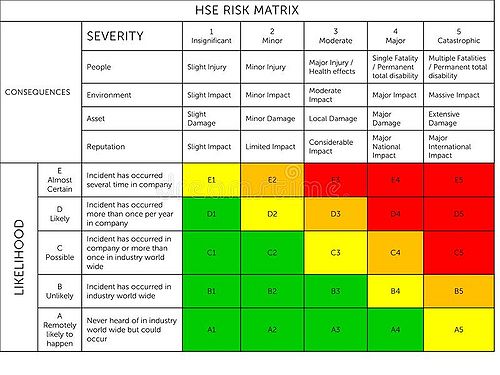

- Qualitative, it is a simple way which consists in evaluating how likely it is that a risk can cause an accident and its potential impact through interviews, brainstorming and checklists[8]; afterwards, the risks are placed in a matrix called risk assessment matrix that illustrates all the risks ranked based on their severity and probability (low, serious/medium and high)[7] as it can be seen in figure 1.

- Quantitative, this is a more complex method that aims at estimating how often a risk can impact the workers and its gravity[8]. There are different ways to assess risks by using method, such as the tree analysis or the Monte Carlo simulation. It is worth mentioning that nowadays around the world there are companies that offer software that can simplify the lives of project managers, such as CerTus that not only after a few inputs can easily generate accurate risk management models, but also automatically fill out mandatory paperwork regarding health and safety of workers that must be submitted to the local municipality before beginning the construction[9].

Treatment/prevention

As already mentioned, after having identified and evaluated the risks, it is vital to eliminate them in order to make the environment as safe as possible. However, quite often many sources of risks can not be eradicated, therefore they must be minimized through different ways.

One of the most effective ways to treat risks is by adopting PPE personal protective equipment[7], this is probably one of the most effective steps in guaranteeing safety in a construction site. Workers are in general obligated to wear PPE, however there are times when they need to wear a specific type of equipment only when it is necessary, such as protective goggles and masks when spray painting or when slicing wood or materials that release harmful particles which might end up in the eyes or be inhaled. Nevertheless, when working on strategies to protect workers, collective protective strategies should always be prioritized over individual ones, such as PPE, since they tend to be passive, meaning that there is no human action required.

Here are a few collective precautions that should be taken into account:

- Limit the number of workers who could be exposed to a risk

- Limit the chemical products workers might be exposed to

- Make sure the workplace is as safe as possible

- Try to minimize the amount of times workers are exposed to risks

- Adopt evacuation plans and measures in case of an emergency

- Install safety signs in places where a risk is not completely eliminated.

An aspect that is even more important than treating the risks is prevention, which focusses on preventing a risk from causing an accident in the first place.

Something fundamental when it comes to prevention is to inform the workers about the risks they might encounter in the construction site and prepare/train them on how to behave and tackle them; this can be done through courses and workshops supervised by the employer[7].

Furthermore, all workers should be frequently checked by a professional doctor to make sure they are in good health conditions to work efficiently and, if for instance they are not due to long exposure to noises, they should be treated properly and rest until it is necessary.

Inspections/Maintenance

A fundamental aspect of this whole process is related to inspecting and conducting maintenance on all the PPEs and other protective equipment or measures taken because if they malfunction or fail to fulfill their purpose, they could put some workers at risk. If some PPEs are defective or broken, they should immediately be fixed and, if it is not possible, they should be replaced with new ones by the employer.

An important role in relation to the inspection is also played by the workers themselves since they should also be trained to ensure they can identify a malfunctioning PPE to then report it to the manager straight away who should subsequently substitute it with a new one.

Each PPE has specific instructions specified by the manufacturer that should be taken into account by the safety manager, especially the section about the maintenance of the equipment, such as: how to identify failures, the average service life of the products, and so on. It is the safety manager’s responsibility to ensure that the measures put in place are effective and continue to do so during the construction process by inspecting and monitoring the risks constantly[6].

Limits of the safety risk management process

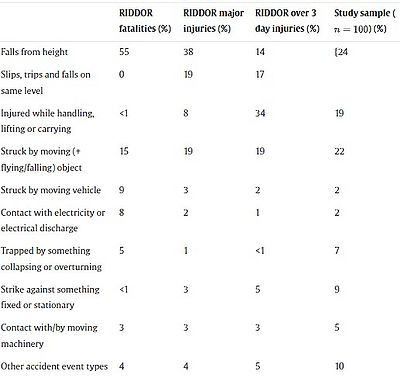

Construction sites are dangerous workplaces with numerous sources of risk, therefore it is vital to find them and eliminate or at least minimize them. The process described is quite effective and in theory it should eliminate or mitigate all the risks present in a construction site. However, nothing is flawless or perfect and there are always elements that are overlooked or neglected that end up causing accidents, sometime lethal, as it is illustrated in the figure 2 below.

This process requires filling out a lot of paperwork, depending on the law and documents required by each country, and therefore it used to be very slow and time consuming; nevertheless, thanks to new software such as CerTus[9] and many more, it has gotten faster and more efficient to complete. It must be said though that it requires an experienced and knowledgeable manager who can successfully identify and assess all the risks to find a way to reduce them, but unfortunately some people argue that it is not easy to find these types of experts and that the educational system should put more emphasis on the topic of safety risk management in order to have more professional engineers able to conduct a thorough analysis of risks[11].

In general, the process meets its goal of eliminating and minimizing the residual risks; the reason why there are still accidents and deaths occurring on a daily basis is not entirely because of the process itself, but rather because of unidentified risks, design flaws, lack of training and precaution when working[10], which is why workers always need to be trained and taught to be on constant alert and how to behave when facing a risk; preventing is better than curing.

