Training within industry

This page has been written by Frederik Daniel Olesen S164361

Contents |

Abstract

Training within industry (TWI) is a programme/method which was developed under World War II. It was the result of a need to quickly mobilize and train a workforce to provide value to industry and thereby society. The method works with four Supervisory Skill Development Modules to ease delivery and ensure results. With any project or program a manager has a variety of needs and TWI recognizes this as well and has developed a list of five needs which encapsulates the need for anyone whose work depend on results from other people – from the first line managers to the executive management controlling a wide portfolio. TWI worked with the multiplier principle, which in its original state certified over 1.7 million supervisors and trainers throughout the United States in its brief five-year existence. The method also includes a number of specific tools from which the strategy of the method can be implemented as intended. Despite the historic origins of the method, TWI is still relevant today and is applied in a variety of industries at different levels for various purposes. The continuing application of lean practices has also increased the relevancy of the method and as this article will show clear ties can be drawn between TWI and Toyota Production System (TPS) and thereby lean. The use of standardised ways of working within TWI is connected to lean project management and parallels are drawn to current standards.

Motivation

Why should you even be bothered to read this wiki article about Training within industry (TWI) as project, program or portfolio manager? The TWI programme serves as an impressive example of the power of running a successful programme. The standard Project, programme and portfolio management – Context and concepts : DS/ISO 21500:2021 seems to exemplify this process.[1] Specifically the strategy implementation of the standard could be projected to the TWI programme. The TWI programme started with the US government recognising both the threats and opportunities present at the time (more on that in the Origin and early application section).[2] From there a strategy was formed aiming to become a leading force within production to enable the Allied forces. Based on this, specific requirements were formed together with a business case. This included the quick mobilising of an unexperienced workforce to ramp-up production quickly. From this the TWI programme was conceived and the benefits, which will be shown in this wiki article, were many and significant. TWI essentially helped realising the strategy and arguably helped the Allied forces win World War II.

Today it is hard to not encounter lean practices when studying any company out there. What makes TWI somewhat special in this regard is the fact that for many consider TWI as an inspiration for the Toyota Production System (TPS).[3] As will be described in the next section TWI started due to an economy that was under pressure while demand for industries were high. After the World War II Japan found themselves in a similar situation from which TPS was born which still today remains highly relevant.

Origin and early application

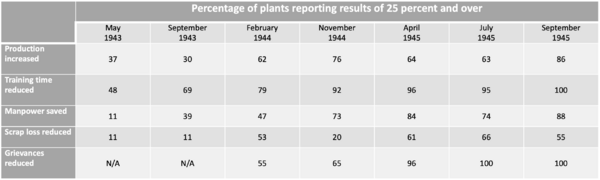

The results was very significant. From having a hard time responding to increasing demand, companies who applied the method of TWI were able to increase production, reduce training, save manpower, reduce scrap and reduce grievances. [4] Table shows the results of participating companies from May 1943 to September 1945.

A popular example often described in relation to TWI is that of lens grinding.[5] This was considered a complex craft which took about 5 years to master. By the end of 1945 the time to master this craft had been reduced to six weeks by breaking the process into smaller parts based on the concept of Job Instructions Training.

The big idea

The Training Within Industry (TWI) method was developed by defining Four Supervisory Skill Development Modules. [2] The first three of these are what is referred to as the The J Training Programmes and these will be described in detail later. The fourth module is Programme Development which essentially recognized that any organization has unique problems and their employees must be trained to deal with these unique problems. In fact, all of these principles of TWI are so universal that they can be used beyond the initial industrial applications for which they were originally designed for.

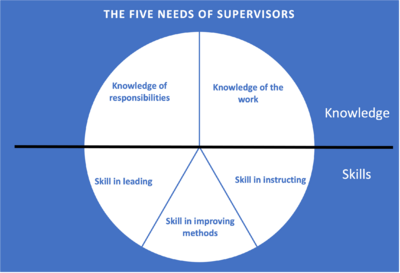

The Five Needs of a Supervisor

Part of Training Within Industry (TWI) is a philosophy which was used to underline the reasoning of applying the method of TWI.[5] This philosophy is known as The Five Needs of a Supervisor and states that every supervisor has these needs:[2]

- Knowledge of the Work

- Knowledge of Responsibility

- Skill in Instructing

- Skill in Improving Methods

- Skill in Leading

The combination of both knowledge and skills must work together in harmony to extract the full potential.

