Integrated Design Process (IDP)

m |

|||

| Line 5: | Line 5: | ||

IDP done successfully identifies slippage and problems before the production phase and saves the project cost, enhances quality, optimizes operations in production and after and facilitates for development of sustainability in contraction. | IDP done successfully identifies slippage and problems before the production phase and saves the project cost, enhances quality, optimizes operations in production and after and facilitates for development of sustainability in contraction. | ||

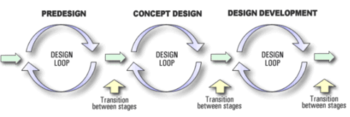

| − | The constant communication and design control ensures less mistakes and better solution of complex problems that appears. The design process consists of several stages that the relevant teams decides together, therefor it can be illustrated with several loops before very milestone. | + | [[File:Integrated_Design_Process.png|thumb|350px|'''Figure 1''': . Illustration of Integrated Design Process <ref name="Integrated Design Process"> Lean Enterprise Institute,http://task23.iea-shc.org/integrated-design-process, accessed: 08.02.18</ref>]] The constant communication and design control ensures less mistakes and better solution of complex problems that appears. The design process consists of several stages that the relevant teams decides together, therefor it can be illustrated with several loops before very milestone. |

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| − | |||

<references/> | <references/> | ||

Revision as of 14:52, 15 February 2018

The Integrated Design Process (IDP) is a high performance, holistic, method that mostly appear in conjunction with a construction project and refers to a process where the design of the construction is done in close collaboration and with consideration for the other stakeholders. It is a process where the different design teams (for example: Architect, Structural engineeers, Building Services engineeers, etc.) work closely to make sure the all of the aspects of the design is adapted to make the design as good as possible. For this reason, the term “Whole building” is often seen in the context of IDP. All of the subjects focus on making the construction with each other and the user in mind.[1][2]

Compared to the traditional design process, where one team wins the offer and then outsource the other technical tasks to different team after a design is made, the teams interact on the same authority level, discuss issues and opportunities to best meet the client’s requirements. The goal is to be more efficient and ensure that the quality is not jeopardized in one or more decisions, and that the different designs is integrated for its overall purpose.[3]

IDP done successfully identifies slippage and problems before the production phase and saves the project cost, enhances quality, optimizes operations in production and after and facilitates for development of sustainability in contraction.

- ↑ [1] Public Service and Procurement Canada (2018). Integrated Design Process.

- ↑ [2] Project Management Institute, (2008).The Standard for Management - Second Edition. Publisher: Project Management Institute. Page 71

- ↑ [3] Moe, Kiel, (2008). Integrated Design in Contemporary Architecture. Publisher: Princeton Architectural Press.

- ↑ Lean Enterprise Institute,http://task23.iea-shc.org/integrated-design-process, accessed: 08.02.18