Overall, as much as we try to predict the risks in the design phase or attempt to find them in construction sites, there will always be unknows, elements that we are not aware of.

Annotated bibliography

1) Matej Mihić (2020). "Classification of construction hazards for a universal hazard identification methodology". Research gate. (Ch. 1.1, 1.2, 1.3, 1.4 and 3) https://www.researchgate.net/publication/339107995_Classification_of_construction_hazards_for_a_universal_hazard_identification_methodology

This study focusses on breaking down the different types of hazards that can be encountered in a construction site by workers and assessing them. There are a lot of different classifications of safety risks in construction sites and this study provides a different approach compared to the one used in the wiki article which is worth noting.

2) Benjamin O. ALLI (2008). "FUNDAMENTAL PRINCIPLES OF OCCUPATIONAL HEALTH AND SAFETY". INTERNATIONAL LABOUR OFFICE • GENEVA. https://www.ilo.org/wcmsp5/groups/public/---dgreports/---dcomm/---publ/documents/publication/wcms_093550.pdf

This is a rather comprehensive document provided by ILO (International Labour Office) which clearly describes all the different aspects mentioned in the article but in a deeper and more extensive version. The document can provide further understanding of multiple topics such as: risks, regulations, prevention strategies and so on.

3) Dietmar Elsler EU-OSHA (2011). "Innovative solutions to safety and health risks in the construction, healthcare and HORECA sectors". European Agency for Safety and Health at Work. file:///C:/Users/pc/Downloads/innovative-solutions-OSH-risks.pdf

This complete document is quite similar to the ILO's but it is related to European countries since it was published by the European Agency for Safary and Health at Work. It specifically goes deep into the topic of solutions to adopt in construction sites to reduce the risks and prevention with a few checklists that might be useful when assessing the risks in a real scenario.

4) ILO (1992). "Safety and health in construction". International Labour Office, Geneva. https://www.ilo.org/wcmsp5/groups/public/---ed_protect/---protrav/---safework/documents/normativeinstrument/wcms_107826.pdf

This document was published by ILO (International Labour Office) and is an interesting and detailed read since it dives deep into all the different types of work environments and risks in a construction site and breaks them down to provide a clear explanation about what they are and aspects to take into consideration when working in certain conditions.

References

- ↑ Helen Lingard (2013). “Occupational health and safety in the construction industry”. Research Gate. https://www.researchgate.net/publication/263552916_Occupational_health_and_safety_in_the_construction_industry#:~:text=According%20to%20statistics%2C%20the%20death,worldwide%20every%20year%20%5B5%5D%20.

- ↑ Josef Oehmen, Christian Thuesen (2023). "42433: Uncertainty in Project, Program and Portfolio Management". Risk, uncertainty, ignorance.

- ↑ Anthony Mills (2001). “A systematic approach to risk management for construction”. Emerald Insight. https://www.emerald.com/insight/content/doi/10.1108/02630800110412615/full/html?casa_token=jWz-aT1 efAAAAAA:lmJT0vBRzG_Bq9cGElDnvDB5tVEFMtXJgCZHgv3brjA2U24WqKFpqg4GM3JlMkTS3E-s5hs8zD1wgcbXzeOrQ0J3wf1_q70KR6agbCkPaowsRJPNQw

- ↑ European Agency for Safety and Health at Work (2014). “Construction safety risks and prevention”. OSHwiki. https://oshwiki.osha.europa.eu/en/themes/construction-safety-risks-and-prevention

- ↑ Josef Oehmen (2023). “42433: Introduction to Program Management”. Fundamentals of program management

- ↑ 6.0 6.1 6.2 Martin Schieg (2006). “RISK MANAGEMENT IN CONSTRUCTION PROJECT MANAGEMENT”. Tandfonline. https://www.tandfonline.com/doi/epdf/10.1080/16111699.2006.9636126?needAccess=true&role=button

- ↑ 7.0 7.1 7.2 7.3 7.4 7.5 7.6 Devdatt P Purohit*, Dr.N A Siddiqui, Abhishek Nandan & Dr.Bikarama P Yadav (2018). “Hazard Identification and Risk Assessment in Construction Industry”. Research India Publications. https://www.ripublication.com/ijaer18/ijaerv13n10_56.pdf

- ↑ 8.0 8.1 Nerija Banaitiene (2012). “Risk Management: Current Issues and Challenges”. IntechOpen. https://books.google.dk/books?hl=en&lr=&id=6d2dDwAAQBAJ&oi=fnd&pg=PA429&dq=construction+risk+management&ots=8SsN0IEQPW&sig=Sn8RJL5zsLH0QXnN1OlntlPami8&redir_esc=y#v=onepage&q=construction%20risk%20management&f=false

- ↑ 9.0 9.1 CerTus. “Piani di Sicurezza. Acca software. https://www.acca.it/software-piani-sicurezza

- ↑ 10.0 10.1 R.A. Haslam a, S.A. Hide a, A.G.F. Gibb b, D.E. Gyi a, T. Pavitt b, S. Atkinson a, A.R. Duff c (2005). “Contributing factors in construction accidents”. Sciencedirect. https://www.sciencedirect.com/science/article/pii/S0003687005000335

- ↑ Akintola S Akintoye and Malcolm J MacLeod (1996). “Risk analysis and management in Construction”. Sciencedirect. https://www.sciencedirect.com/science/article/pii/S026378639600035X