Knowledge of both the work and responsibility is the responsibility of the plant or company to enable the work of supervisors.[2] This knowledge includes equipment, products, and the skills required to manufacture them, as well as company policies, agreements, schedules and more. The TWI method enables the last three needs of the supervisor by training the supervisors of companies through the so-called J programmes.[5] Three different J programmes were designed for each of the three remaining needs of a supervisor.

Knowledge of the work is like the name suggests a need for supervisors to know the materials, tools, processes, equipment, operations that are all related to the production of the product such that daily operations can be successfully carried out.[5] The knowledge of responsibility is essential for managers to carry out their work both efficiently and effectively. Policies, agreements, rules, regulations, schedules, interdepartmental relationships, etc. are all crucial buildings blocks for this.[5]

Skill in instructing is all about transforming your new workforce to a valuable part of the company as efficiently as possible such that they can provide value as soon as possible.[5] This has with it a lot of benefits and include but is not limited to faster ramp-up, less scrap, less rework, less rejects, fewer accidents, and less equipment damage.

Skill in improving methods is all about achieving products or services of high quality in greater volumes.[5] This is done by learning supervisors to study processes so they can eliminate, combine, rearrange, and simplify. Basically removing waste as it is known from traditional lean practices.

Skill in leading is all about people. Managing people is as big a part of a successful operation as managing the technical aspects.[5] Since the direct results of supervisors work is dependent of the people they work with, it is essential that they understand individuals so they can deliver the expected results.

Common for all the skills are that they can be taught individually through the J training programmes, but mastering the skills are only obtained through applying the principles through practice and experience in a real world setting.

From theory to practical application

From the philosophy of the five needs of a supervisor the J training programmes were developed to educate supervisors. [6]

The J Training Programmes

Each of the J Training Programmes address one essential skill area for effective supervision. The programmes were all taught in five sessions of two hours each.[2] Each of the programmes follow a four-step method for which a number of recommended questions/steps were developed. The following sections will present the main steps and for the elaborating questions/steps the reader is referred to the annotated bibliography.

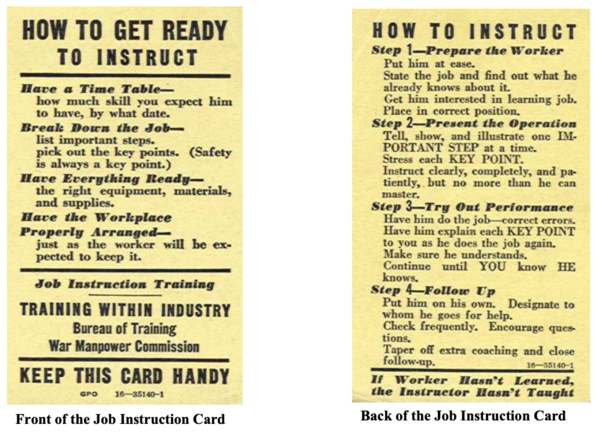

Job Instruction Training (JIT)

The Job Instruction Training (JIT) programme is focused on the supervisor's need for skill in instructing. The main emphasis behind this programme is that "If the learner hasn’t learned, the teacher hasn’t taught". The developed guidelines are relatively simple and can be divided into two elements.[2] Firstly the necessary preparations are defined in three points and are:

- Decide what the learner must be taught in order to do the job efficiently, safely, economically and intelligently.

- Have the right tools, equipment, supplies and material ready.

- Have the work place properly arranged, just as the worker will be expected to keep it.

After and only after a four step process can then be carried out. These four steps are often distributed as instruction cards to ease the process. The first step here is the preparation of the learner and includes:

- Put the learner at ease.

- Find out what he already knows about the job.

- Get him interested and desirous of learning the job.

The next step then presents the necessary knowledge related to the operations which are being taught. This step follows this procedure:

- Tell, Show, Illustrate, and Question in order to put over the new knowledge and operations.

- Instruct slowly, clearly, completely and patiently, one point at a time.

