Fishbone diagram analysis

(→Fishbone diagram combined with components of safety management framework in developing of solutions.) |

(→Fishbone diagram combined with components of safety management framework in developing of solutions.) |

||

| Line 80: | Line 80: | ||

In the cause category of equipment project managers could consider adopting the redundancy approach as a solution to causes that relate to this category. It is a backup system or else a duplication system. This means that if one component fails, another takes in. It is certainly a proactive approach to problems and the main tool to reduce risk. Redundancy could be applied to causes that contribute most to the identified problem. | In the cause category of equipment project managers could consider adopting the redundancy approach as a solution to causes that relate to this category. It is a backup system or else a duplication system. This means that if one component fails, another takes in. It is certainly a proactive approach to problems and the main tool to reduce risk. Redundancy could be applied to causes that contribute most to the identified problem. | ||

| + | |||

As a solution to problems related to people category, project managers could borrow the leadership, operational control and learning concepts. | As a solution to problems related to people category, project managers could borrow the leadership, operational control and learning concepts. | ||

The leadership and commitment management can be implemented in the brainstorming process. In order to improve it, there could be a coordinator of the session who makes sure every group member is heard and respected and sets a time limit to it. | The leadership and commitment management can be implemented in the brainstorming process. In order to improve it, there could be a coordinator of the session who makes sure every group member is heard and respected and sets a time limit to it. | ||

| + | |||

The stage of operational control includes procedures of training and educating the personnel related to the project. The learning stage includes the “learning form past mistakes” approach and can be related to the statistical analysis mentioned above. | The stage of operational control includes procedures of training and educating the personnel related to the project. The learning stage includes the “learning form past mistakes” approach and can be related to the statistical analysis mentioned above. | ||

Revision as of 13:35, 19 February 2021

Developed by Maria Konstantina Papaioannou

Contents |

Abstract

Risk project management is a broad and complex field. It is well established that every project at every stage carries risk. Possible risks for a running or finished project are countless and may vary from anticipated to unexpected. In addition, their result ranges from minor inconvenience to disrupt of the project. Thus, identifying possible risks is a key challenge for every project. Once identified and listed those risks can be categorized using qualitative risk analysis. This article introduces the Ishikawa fishbone diagram as a method to analyze numerous reasons why a project may fail. The diagram provides a visualization that simplifies the identification of risks and categorizes them. It heavily relies on the idea that minor problems matter and can lead to causes that affect badly the existing project. It is commonly used by safety and reliability engineers to detect faults in constructions. Firstly, this article gives a historical overview of the diagram. It analyzes its basic components, provides detailed guidance to its building, and briefly presents its implementation on the Apollo 13 case. Additionally, the article displays the technique’s benefits and refers to its disadvantages. Finally, it reflects critically on its limitations and makes recommendations on how to maximize the diagram’s utility.

Description of Ishikawa fishbone diagram

Historical overview

Japanese organizational theorist Kaoru Ishikawa(石川 馨)was born in 1915 in Tokyo, Japan and he is considered key figure in the development of quality initiatives. (book Guide to Quality Control. Tokyo: Asian Productivity Organization) During the year 1968, while working as a full-time professor at the Faculty of Engineering at the University of Tokyo, Ishikawa studied the concept of quality and introduced the seven quality management tools for projects’ improvement in his book Guide to Quality Control. In the book Ishikawa explains thoroughly the concept and the utility of each of the following tools: Ishikawa diagram, the histogram, the Pareto chart, the check sheet, the control chart, the flowchart, and the scatter diagram. The book includes instructions on building and the reading the quality control techniques mentioned above. The Ishikawa diagram became increasingly popular since it is a simple visual technique for problem solving and is used until today in modern management projects. Ishikawa diagrams were popularized in the 1960s by Kaoru Ishikawa,[3] who pioneered quality management processes in the Kawasaki shipyards, and in the process became one of the founding fathers of modern management.

