Project Quality Management

Quality processes should be used on all types of projects. As part of project triangle, project should be completed within time and cost, while maintaining high quality is very important for the successful outcome of the project. Worldwide competition has also resulted in a stronger emphasis on quality. If quality requirements are not met, it could lead to negative impact to both the customer and the company building the product or providing the service. The approach used to ensure quality can differ a lot between projects. For example, when developing a software there are other procedures then when developing a drug. To ensure quality satisfaction for the customer some Quality Management processes must be implemented. The quality management system consist of quality planning, quality assurance, and quality control. In this article we will look at how quality is defined and what are the best practices for managing quality to satisfy the customer and to meet quality standards.

Note that due to time constraints this article needs to add references in right format and also fixing photos..

Contents |

What is quality?

There is no single definition of quality, depending on who is asked quality can mean different things. The ISO definition for quality is “The quality of an organisations’ products and services is determined by the ability to satisfy customers and the intended and unintended impact on relevant interested parties.” and “ The quality of products and services includes not only their intended function and performance, but also their perceived value and benefit to the customer”.[1] Quality can also mean:[2]

- Relative quality - the product or service compared to other products or services.

- Fitness for use - the product or service is able to be used.

- Fitness for purpose - the product or service will meet its intended purpose.

- Meets requirements - the product or service in relation to the customer’s requirements.

- Quality is inherent - quality cannot be tested in. The process must support designing in quality, not attempting to test it in at the end of the process.

The lack of definition on this term causes troubles for the project manager, if they can’t describe precisely what quality improvements they are aiming for it will be difficult to implement quality improvement objectives.

| Manufacturing | Service | |

|---|---|---|

| Definition | Product-based, a precise and measurable set of characteristics | Based on stakeholders’ expectations and perceptions |

| Attributes | Performance, conformance features, reliability, durability, serviceability, perceived quality and aesthetics | Access, communication, competence courtesy, credibility reliability responsiveness, security, tangibles, understanding/knowing the customer |

Dimensions of quality for manufactured products:

- Performance - The basic operating characteristics of the product.

- Features - The “extra” items added to the basic features.

- Reliability - The probability that a product will operate properly within an expected time frame.

- Conformance - The degree to which a product meets pre established standards.

- Durability - How long is the product life span.

- Serviceability - The ease/speed of getting repairs.

- Aesthetics - How a product looks, feels, sounds, smells, or tastes.

- Safety - Assurance that the customer will not suffer injury or harm from a product.

Dimensions of quality for service

Quality in service is directly related to time and the interaction between employees and the customer. Evans and Lindsay identify the following dimension of service quality:[4]

- Time and timeliness - How long must a customer wait for service, and is it completed on time?

- Completeness - Is everything the customer asked for provided?

- Courtesy - How are customers treated by employees

- Consistency - Is the same level of service provided to each customer each time?

- Accessibility and convenience - How easy is it to obtain the service?

- Accuracy - Is the service performed right the first time?

- Responsiveness - How well does the company react to unusual situations, which can happen frequently in a service company?

Customer Focus

The primary focus of quality management is the customer. Since the organization depends on the customer, they should understand future needs as well as current ones. They also need to meet customer requirements and try to exceed their expectations where possible. The reason is simple, customers who are happy and delighted are less likely to switch to a competitor, which eventually translates into profit [5]. There are different approaches and techniques to achieving business excellence, to name a few; Total Quality Control, Quality Management, TQM, Process Improvement, Six Sigma, Business Process Management (BPM), Lean, Baldrige. They all have some common elements that are the keys to success. The most important element of quality is the customer. Therefore, products and services must be designed to meet customer expectations and needs for quality [5]. Organisations attain customer focus when all people in the organisation know what the customer requirements must be met to ensure all internal and external stakeholders are satisfied. All quality improvements should ultimately target improving the customer satisfaction. For this, the organisation can conduct surveys and feedback forums for gathering customer satisfaction and feedback information.[6]

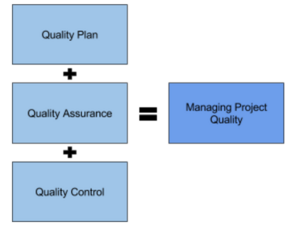

Managing project quality

The Quality Management processes implement the quality management system through the procedures and processes of quality planning, quality assurance, and quality control. This is a continuous process, improvement activities using quality techniques and tools throughout the project life cycle. If the requirements for the product of the project are consistent with real, or perceived, needs of the customer, then the customer is likely to be satisfied with the product of the project[2].

The quality plan defines the quality standards for the project must meet and how you will manage the compliance of deliverables. This requires agreeing with project sponsor and other stakeholders regarding objectives and standards to be achieved. Establishing tools and determine resources necessary to achieve quality standards.

Project quality assurance activities are an important aspect of building in quality rather than trying to test in quality at the end of the development life cycle. Quality assurance focus point is on continuous improvements of the process, reducing waste, allowing processes to operate at increased levels of efficiency[2]. During the quality assurance phase the project manager must ensure that objectives and standards to be achieved are communicated, understood and accepted by all appropriate stakeholders[1].