- Check, question and repeat.

- Make sure the learner really learns.

The third step is where the employee is tested out in the so-called performance try-out step. This step follows these points:

- Test learner by having him perform the job.

- Ask questions beginning with why, how, who, when, or where.

- Observe performance, correct errors, and repeat instructions if necessary.

- Continue until you know he knows.

The fourth and final step is the follow-up which makes sure the training has been successful and does so by:

- Put him “on his own.”

- Check frequently to be sure he follows instructions.

- Taper off extra supervision and close follow-up until he is qualified to work with normal supervision.

What is significant to this programme is the focus on following this very specific procedure such that only value is added ensuring the efficiency of the teaching and effective learning of skills and knowledge.[6]

Job Relations Training (JRT)

So the main purpose behind this programme is the fact that a supervisor success is highly dependant on the relations he/she has with his employees and so the working theory is that poor relationships causes poor results and good relations lead to good results. This programme is being applied by emphasising some key foundation points which are:[2]

- Let each worker know how he is getting along.

- Give credit when due.

- Tell people in advance about changes that will affect them.

- Make best use of each person’s ability

Another key part of this programme is accepting that problems will arise and so a clear method was developed to tackle these:

- Get the facts.

- Weigh and decide.

- Take action.

- Check results.

Job Methods Training (JMT)

Like the two other J programmes this programme also follows a structured approach. The idea here is that no special technical knowledge is required since this programme aims at taking a practical approach. For this a simple four step process was developed:[2]

- Break down the job

- Question every detail

- Develop the new method

- Apply the new method

This programmes relies on the fact that in most operations there are obvious improvements to be made if you follow a systematic procedure like the one just presented. By breaking the current operation into smaller elements uncovering what is actually value-adding and what is not.

Programme Development

The final module called programme development was created to support the learnings created by the J training programmes.[5] A key principle behind the method is the multiplier principle, which certified over 1.7 million supervisors and trainers throughout the United States in the period of World War II.[2] Programme development recognized that companies would have to set up training within the company itself such that to solve their company’s own production problems using the learnings of the J training programmes. To support this effort a four step process was designed containing:

- Spot a production problem

- Develop a specific plan

- Get plan into action

- Check results

Current applications

Despite the lost interest in Training within Industry (TWI) after World War II in the USA[2], the method is still being applied in various industries around the world today. There can be found many examples of the application TWI for various purposes. The benefits include: [7]

- Establishing standardized work with the purpose of improvement.

- Capturing knowledge from experienced employees.

- Continuous improvement efforts.

- Focus on a safe work environment.

- Higher employee retention.

- Easier and faster training process.

Limitation and relation to lean practices

Like mentioned in the beginning of this wiki article, clear ties can be drawn between Training within Industry (TWI) and Toyota Production System (TPS). TPS and lean as a concept is clearly used in all industries from tools on the production floor to forming corporate strategies inevitably influencing projects, programmes and portfolios. From the TWI programme several key elements can be projected towards current lean practices.[2] Learn by doing was the foundation from how TWI was taught. Another example is the reliance on both supervisor development and that of the workers - essentially what can be described as coaching kata in Toyota Production System (TPS).[6] Continuous improvement Kaizen along with 5 whys and 5W 1H (Why, What, Where, When, Who, and How) to identify and remove waste can also clearly be tracked back to TWI.[6]

Evidently, TWI can be argued to be the predecessor to TPS and lean. But at the same time TWI is far from what lean has become today, which is so much more than the five needs of a supervisor and J-training programmes. Nonetheless as a project manager or in a similar role, the subject of lean project management has become more or less standard practices. The working principles from TWI and thereby lean have now been standardised in project management in the way of lean project management.[8]

Lean project management is all about carrying the attitude of lean into project management and an entire wiki article could easily be written on the subject. The basic ideas however include waste reduction, specifically Muda(wasted effort), Muri(overcommitment) and Mura(inconsistency).[8] With this approach you should be able to reduce completion times, improve efficiency and add more value. The main objective is the concept of using standardised tools and here these can be used as examples:

- DMAIC (Define, measure, analyze, improve & control)

- Kanban

- Plan, Do, Review

And this bring the article back to the motivation paragraph. Because since lean project management is all about using standardised methods, then the application of standards such as the standard Project, programme and portfolio management – Context and concepts : DS/ISO 21500:2021 is all within the spirits of TWI.