Building the diagram

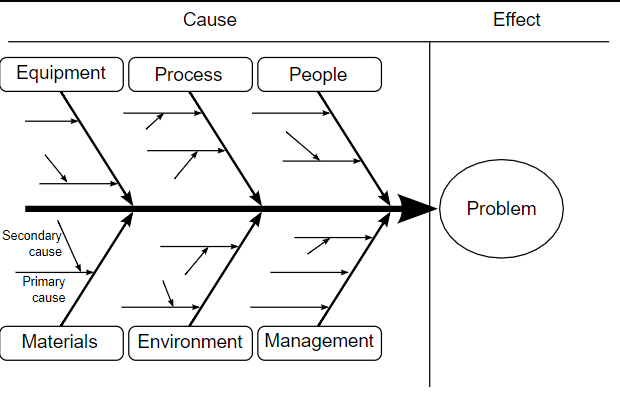

Ishikawa fishbone diagram is a technique that helps users visualize and sort numerous reasons why a project may fail. It combines brainstorming with a concept map. It can be implemented in various kinds of projects such as manufacturing, marketing and so forth. The Ishikawa diagram is also referred to as cause-and effect (CE) diagram because of its function. Most commonly it is referred to as the fishbone because of its unique shape. A completed fishbone diagram includes a central "spine" and several branches very similar to a fish skeleton. The head of the fish represents the problem of the project and the causes are connected with its spine that is the x-axis of the diagram.

According to ref, to effectively build the fishbone diagram a group must carry out the steps that are presented below:

Step 1: Group members should brainstorm and agree on potential effects/near misses that might or had already threatened the success of a project. The problem statement will be placed later in the right side of the diagram and will be represented by the head of the fish.

Step 2: Each member should agree on the major categories of causes that lead to the problem. Though it is up to the team to select the causes’ categories, usually depending on the nature of the project, the most common categories used are: equipment, process, people, materials, environment, management.

Step 3: Identification of causes. The causes are organized under the category they are related with and are represented by lines that lean on the x axis.

Step 4: Identification of sub-causes. Sub-causes are branching off the cause branches. Those are represented by lines parallel to the spine of the fish. By continuous searching of the causes of the problem, the group generates deeper levels of them. It is noteworthy that one cause might match with more than one category. Through those line segments, representation can be simple, but it can become more complex by completing with qualitative and quantitative appreciations and risks that characterize each cause.

Step 5: Analyzing the diagram and developing of solutions to correct the causes and improve the process or product. Once the process is completed there will be numerous identified root causes -most likely too many to solve at once. Thus, at this point the team will need to select the root causes they wish to initially solve and target effort and resources on them.

The fishbone diagram implemented on the Apollo 13 incident

The key of the technique is that it is very helpful in scoping the problems of a particular project and getting on top of them by identifying the causes. In order to thoroughly understand the diagram’s utility, a specific example with a problem statement and its causes is presented below. Let us use as the example the Apollo 13 mission. The initial goal of this project was the 7th land on the moon. The launch of the spacecraft during the Apollo 13 was a success, but during the flight the first oxygen tank exploded and after a while the second one followed. After that, both the crew in the mission control room and the astronauts turned their full focus and effort on the safe return of the astronauts in Earth. The problem statement in this mission is the explosion of the oxygen tank. Potential causes of this defect are mainly related to three categories: People category: Starting at the building of the oxygen tank, one potential cause of the explosion on behalf of the engineers could the negligence or lack of training while testing the tank. Equipment category and materials: The causes under those categories are technical. One additional cause could be related to the environment category in the sense that space travel will never be routine. Even if the entire country focused immense resources and effort to the project of landing on the moon, the project is still considered a major leap of faith.

