Using the bowtie method to evaluate the risks in a construction project

Developed by Filip Møller Knudsen Knudsen

Contents |

Abstract

The primary goal of risk management in construction is to give a systematic approach to identify and respond to potential risks which may arise during the lifespan of a project.

The risk exposure for construction projects arise from the very beginning of the development idea, to the handover and following operation of the site. During all phases, there are many aspects where risk is involved. A few of these aspects include, project material e.g. architectural drawings, communication platforms, safety of craftsman, weather conditions, force-majeure, finances and stakeholder engagement. Thus, it is important to start a risk management process before actually starting the construction project, in order to create a systemic, and analytically sound way of managing risks throughout its lifespan.

This article will focus on a method to assess potential risks within construction, specifically using the Bowtie method as a reference point. When having read the article the reader will have a deeper insight into the Bowtie method in theory as well as have insight as how to apply the Bowtie method in real case scenarios.

Introduction

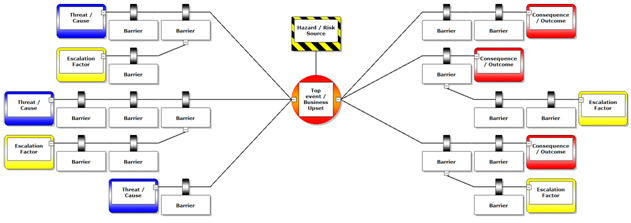

In short, the Bowtie method visualizes the hazardous events that are present during a project, it gives an overview of multiple plausible scenarios that can occur during a project. The bowtie method was inspired be three different methods, The fault tree, the event tree and casual factors charting. The combination of these three risk assessment methods give an extensive overview of what the risks are, how to prevent them, what to do it the risk becomes “alive” and what the following consequences are.

The precise origin for when the Bowtie method was developed is not completely clear. One of the first large corporations that used the Bowtie method was the Royal Dutch / Shell Group. They started using this method because of the explosion leading to 167 deaths on the Piper Alpha platform in 1988. The motivation for Shell was to ensure that the necessary risk controls are consistently in place in all operations worldwide.

The Bowtie method is often used in the gas and oil industry, however it has gained a lot of support from other companies and industries because the method keeps an easily read overview of risk management practices.

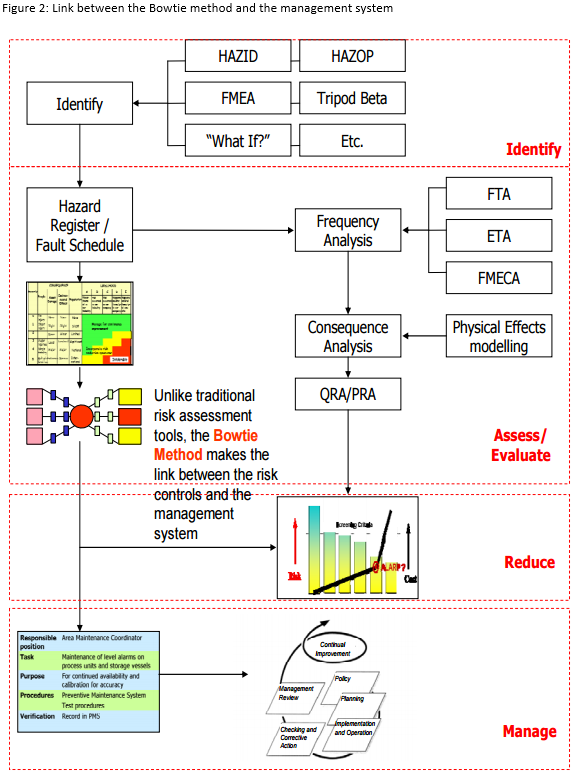

The Bowtie method a qualitative hazard assessment tool and unlike traditional assessment tools because it has a direct link between the risk controls and the management system.

When analyzing and demonstrating the relationships in risky scenarios the Bowtie method is a good tool to use. By communicating the risks and providing a clear roadmap the bowtie method is a risk evaluation method that gives a visual understanding of plausible accidents that exist concerning a specific hazard. It identifies control measures that can be used by a company to control the outcome of the hazard.

Unlike some evaluation methods the Bowtie method is more detailed by identifying ways these control measures fail. These are known as escalation factors. The escalation factors also have possible control measures. The method also shows the mitigation measures and consequences for the hazard in question.

When using a Bowtie diagram, it should also be considered that management systems are to be integrated. By doing this it is possible to visualize the activities that keep a control working and who is responsible for this. Before using the Bowtie method an initial investigation of failures and unwanted events must be carried out, this can be done by using FMEA (Failure mode and effects analysis).

The key activities in the Bowtie model is:

1: Identify major hazards and top event

2: Identify the threats

3: Identify the consequences

4: Identify the prevention and recovery controls

5: Identify escalation factors and controls

“Some important questions to consider when developing a Bowtie diagram include the below questions:

- What are the hazards and their causes?

