4D-Planning in Construction Management

Building information modeling (BIM) is a process that came to revolutionize the work -flow of the AEC Industry. The fourth dimension of BIM focuses on linking the 3D geometrical models with time and scheduling. The visualization of the schedule using 4D planning methods enhances not only the Critical Space Analysis [1] which is part of the new approaches to project scheduling, but also facilitates decision making throughout planning and construction phase. The opportunities of 4D planning also improve procurement management and spatial constrains reinforcing and supplement the location-based scheduling. Another approach that gains more and more ground is the linkage of 4D BIM with the Lean construction practices [2]. This article investigates the values and benefits that 4D Planning intends to create simultaneously with the barriers and constrains that need to be addressed to minimize the cost and time of construction projects and maximize the benefits and effectiveness.

Contents |

Framework

Backround

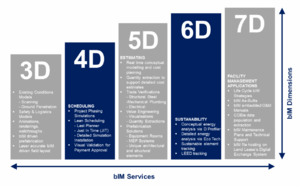

At the moment more than half of construction projects overcome their agreed time schedules deadlines [3] while using the conventional means of planning. Nowadays AEC Industry is in a transitional phase, where it tries to shift from "2D-based documentation and staged delivery processes to a digital prototype and collaborative work-flow" [2]. The enhancement of CAD capabilities intends to link design information with business processes [2]. Building information modeling is a digital representation of physical and functional characteristics [4] and a key process for this achievement. BIM process consists of 7 distentions that designate a more efficient way not only to design but also to plan, construct and manage buildings through a holistic approach and model-based information. Figure 1. shows the 7-dimensions of BIM.

4D-BIM Context

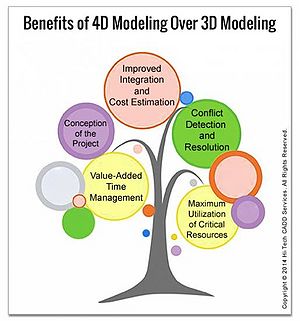

The rapid evolution of technology in conjunction with the high demand for an efficient time and cost planning of buildings, introduces BIM as one of the most promising implementations concerning Time management in AEC industry. 4D-Planning is a rising technique that combines the 3D CAD models with construction activities [5] in order to adequately bridge the gap between design, construction and scheduling. It is quite common by using the traditional methods of planning like Gantt Chart and The Critical Path Method (CPM) to address difficulties regarding synchronization either with the design or with the real time construction. BIM supports such methods of planning reinforcing the reliability of the schedule and creating accurate and detail Work Breakdown Structure (WBS) based on one source .

Three approaches have been developed utilizing the contribution of BIM in planning. The first is related to the association of time in the already existing building elements during design phase. More specifically, this can be achieved by specifying the construction phase of each individual element creating a construction sequence that can be easily visualized by virtual simulations of schedule [2]. Second, analysis tools can be used incorporating BIM components and construction method information with the view to enhance the activity sequence [2]. The last approach, concerns the association of 4D- planning with the Lean construction and especially in the Last Planner System.

Analysis

This section investigates the benefits and challenges of BIM implementation focusing on planning and scheduling. In addition, it explains how 4D-BIM affects and improves some of the most common planning methods such as Location based scheduling and Last Planner System

Advantages and Benefits

The concept of Building Information Modeling is already in use from AEC industry especially in design and construction sector, for some time now. However, for the Time Managements sector is a relatively new concept. How BIM achieves to improve the project planning can be divided in the following subsections.

Communication

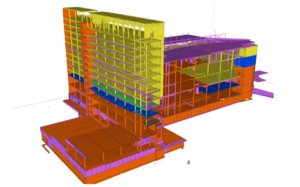

The visualization advantage that 4D- Planning offers, makes it one of the most important tools in terms of efficient communication among all the project stakeholders [2]. Exploiting the possibilities of capturing both temporal and spatial aspects of a schedule, contributes to an insight understanding of the time flow, minimizing misunderstandings. Furthermore, the different installation sequence can be easily simulated, creating animations [2]. Consequently, given the fact that a picture paints a thousand words, 4D tools can significantly enhance decision making as it becomes easier to identify and evaluate the currents situations. The jobsite coordination is also improved through visualization as it is quite common in the AEC industry different terminologies to be used. A common language through models and pictures may reduce these kinds of inconsistences. Owners and building users adequately understand the project milestones and the construction plans [7] . Figure 2. shows a visual representation of a BIM-based schedule using color coding, where Orange = completed/installed, blue = this week, green = next week, yellow = scheduled, in over two weeks, purple = scheduled.