Benefits

The fishbone diagram has a long history of over 50 years of use. It is one of the original techniques developed to help problem solvers understand the causes of a problem. The benefits of the technique are presented below. The fishbone diagram is a comprehensive and simple visualization of a complex reality. It pictures all the factors that lead to the defect of a project in a structured way. In project management simple and minimal models are often very popular. It provides an overview of both primary and underlying causes. Interestingly, in some cases the most apparent cause turns out to be minor and causes that were considered unimportant may lead to the defect. This diagram helps the project group emphasize on that and gives the opportunity to identify the root causes which will lead to a long-lasting resolution. Fishbone diagram has nearly unlimited application. It can be implemented in research, manufacturing, marketing, office operations and so forth. Because it gives a clear and holistic overview of the project’s potential or existing problems it can have both a reactive and a proactive action. Therefore, by understanding and analyzing the contributing factors of a system failure or a near miss the project team can avoid it or improve it. Additionally, the diagram may be utilized by both data oriented and non-analytic companies. The diagram encourages group participation. The brainstorming process is mainly popular for its democratic nature. Group members have the opportunity to be creative, snowball their way through the problems and give a unique perspective to the identification of the causes and sub-causes.

Limitations

Some of the disadvantages of the fishbone diagram could be related to the nature of brainstorming. Brainstorming in order to come up with causes and sub-causes is an early stage of the diagram’s building. It can turn out to be an unstructured or even chaotic process. Due to this, during brainstorming, some colleagues might be outvoiced and the process might be very time consuming. This means that a great amount of time can be dedicated to this early stage of the building of diagram and not to the developing of the solutions. In addition to that, brainstorming could be considered as subjective because it is often based on opinions rather than on fact evidence. The Ishikawa fishbone diagram might also fail to capture the interrelationships of multiple factors that contribute to the problem statement. Some categories of the diagram can be connected: for instance, the materials could be connected to the people category in the suppliers’ sector.

Recommendations

Fishbone diagram combined with data analytics in data driven companies.

It can be combined with analytics and statistics. By using internal or external data and assigning the data visualizing the results to qualified co-workers, project managers would be in position to respond to identified weird patterns or trends. For example, in the marketing field data analysis can have huge impact on a project’s development as it detects customers’ behaviour patterns and preferences. Additionally, collecting data of previous similar projects and perform statistical analysis to them answers the question which problem is more likely to occur based on previous experience. This way, the group can focus mostly on fixing those problems. Since the diagram is related to the uncertainty component of Project Program and Portofolio management, if combined with a risk or safety management model it could provide even better insight of the problem and its solutions.

Fishbone diagram combined with risk management models in order to rank the problems.

Once the effects are identified by the team, as mentioned above, the fishbone diagram offers no guidance as to what solve first. In this case, the effects could be organized in two categories: existing problems or potential problems. Both of these categories can be ranked according to the severity of the impact that they had/will have on the project and their probability of happening. In the ranking process the risk matrix could be extremely useful. After that, groups should start with dealing with the problems whose consequences would be catastrophical and reaching to problems that have residual and torelable risk. This way the fishbone diagram can be implemented multiple times to all of those.

Fishbone diagram combined with components of safety management framework in developing of solutions.

Safety is a legitimate management objective in every project. The safety management framework consists of four key concepts:

a. Top commitment management/Leadership.

b. Redundancy.

c. Operational control.

d. Learning.

In the cause category of equipment project managers could consider adopting the redundancy approach as a solution to causes that relate to this category. It is a backup system or else a duplication system. This means that if one component fails, another takes in. It is certainly a proactive approach to problems and the main tool to reduce risk. Redundancy could be applied to causes that contribute most to the identified problem.

As a solution to problems related to people category, project managers could borrow the leadership, operational control and learning concepts. The leadership and commitment management can be implemented in the brainstorming process. In order to improve it, there could be a coordinator of the session who makes sure every group member is heard and respected and sets a time limit to it.

The stage of operational control includes procedures of training and educating the personnel related to the project. The learning stage includes the “learning form past mistakes” approach and can be related to the statistical analysis mentioned above.

References

Lock, Dennis ; Project management

Ishikawa, Kaoru (1990); (Translator: J. H. Loftus); Introduction to Quality Control; 448 p; ISBN 4-906224-61-X OCLC 61341428

Dale, Barrie G. et al. (2007); Managing Quality 5th ed; ISBN 978-1-4051-4279-3 OCLC 288977828

http://www.academicjournals.org/app/webroot/article/article1380537568_Hekmatpanah.pdf