- What occurs when control is lost?

- What are the potential consequences?

- How can the hazard be avoided?

- How can the organization recover should the event occur?

- How can the likelihood and/or severity be limited?

- How might controls fail or effectiveness be reduced?

- How are control failures prevented?” [2]

Description of the Bowtie method

[3]Identify major hazards and top events

In all types of projects, it is essential to identify all potential hazards that can have a significant effect for the project. It is important to have a pro-active approach when identifying the hazards. This includes all the hazards that could occur later during the project and not only at the time where the assessment is made.

When finding the hazard a preliminary hazard analysis is done. The analysis includes brainstorming, checklists and other identification methods. A particular hazard which is analysed though the Bowtie method can give a high level of detail and gives a comprehensive understanding of the hazard. Not all types of hazards should be used in this method, it is therefore important to setup appropriate criteria for identifying the major hazards. The best way of identifying these hazards is done by using the risk matrix. By using a risk matrix your only pick the hazards that have the biggest impact or are most likely to occur during a project. This could be e.g. working at high places (roofs, scaffolding, ladders, mobile lifts) because a consequence could be serious injure or even fatality.

When having found a hazard it must be documented even if there already are control measures in place. This shows the management team who is responsible for this particular hazard and what actions have been taken to deal with the risk.

When defining the top event, the major hazard has to be defined first. At this point, when the control is lost, the damage has not yet occurred but has the potential to become a disaster if nothing is done to control it. In regard to the example above the top event could be the workers falling of the scaffolding.

Identify the threat

When identifying a threat, the Bowtie method uses a different approach from other risk assessment tools. Instead of just focusing on what and when a hazard can go wrong, the Bowtie method gives a detailed assessment of understanding the causes for the hazard to happen and why the hazard happens.

The identification process is similar to when identifying a hazard. When listing all the threats it should be a comprehensive list relating to all the potential threats, but at the same taking no regard to the probability of them occurring. An example could be unsafe scaffolding.

Identify the consequences

The consequences are subsequent to the top event. There is typically more than one consequence to a top event. The consequences should be worst case scenarios that are listed comprehensively. Usually the consequences in a bowtie analysis are most likely assets that are endangered or people are harmed.

“Consequences are events not the actual loss or damage”[4]

The outcome of the consequence is the loss or damage. E.g. an injury that a person suffers from a fall. The consequence here is the fall itself. The outcome of the consequence is the injury. It is important to not only look at the consequence/ damage in the project itself, but also the significance of the reputational damage that can affect the industry.

Identify the prevention and recovery controls

When knowing the threats and consequences the mitigating process can begin. At this point it is crucial to consider the controls on both sides of the hazard. Typically, there are different types of prevention and recovery controls, human behavior, mechanical equipment, technology etc. It is important to know that the prevention controls only act against potential threats, as the recovery controls only mitigate the potential consequences after the top event has happened.

Prevention and recovery controls can be sequential or parallel controls. Sequential controls work in the way that if one control fails the next in line will step in. Parallel controls function in an either/or relationship. Because the Bowtie diagram is a visually easily understandable tool it can seem that it only deals with sequential controls however this is not the case.

When these mitigation controls have been identified the basic understanding of how risk is managed is known. To have a more extended knowledge in prevention and recovery controls it is possible to expand the structure in to more detail and identifying the weaknesses of the controls, however this is not always a good idea due to the increase of complexity when viewing the diagram.

Escalation factors and escalation factor controls

The reason for using escalation factors is for investigating how the prevention or recovery control may be degraded. Escalation factors reduce the effectiveness of controls and lead to an increased level of risk. It increases the probability of the top event, however it cannot directly cause it. This is because the connected prevention or recovery control will be degraded or fail.

When describing the escalation factors, only the real weaknesses in the control framework should be looked upon and how to manage the weakness.

The Bowties final step is how the escalation factors are managed by escalation factor controls. Basically they have the same role as the prevention and recovery controls, but they are used for the escalation factors.

Case study

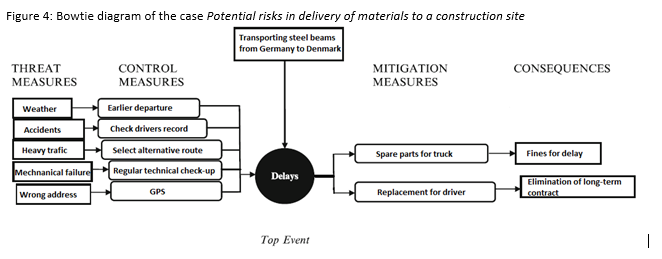

This case is about the potential risks in delivery of materials to a construction site.