Performing quality control is where the monitoring and controlling of the project is required, to ensure the project adhere to relevant quality standards. This process should be used during the whole project life cycle to analyse unsatisfactory performance and find preventive actions. There are several methods for managing quality control using tools such as[7]:

- A cause and effect diagram: Identifies possible causes for an effect or a problem and sorts ideas into useful categories.

- Control Charts: Graphs used to study how a process changes over time. This approach is used when monitoring and tracking repetitive activities such as; cost, variances, volumes.

- Pareto Charts: Used when there are many problems or causes, to focus on which factors are the most significant.

- Inspections: Examines the project’s artifacts to determine conformance to standards and validate defect repairs.

There can be some confusion regarding quality assurance and quality control. The difference between those two is that quality assurance is part of the executing process and is concerned with making sure that objectives are followed. This process focus on continuous process improvement, which is an iterative means for improving the quality of all processes [8].

Continuous improvements

The Deming Wheel is a four-stage process for continuous quality improvement. It is also known as Plan-Do-Check-Act cycle (PDCA), and is a four-step management method used for continuous quality improvement of processes and products. This method complements with Deming’s 14 points and are the foundation for todays’s quality management systems employeed by many successful organisations[5].

- Plan

- Understanding the existing situation and study the process, identify the problem, collect data, set goal necessary to deliver results, and develop the plan for improvement. When analysing the current state, techniques such as 5 Whys or Ishikawa diagram can be used to help identifying the root cause.

- Do

- Implement the plan on a test basis and implement the solution, measure improvement.

- Check

- Assess the plan, measure and confirm the results with comparison of previous phase and expected targets to identify adjustments. Ask question such as; is it working? are goals achieved? Look for deviation from the plan in implementation and also look for the appropriateness and completeness of the plan to enable the execution. Collect data.

- Act

- Institutionalise improvement, document the solution and standardize. If the results were not successful, observe and learn what can be done better and adjust before starting the cycle again.

Implementation

-WIP-

Limitations

-WIP-

Cost of quality

Cost of quality is a concept that is often overlooked when planning the quality effort in a project. The term is used to reflect the total price of all efforts to achieve quality in a product or service.

Key project decisions that impact the cost of quality come from either striving for “zero” defects—how much it will cost the project to achieve this high level of quality, versus achieving “good enough” quality—which may result in costly product recall or warranty claims However, the impact of quality investments on profits cannot always be directly assessed because it usually is long-term; many other variables (price, distribution, competition, effectiveness, image and publicity) influence profits; and simply spending on quality does not automatically lead to profits because the strategy and functionality of the investment are also important (Zeithaml et al., 1996).

Cost of Good quality

Cost of Poor quality

The cost of poor quality is the total amount of money a company uses to prevent poor quality, plus any other costs incurred as a result of poor quality being produced. Cost of poor quality can be categorised as follows: (managing project quality, Timothy, 2002)

- Prevention costs

- Appraisal costs

- Failure costs

-WIP-

Benefits

Some potential Key benefits are:

- Increased customer value

- Increased customer satisfaction

- Improved customer loyalty

- Enhanced repeat business

- Enhanced reputation of the organization

- Expand customer base

- Increased revenue and market share.

-WIP-

Conclusion

Planning quality activities will ensure a high degree of project and product success, which will lead to a high return on investment for the effort invested in the project. Continuous improvement efforts are cross-functional in nature, so as long as a project has defined objectives and deliverables, there should be a project quality plan to measure the delivery and process quality. Quality improvements require active participation and approval from management. A total commitment to quality is necessary throughout an organization for it to be successful in improving and managing project quality. Employees must be active participants in the quality improvement process and must feel a responsibility for quality.

Reference

- ↑ 1.0 1.1 ISO9000,2015, Quality management systems - Fundamentals and vocabulary. International Organization for Standardization.

- ↑ 2.0 2.1 2.2 Paul Dinsmore (2011). The AMA handbook of project management’’. 3th edition, 123-139. New York. ISBN 978-0-8144-1542-9.

- ↑ Harvey Maylor (2010). Project management. 4th edition, 200-215. Harlow, England NY. ISBN 9780273704324.

- ↑ J.R. Evans and W.M Lindsay (1995). The management and control of quality. 3th edition, South-Western College Pub. ISBN 78-0-314-06215-4.

- ↑ 5.0 5.1 5.2 Roberta Russell (2011). Operations management : creating value along the supply chain’’. 7th edition, 61-99. Hoboken, N.J. Chichester. ISBN 9780470646236.

- ↑ Total Quality Management (TQM)”. [online] tutorialspoint.com. Available at: https://www.tutorialspoint.com/management_concepts/total_quality_management.htm [Accessed 16 Sep. 2016].

- ↑ Schulmeyer, G. Gordon & McManus, James I. (1996). Handbook of software quality assurance’’. 2th edition. Boston. ISBN 978-1-59693-186-2.

- ↑ Paul Newton (2015). ‘’Project Management Processes’’. ISBN 978-1-62620-959-6.

Annotated Bibliography

Tague, Nancy R. The Quality Toolbox (5th ed.). (1995). Milwaukee: ASQ Quality Press

This book describes the appropriate tools and methods for continuous improvements.