Comparison of Certifications for Sustainable Buidlings

Contents |

ABSTRACT

In construction, quality assurance (QA) can be defined as the “part of quality management focused on providing confidence that quality requirements will be fulfilled” (Winch, 2010). It includes all planned actions necessary to achieve a satisfactory performance, although it does not identify conformity or non-conformity.

Among the three basic systems to identify the procedures to follow, the third-party ones have now been proven to be the best practice as they follow international standards such as ISO. These systems consist of independent third parties that certify the QA system. Thus, many independent third parties such as Leadership in Energy and Environmental Design (LEED) and WELL Building Standard have emerged in the last 15 years. LEED certification provides independent verification of a building or neighborhood’s green features, allowing for the design, construction, operation and maintenance of resource-efficient, high-performing, healthy, cost-effective buildings. (LEED, 2017)

On the other hand, WELL is a performance-based system for measuring, certifying, and monitoring features of the built environment that impact human health and wellbeing, through air, water, nourishment, light, fitness, comfort, and mind. (WELL, 2017)

The aim of this report is to compare the requirements and goals of both certifications. However, since they have different approaches, it is expected that the connection between them will be of complementation rather than of exclusion.

INTRODUCTION

QUALITY MANAGEMENT SYSTEMS

Quality can be defined as “the degree to which a set of inherent characteristics fulfils requirements” (Winch, 2010). One of the objectives for the Quality Management Systems is to make clear that non-conformance in a product is somebody’s fault. Thus, workers are encouraged, reward-based, to take responsibility when achieving high quality. There are four main basic approaches to make sure that high quality has been reached and these act as complement rather than as alternatives: • Inspection: physical check. • Quality Control (QC): management control techniques. • Quality Assurance (QA): externally accredited procedures. • Total Quality Management: continuous process improvement.

QUALITY CONTROL

Quality Control is “a part of quality management focusing on fulfilling quality requirements” (ISO 9000, 2015) and consists of all the actions that have to be followed to reach high quality. Therefore, the product is verified according to the customer’s requirements until the output conformance reaches the desired quality levels. Some of the techniques include testing, inspections and walkthroughs.

QUALITY ASSURANCE

Quality Assurance can be defined as the “part of quality management focused on providing confidence that quality requirements will be fulfilled” (ISO 9000, 2015) by supplying a set of processes than can be applied to ensure high quality in the output. QA can be considered as a Strategy of Prevention for its main focus is to plan, document and set guidelines at an early stage of the project to prevent defects from penetrating into the solution (Arthur, 2017). Thus, engaging with QA already at the starting point of the project is crucial to reduce the risks identified in specification phases. According to (Winch, 2010), there are three basic types of QA: • First-party systems: are responsibility of the company concerned. • Second-party systems: suppliers are accredited by buyers using proprietary standards. • Third-party systems: consists of independent and certified third-party systems. Although the three systems are widely used, the third-party systems are now considered to be best practice for they usually follow the international standards developed by the International Organization for Standardization (ISO). Thus, many independent third-parties have emerged in the last 15 years.

THIRD-PARTY SYSTEMS

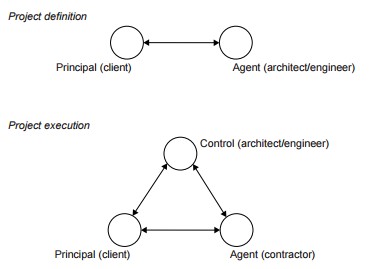

Third-party systems have advantage over the other two because they consist of an objective audit, not dependent on the company´s or personal interests. Its particular responsibility is to asses a quality system for conformance compared to the standard and issue the certification of conformance when the quality level is successful. Many parties are included in project execution, opposed to the project definition where only the client and the agent (an architect or engineer) are involved. In Figure 1, the third-party system for quality control is represented as “Control” and is included only in the project execution.

Figure 1. Professional System Diagram (Winch, 2010)

Figure 1. Professional System Diagram (Winch, 2010)

Since the third-party systems are the most frequent practice, many independent third parties such as Leadership in Energy and Environmental Design (LEED) and WELL Building Standard have emerged. As mentioned before and contrary to QC, QA is the process of managing for quality and it is not used to verify the quality of the output (Arthur, 2017). However, LEED and WELL fall into both categories because they focus on the managing process as well as in the quality verification of the output.

CERTIFICATIONS

LEED

One of the most widely used third-party certifications in the United States buildings is LEED, which stands for Leadership in Energy and Environmental Design and has been managed by The U.S. Green Building Council (USBGC) for the last 17 years. LEED not only focuses on the design and construction, but also gives considerable importance to the operation and maintenance areas.