The case setup is: A contractor has an agreement with a supplier that he needs 200 steel beams to build the skeleton of a new arena and the transportation time is 2 days. The event in this case is the possibility of delays.

The case only looks at the delivery, we assume that the production of the steel beams has been done correctly and on time. First of all, we start with identifying the hazard that is involved. This is done by brainstorming among other risk identification methods. In this case the major hazard is a delay in the transportation of the steel beams from Germany to Denmark. This is assumed to be a major delay because if the steel beams are not delivered on time the entire construction project can be delayed, resulting in fines and possibly bad publicity.

After knowing the hazard, the threats can now be found. Here the question is “what can happen so a delay can occur?”.

The causes or threats that can have an effect on the delivery date can be weather conditions, mechanical failure, personal failure (accidents) etc. If any of these threats occur it will lead to a delay for the expected delivery time. (the top event).

Now the prevention controls are identified by asking “what can be done to prevent the threats from happening?”

The prevention controls in this case could be, due to the weather start the journey earlier, notice of traffic conditions, regular control of the truck, check driver record (accidents).

The recovery controls/mitigation measures can be spare parts for the truck and have an extra driver as replacement. The consequence in this case can be fines for delay, elimination of long-term transport agreement. When all this is put I a Bowtie diagram it looks like:

Discussion

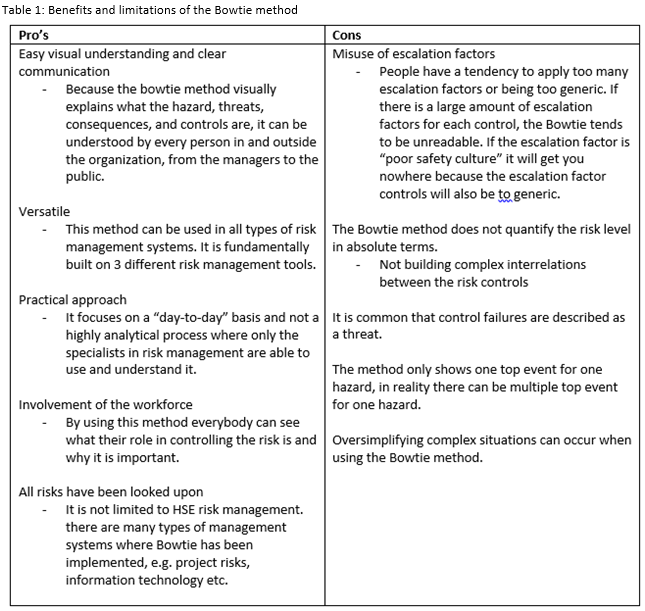

In general, the Bowtie analysis method gives a good overview of what hazards there are regarding a project. It gives a detailed overview of the control measures that are applied to prevent or contain the top event from escalating. However, there are some flaws when dealing with large management systems. The diagram can quickly grow and by doing so the benefit of the “simple” overview is lost. It is therefore critical that when constructing the analysis and diagram, the people that are doing so have an extensive experience in the field they work in, by doing so only relevant data is used.

As described earlier the Bowtie method has a direct link between the risk controls and the management system, this gives the management team a clear understanding of who is responsible for what risk control. By having this chain of command everybody knows their specific role if a hazard should occur. However, this also means that each person involved in the risk controls always have to have new courses to improve their knowledge and the techniques they use to overcome the hazard.

A weakness of the Bowtie method is that the project or system that it is applied in should be fairly simple. If the complexity of the project increases it will not be adequate on its own. Here several other risk assessment and hazard analyses tools may be needed as well.

Annotated bibliography

Georgi Popov, Bruce K. Lyon, Bruce Hollcroft Risk Assessment A practical guide to assessing operational risks

This book provides the fundamentals of risk assessment.

Nolberto Munier Risk Management for Engineering projects

Chapter 4 gives an introduction to the identification process of risks in a project. The book gives a brief introduction and a short case study of the Bowtie method.

Luca Podofillini, Bruno Sudret, Bozidar Stojadinovic, Enrico Zio, Wolfgang Kröger Safety and Reliability of Complex Engineered Systems

The book gives an introduction to the Bowtie method

http://www.cgerisk.com/ (CGE Risk Management Solutions B.V.)

The web page gives a description of the Bowtie method. They have developed specific software that uses the Bowtie method as a risk assessment tool.

References

- ↑ http://www.risktec.co.uk/media/43525/bow-tie%20lessons%20learned%20-%20aiche.pdf

- ↑ Risk Assessment, A practical guide to assessing operational risks by Georgi Popov, Bruce K. Lyon & Bruce Hollcroft page 184.

- ↑ http://sitesafety.ca/risk-management-solutions/the-bowtie-method/

- ↑ http://www.caa.co.uk/Safety-initiatives-and-resources/Working-with-industry/Bowtie/Bowtie-elements/Consequences/