Site management

Site logistics is undeniably a challenging sector in construction management. 4D- Planning let planners efficiently manage the site area. More specifically, the locations of large equipment, trailers and other either permanent or temporal facilities can be evaluated through the model [2] [7]. Connecting the 3d models with the construction activity schedules the manager is able to identify the critical space and sequencing requirements [7] . Figure 3. Shows how the building and the site can be simulated in order to ensure site access, trades stacking and storage locations [8]. With a site-space conflict analysis,the special constrains are identified and activities that my occur the same time in the same place can be avoided [2].

Time and cost

If the 4D- planning is successfully used, this tool is proved to be a valuable asset in terms of time and cost. It can reduce the time spend in rework [5] as the model can aggregates all the necessary information in one source and identify the unforeseen time conflicts beforehand minimizing the cost [8]. Therefore, the 4D BIM is directly pertinent and imperative condition for 5D BIM which links the cost estimation. The changes during the construction can be quickly incorporated in the model and then simulated for analysis and review [8].

Procurement

The Material requirements planning and management demands an accurate time schedule in order to achieve a successful material purchasing and tracking. Using a 4 dimensions BIM model, the related task schedule and the building elements are linked to predict the dates when elements have to be on site [7] . Apart from planning ahead the procurement method, tracking the status of services and materials by using additional parameters to the elements, associates the design with the procurement activities [2]. As a result, the impacts in the construction process due to procurement delays can be visually identified and forecasting the time and cost consequences.

Safety management

Human resources play a vital role in projects [8] [2]. A proper schedule as it has already mentioned, allows 4D simulations to influence the spatial constrains for people and protect them from possible accidents. The critical unsafe areas are recognized creating a safe and environment for the workers.

Quality of schedule

Undeniably, 4D planning enhances the overall quality of the schedule and consequently of the project. The schedule consists of numerous activities that their relationship and construction sequence is not always well planned [5]. Missing activities or relationships between them can be tracked through simulations, verifying the reliability of the schedule and Minimizing Risk and Uncertainties in Construction Projects. In addition, the construction progress is swiftly identified, with a direct and visual method, instead of the traditional bar charts [8].

Challenges and Barriers

As in every breakthrough there are challenges that need to be addressed in order to achieve a successful implementation. One of the most important prerequisites is the initial investment cost that is required. The set up of 4D-planning considered a relatively expensive investment at the beginning both in terms of software and implementation. Although, the final result expected to compensate the company [2]. Research have shown that the successful implementation of 4D-planning, results into 5% savings in cost growth, 4% savings in schedule growth and 65% reduction in rework [10]. However, companies still seem to hesitate due to lack of experience and knowledge pertaining to BIM technology [3]. Furthermore, 4D-BIM cannot improve the quality of a project planning if the initial planning competences are lacking.

Additionally, common targets need to be decided at the beginning of the project, creating a basis concerning the Level of detail of the model. Even if the AEC industry convinced to develop a better communication scheme, there are interoperability problems due to the different tools that the stakeholders use to create the model. An integral part of this chain is the creation of standards. The lack of determination concerning the required level of detail, impedes the efficiency. Little did we know regarding limitation and barriers of 4D BIM, by virtue of the fact that only few surveys have been conducted specialized on this topic [10]. Considering the limited research, a summation of the expected barriers is listed below[10]:

- Availability of competent staff

- Cost of software

- Cost of implementation

- Prevailing perception of lack of benefits for parties involved

- Limited universal use within projects

- Software interoperability issues

- Insufficiency of coding protocols for objects within the models' deficiency

- Coding standards for coding BIM software

- Lack of integrated models

- Time consuming [11]

- Unrealistic cost for small projects [11]

- Difficulties on keeping the models always updated in large and complex projects [11]

4D-Planning and Lean Construction

Location-Based Scheduling

The Location Based Scheduling (LBS), is a location-based technique of scheduling and planning the workflow in construction projects[12]. It is considered a promising alternative to activity-based scheduling method, such as CPM, combining the time of an activity with the location that this activity is expected to take place. Different techniques of LBS already exists, such as ‘Line-of-Balance’, ‘Flowline’, ‘Construction Planning Technique’etc. but their use remain limited.