Objective

The overall goal is to ensure resource efficiency by using less water and energy and reducing greenhouse gas emissions. Thus, as a side effect and bonus, it also contributes to saving money in both, construction and operation.

Focus Areas

LEED is organized to promote action in 6 key areas which are also known as credit categories:

• Location and transportation • Sustainable sites • Water efficiency • Energy & atmosphere • Material & resources • Indoor environmental quality • Innovation

However, these categories exist to help clients understand what a LEED project should accomplish:

Figure 2. LEED impact categories (Owens)

Project Types

It addresses to buildings everywhere, of any kind and at any phase of development because they have certifications for: • Building Design and Construction: new constructions or major renovations. • Interior Design and Construction: complete interior fit-out. • Building Operations and Maintenance: improvement work or little to no construction. • Neighborhood Development: land development projects (residential). • Homes: single family homes.

Evaluation Method

Projects that are aiming to get LEED certification earn points in several areas that are meant to address many sustainability issues. The following are the aspects that are considered when applying the final certification: • LEED prerequisites: minimum requirements that all buildings must achieve to acquire a LEED certification. • LEED credits: several credits from different sustainable areas that can be chosen by the project holder to earn points. The areas are the same as mentioned in 1.1.2. • LEED points: earned by the chosen credits that are addressed in the project.

Based on the earned points and according to LEED’s rating levels, a project may get one of the following certifications: • Certified: 40-49 points. • Silver: 50-59 points. • Gold: 60-79 points. • Platinum: 80+ points.

Certification Process

From the list of prerequisites, perhaps the most crucial one is the necessity of commissioning by a certified LEED AP (professional credential). Commissioning is a highly effective management method to improve the performance of building systems and equipment. It reduces problems and promotes satisfied buildings owners for it is a quality based process that consists of written documentation of facility planning thorough design review, physical inspection of all installed equipment and operational performance verification of mechanical electrical systems (Commissioning Solutions, 2017). The process of commissioning includes the pre-design process as well as the executive design, construction, operation and maintenance. The LEED AP of each project is an independent part of the building team and represents the client’s wishes. They must, however, have experience in all the areas of the construction process, for they work together with the architects, engineers and contractors. Figure X shows the correction costs across the opportunity for influence related to every phase of the construction process. Thus, LEED AP’s goals are to manage the project since an early stage to save the most and to establish strategies to reduce operation costs by focusing on the building operation life.

Figure 3. Project life costs and opportunity for influence (Mandelbaum, 2014)

WELL

WELL Building Standard is one of the leading tools that comprehensively address not only the design and operations of buildings, but also how they impact and influence human behaviors related to health and well-being. It consists of features across the following seven concepts: air, water, nourishment, light, fitness, comfort, mind and innovation.

Objective

Design and operation of buildings and their impact and influence on human behavior related to health and well-being.

Focus Areas

Air, water, nourishment, light, fitness, comfort, mind and innovation.

Project Types

Evaluation Method

Certification Process

In order to apply for WELL certification, a project must first be registered online. Basic information as well as the project scope and path need to be provided and Performance Verification needs to be scheduled (five years for projects utilizing WELL and three years for projects utilizing WELL pilot). Requests for extension of the period are only accepted one year prior to the registration expiration date. Projects are normally reviewed on the date they were registered.

After registration, a WELL Assessor is assigned to the project by the Green Business Certification Inc. (GBCI) with the responsibility of answering technical questions prior to submission and reviewing the project after the submission. Then, project team roles are assigned as follows: • Project Administration acting as a project manager and overseeing the WELL process; responsible for ensuring that all the project documentation is complete and accurate prior to submission • Owner – responsible for authorizing registration of the project and validating documents • Additional Signatories – responsible for overseeing relevant aspects of design construction or operation • WELL Accredited Professional (WELL AP) – guiding projects to successful certification Required document types: • Annotated Documents – existing project documents providing information on how WELL features have been met (design drawings, operations schedules, policy documents, etc.) • Letters of assurance – required from architects, contractors and engineers to verify the implementation of specific WELL features • General Documents – representative floor plans, mechanical drawings, description of project etc. All relevant project documentation and information for review is submitted to the WELL Online system. Within 20-25 days the WELL Assessor replies and indicates which features have been met and what additional information is needed. If some of the documents are unsatisfactory, the project team has a chance to provide further documentation for a second round review. Finally, the project team is notified via WELL Online if an approval is granted and if so, at which date Performance Verification can be scheduled. Performance Verification WELL report Award and continued engagement Innovations and alternative adherence paths Curative actions and appeals Precertification Recertification