Annotated bibliography

Singh, Rajinder, and Noela Ballerio. “TWI (Training Within Industry).” Wcom (World Class Operations Management), Springer International Publishing, 2016, pp. 227–44, doi:10.1007/978-3-319-30105-1_20.

This is a chapter of a book focusing on the application of TWI in todays settings. It takes on the perspective of operations management with the goal of optimizing an organization It provides a tangible way of applying the principles of TWI. In addition it also brings a number of interesting perspectives J-training programs and elaborates on key elements to successfully implement TWI.

Huntzinger, Jim. The Roots of Lean Training Within Industry: The Origin of Japanese Management and Kaizen. 2014.

This reference is a comprehensive look into the origin of TWI. It starts by defining the history including its roots The Four Horsemen and Charles R. Allen and even discuss TWI's relevancy before World War II. Focus is then put on the content of the courses within TWI before looking at the programme's application in Japan after World War II.

Graupp, P., and R.J. Wrona. The TWI Workbook: Essential Skills for Supervisors, Second Edition. Taylor & Francis, 2017. https://books.google.dk/books?id=ZJHwCgAAQBAJ.

This book is a complete guide to the TWI method. It starts by describing relevancy to todays application, especially at Toyota. It then takes on a thorough walkthrough on all the TWI courses.

Soltero, Conrad, and Patrice Boutier. 2012. The 7 Kata : Toyota Kata, TWI, and Lean Training. CRC Press,

This book, besides giving an interesting insight to most of the lean tools available also provides a good understanding of why you should consider TWI when you are pursuing the values of lean. It takes on a very pragmatic approach for any company to use and improve organizational synergies and improve its lean practices.

Erne, R. (2022). Lean Project Management - How to Apply Lean Thinking to Project Management. Lean Project Management - How To Apply Lean Thinking To Project Management. Springer Fachmedien Wiesbaden GmbH.

This book provides an interesting look at common problems project managers can face and how the principles of lean can be used to solve some of these problems. First a theoretical description of classic project management is provided with typical tasks and methods along with the limitations of these. Examples are then used to show how lean project management can be beneficial in a variety of situations.

References

- ↑ Project, programme and portfolio management – Context and concepts. (2021).

- ↑ 2.00 2.01 2.02 2.03 2.04 2.05 2.06 2.07 2.08 2.09 2.10 2.11 2.12 The Roots of Lean Training Within Industry: The Origin of Japanese Management and Kaizen. (2014).

- ↑ 3.0 3.1 Graupp, P., & Wrona, R. J. (2017). The twi workbook: Essential skills for supervisors: Second edition. Twi Workbook: Essential Skills for Supervisors: Second Edition (pp. 1–312). Taylor and Francis. https://doi.org/10.1201/b19661

- ↑ 4.0 4.1 4.2 War Production Board, Bureau of Training, Training Within Industry Service, September 1945, The Training Within Industry Report: 1940-1945, (Washington D.C.: U.S. Government Printing Office), page 92.

- ↑ 5.0 5.1 5.2 5.3 5.4 5.5 5.6 5.7 5.8 Ballerio, N., & Singh, R. (2016). TWI (Training Within Industry). Wcom (World Class Operations Management), 227–244. https://doi.org/10.1007/978-3-319-30105-1_20

- ↑ 6.0 6.1 6.2 6.3 Soltero, C., & Boutier, P. (2012). The 7 kata : Toyota kata, TWI, and lean training (pp. xxv, 165 s.). CRC Press,

- ↑ Ruona, W. E. A. (2001). The Foundational Impact of the Training within Industry Project on the Human Resource Development Profession. Advances in Developing Human Resources, 3(2), 119–126. https://doi.org/10.1177/15234220122238274

- ↑ 8.0 8.1 Erne, R. (2022). Lean Project Management - How to Apply Lean Thinking to Project Management. Lean Project Management - How To Apply Lean Thinking To Project Management. Springer Fachmedien Wiesbaden GmbH.