Research revealed that the value of LBS, can be reinforced, implementing the 4D oriented planning approach. 4D-models offer a spatial insight in planning of construction activities that cannot be achieved for instance, if 2D drawings combined with the the LBS method [12]. The sequences of construction activities can be analyzed, taking into account the work crews, reducing time, conflicts and location inaccessibility[7]. Considering that LBS requires a location break down, which is a quite challenging process especially in large and complex projects, 4D simulation can identify the overlapping, in several locations, building elements [12]. However, the successful application of this combined method is demanding, as the different parties have to early decide and agreed in a location decomposition and the building elements need to be designed in pieces following the real-time construction process [7]. Last but not least, 5D BIM can be incorporated for quantities take off, creating a complete overview of the project. Figure

Last PLanner System

Critical Space Analysis

Reflection

References

- ↑ Winch, G. M., 2010, Managing Construction projects, second edition

- ↑ 2.00 2.01 2.02 2.03 2.04 2.05 2.06 2.07 2.08 2.09 2.10 2.11 Eastman, C.; Tiecholz, P.; Sacks, R.; Liston, K., 2008, "BIM Handbook: a Guide to Building Information Modeling for owners, managers, designers, engineers, and contractors"

- ↑ 3.0 3.1 Barry J. Gledson, David J. Greenwood, 2016. SURVEYING THE EXTENT AND USE OF 4D BIM IN THE UK [URL: http://www.itcon.org/papers/2016_4.content.02642.pdf]

- ↑ National Institute of Building Services (2014). \Frequently Asked Questions About the National BIM Standard-United States, National Standards-United States". Pat. [URL: https://web.archive.org/web/20141021154645/http://www.nationalbimstandard.org/faq.php] Retrieved on 9 June 2017.

- ↑ 5.0 5.1 5.2 Dawood, N. and Sikka, S., 2006 "The Value of Visual 4D Planning in the UK Construction Industry".University of Teesside, Middlesbrough

- ↑ COBIM Markku Jokela, Tuomas Laine Reijo Haanninen (2012). \Common BIM Requirements 2012, Use of Models in Facilities Management". Pat.

- ↑ 7.0 7.1 7.2 7.3 7.4 7.5 AU Workshop, Autodesk Univercity. 4D Simulation and Construction Planning[URL: http://auworkshop.autodesk.com/library/bim-curriculum-construction/4d-simulation-and-construction-planning], (Retrieved on 12 June 2017)

- ↑ 8.0 8.1 8.2 8.3 8.4 acePLP,Basics of 4D BIM. [URL: http://www.aceplp.com.sg/bim-cad/4d-bim-services] (Retrieved on 10 June 2017)

- ↑ 10.0 10.1 10.2 S. M. AHMED, H. H. EMAM AND P. FARRELL, 2014. "Barriers to BIM/4D Implementation in Qatar" [URL: file:///C:/Users/PC/Downloads/BIM%204D%20Barriers.pdf]

- ↑ 11.0 11.1 11.2 Mohamad Kassem, Trevor Brogden, Nashwan Dawood, 2012. "BIM and 4D planning: a holistic study of the barriersand drivers to widespread adoption"

- ↑ 12.0 12.1 12.2 Jongeling, R. & Olofsson, T (2006). A method for planning of work-flow by combined use of location-based scheduling and 4D CAD. Luleå University of Technology.

Annotated bibliography

- 1. Winch, G. M., 2010, Managing Construction projects, second edition

- 2. Eastman, C.; Tiecholz, P.; Sacks, R.; Liston, K., 2008, "BIM Handbook: a Guide to Building Information Modeling for owners, managers, designers, engineers, and contractors"

- Summary: